ماكينة التشكيل(الصبّ) بواسطة النفخ الأوتوماتيكية مجموعة L

الوصف والتفصيل

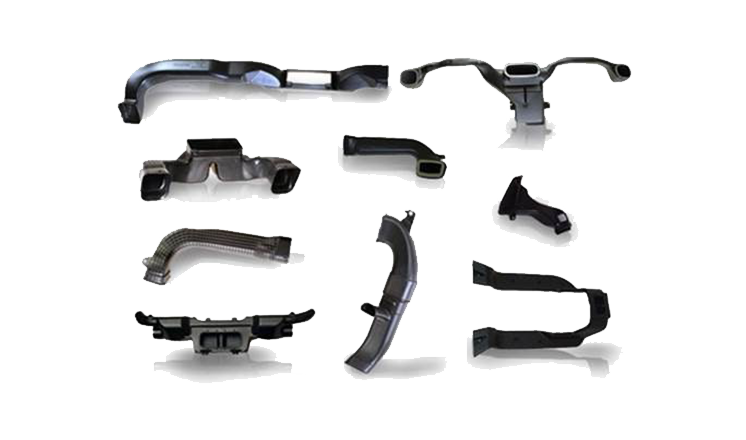

- مجموعة L لماكينات التشكيل(الصبّ) بواسطة النفخ مناسبة لإنتاج الأوعية البلاستيكية ذات الحجم الكبير، مثل خزانات المياه، الأسطوانات الكيميائية، غالونات جيري، وقطع السيارات البلاستيكية.

- تم تزويد هذه الماكينات برؤوس تشكيل وصبّ (مركم) ومتحكّمات باريزون متعددة النقاط(مضاعفة). تتحرك الناقلات بشكل عمودي وسهل لانتاج منتجات مختلفة الأشكال.

- الميزات

- Machine Model

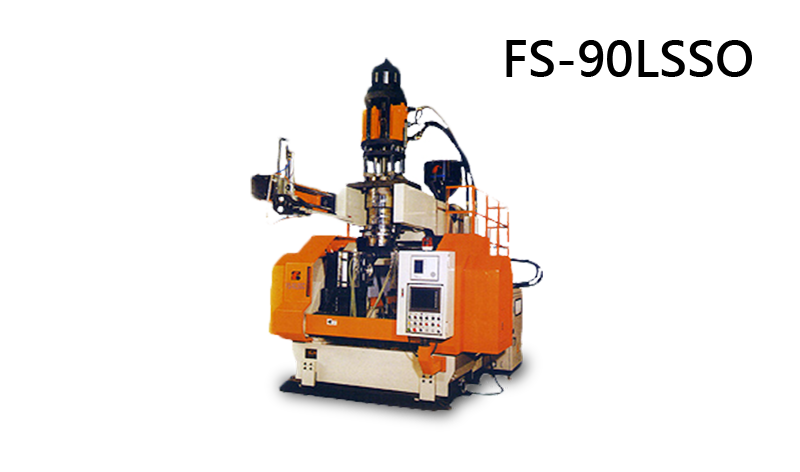

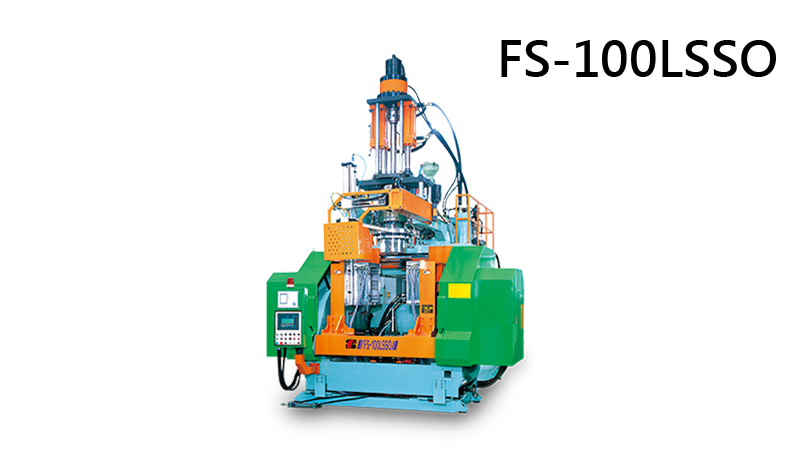

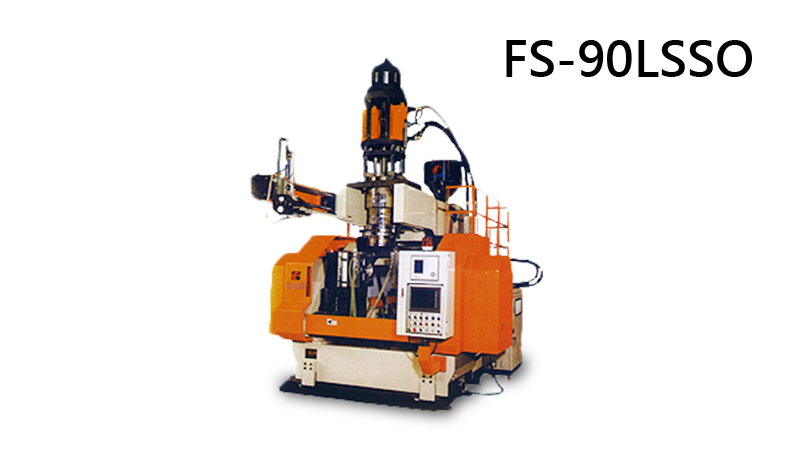

- L Series(Frontal Take-out Mechanism)

- الصور

- الميزات

- شاشة لمس LCD.

- أسطوانة وبرغي التليين تتمتع بالدقة وهس مزودة بستيل(معالجات نيتروجينية) خاصّة لمتانة التسخين والمقاومة.

- أيدي(أذرع) آلية مُبتكرة تستطيع اخذ وتحريك المنتج(الزجاجات) بعد الانتهاء من التصنيع أوتوماتيكيّاً.

- متحكّم نظام تبريد مائي للتغذية الحرارية.

- تمتلك آلية دبّوس النفخ دائرة تبريد خاصة ودقيقة.

- يتراوح مدى القدرة الإنتاجية من 30لتر وحتى 50لتر.

- نظام سلامة عامة(وقاية) مثبت بشكل جيد يقوم بحماية المشغّل(العامل) من أي خطر أو حادثة قد تحدث في عمل الماكينة.

- نظام توزيع هيدروليكي منفصل وفعّال لعملية الشدّ والعمليات الميكانيكية الأخرى.

| EXPOSITION OF FULL SHINE'S MACHINE MODEL |

| SCREW DIAMETER(M/M) | MACHINE SERIES | MOLD HEAD(DIE HEAD) | MOLD STATION | PRODUCT TYPE | |

|---|---|---|---|---|---|

| FS- | 40 | (H) Horizontal | (S) Single Mold Head | (S) Single Mold Station | (O) Original |

| 45 | (P) Parallel | (D) Double Mold Heads | (D) Double Mold Stations | (C) Two Colors | |

| 55 | (O) Standard / Oblique | (T) Three Mold Heads | (D) Two Layers | ||

| 65 | (A) Pneumatic | (F) Four Mold Heads | (T) Three Layers | ||

| 75 | (L) Frontal | (E) Eight Mold Heads | (F) Four Layers | ||

| 80 | (I) Lateral | (L) Six Layers | |||

| 90 | (V) View Stripe | ||||

| 100 | (P) PC baby bottle | ||||

| Example | |||||

| FS- | 65 | P | D | S | D |

| Model | FS-75LSSO | FS-80LSSO | FS-90LSSO | FS-100LSSO | FS-120LSSO | ||

|---|---|---|---|---|---|---|---|

| Material | PE | PE | PE | PE | PE | ||

| 1 | Product capacity | Liter | 1-10 | 10-30 | 30-50 | 50-100 | 100-250 |

| 2 | Diameter of Product | m/m | 80-260 | 120-350 | 150-400 | 180-580 | 260-650 |

| 3 | Screw diameter | m/m | 75 | 80 | 90 | 100 | 120 |

| 4 | Screw L/D ratio | L/D | 24/1 | 24/1 | 24/1 | 28/1 | 28/1 |

| 5 | Extruding capacity | Kg/hr | 100 | 120 | 140 | 210 | 270 |

| 6 | Accumulator | Kg | 2.5 | 2.5 | 5 | 7-12 | 26 |

| 7 | Screw Drive Inverter motor | HP | 30 | 40 | 50 | 60 | 100 |

| 8 | Screw Drive Hydraulic motor | C.C. | 1450 | 2000 | 2500 | 3000 | 4500 |

| 9 | Screw ration speed | r.p.m | 15-65 | 20-65 | 20-65 | 20-65 | 20-65 |

| 10 | Oil Hydraulic drive Inverter motor | HP | 25 | 30 | 30 | 40 | 75 |

| 11 | Oil Hydraulic drive Hydraulic motor | HP | 20 | 50 | 75 | 100 | 125 |

| 12 | Power of thickness control | HP | 5 | 5 | 7.5 | 10 | 10 |

| 13 | Air compressor(Optional) | HP | 7.5 | 15 | 15 | 20 | 30 |

| 14 | Pressure of air | kg/cm2 | 5-7 | 5-7 | 6-8 | 6-8 | 6-8 |

| 15 | Clamping force | ton | 28 | 42 | 50 | 100 | 162 |

| 16 | Oil tank capacity | Gallon | 80 | 100 | 140 | 200 | 210 |

| 17 | Number of heaters | Zone | 6 | 7 | 7 | 10 | 10 |

| 18 | Heating capacity | Kw | 26 | 28 | 32 | 36 | 45 |

| 19 | Total installed power | Kw | 68 | 81 | 92 | 111 | 176 |

| 20 | Extruding mouth outer diameter | m/m | 200 | 280 | 350 | 450 | 650 |

| 21 | Open close daylight | m/m | 200-700 | 230-930 | 340-1000 | 360-1200 | 500-2300 |

| 22 | Length of mold capacity | m/m | 680 | 775 | 850 | 1200 | 1500 |

| 23 | Width of mold capacity | m/m | 500 | 640 | 820 | 1000 | 1300 |

| 24 | Machine water consumption | L/hr | 900 | 900 | 1000 | 1200 | 1500 |

| 25 | Mold water consumption | L/min | 230 | 230 | 230 | 230 | 450 |

| kcal/hr | 31500 | 31500 | 46623 | 46623 | 246500 | ||

| 26 | Machine net weight | ton | 7.2 | 11 | 12 | 18 | 32 |

| 27 | Machine dimension<L*W*H> | m | 3.4*2.5*2.8 | 3.8*2.8*2.8 | 5*3*3.3 | 5.5*3.5*3.3 | 5.7*9.6*6 |

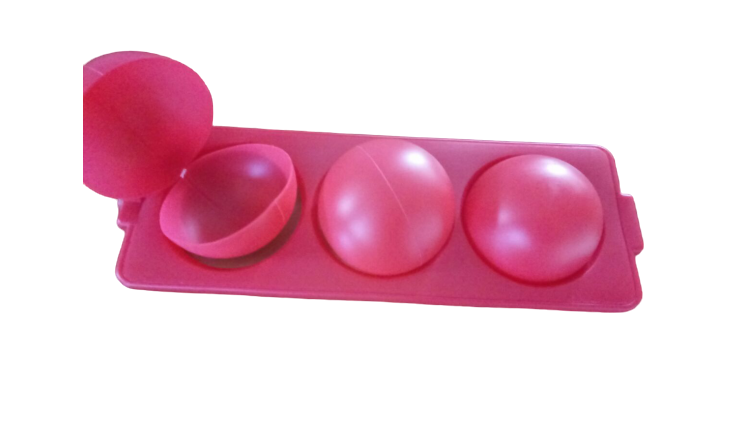

Sample bottles

Sample bottles

Sample bottles

Sample bottles

الوضعية

Watering cans

Automotive

210L~250L Double L ring drum

Gardening supplies

Ice bucket / Ice box

Seat cushion

Outdoor supplies/Bird balls

Water tank