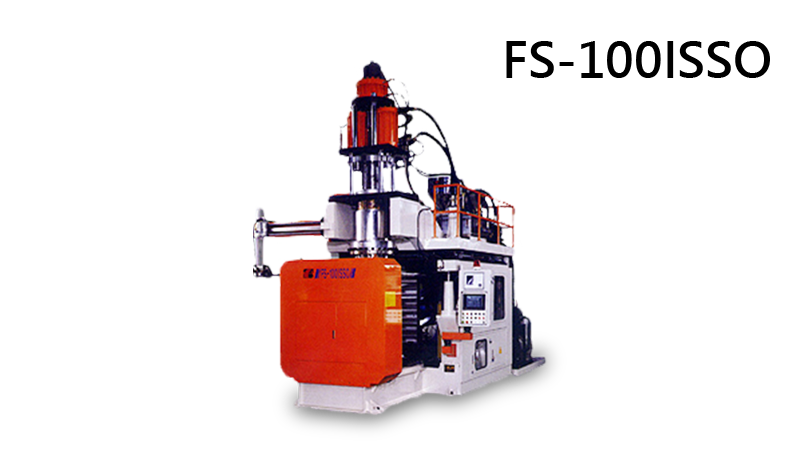

Accumulator Head Type Blow Molding Machine I Series

Descripton

These machines are equipped with accumulator-type mold heads and multi-point parison controllers. These machines are with lateral take-out mechanism. Machine frame and die head are movable for replacing molds easily.

- Apply for single station

- Production volume: from 10L-1000L

- Cavities: 1 cavity

- Apply for PE/PP /ABS/PA…

- Support: Hybrid system, Parison control, turn key solution

- Features

- Machine Model

- I Series(Lateral Take-out Mechanism)

- PHOTOS

- Video

- Features

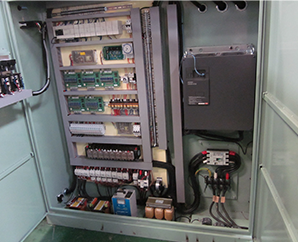

- LCD Touch Screen connects to each mechanical and electric function, and has the self-diagnostic system easy for troubleshooting and adjustment.

- The plasticizing screw and barrel are precision components with special nitrogen-treated steel for heat durability and resistance.

- Water cooling system controls the feeding-zone temperature.

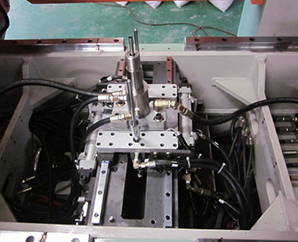

- Blow pin unit has a special and accurate cooling circulation and hydraulic-driven system. (Bottom Blow Unit).

- Product capacity’s range is from 30 Liter to 50 Liter.

- Fully-interlocked pneumatic, hydraulic and electric safety devices to protect operators from danger and accident. We can also equip machines with light curtains for additional protection.

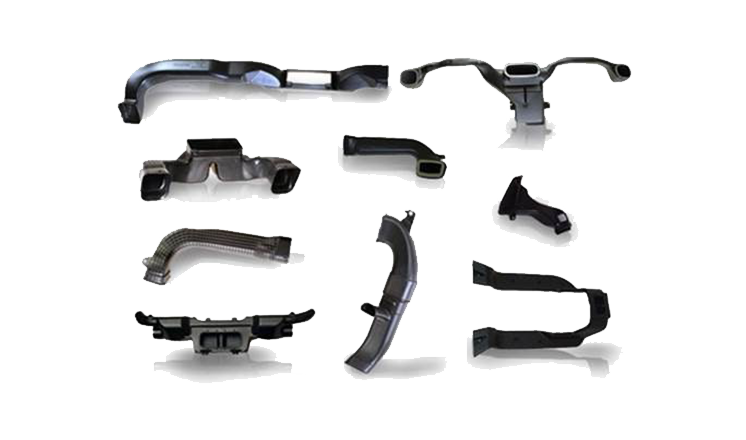

- I Series machines are suitable for producing various and different-shape of plastic products.

- For high-efficient extrusion, the screw with high mixing combines with gear box, made in Germany, and inverter, made in Japan, which can adjust screw ration speed and reduce power wastage. Unlike using tradition hydraulic motor driving system, it reduces 40% usage of hydraulic oil.

- Extrusion platen can be adjusted up and down, leftwards and rightwards by the control of hydraulic motor. Extrusion platen is capable of height adjustment for producing picnic table, air ducts, auto parts, and so on.

- Die head is with special -designed core, hydraulic controlled injection piston and cylinder, and First in and First out design, which is capable of fast accumulation and shortens the time of changing color. To equip MOOG parison wall thickness controller and servo cylinder is good for extruding equal thick parison.

- Close and open mold is controlled by linear slide way, make in Germany, for accurate positioning and stable carriage movement. Mold carriage is equipped with light curtain/ electric eye protection, and safety gate.

- Blow pin movement is hydraulic-driven with water-cooling design. This machine is also with bottom blowing and side blowing option. Parison enlarger is pneumatic-driven, which makes equivalent products shape, suitable for blow molding huge containers.

- Optional robot arm is with water cooling design to avoid material stick, and is capable of taking our heavy products automatically. The material is light aluminum alloy. The movement of robot arm is controlled by linear slide way, which reduces friction and use of power driving.

- Mold carriage is operated by double piston cylinder. Sub Cylinder speed up mold close, and Main Cylinder is driven with higher clamping force. Carriage movement is controlled by slide rails for easy mold changing. Special-designed mold core-pull function is suitable for making concave products, such as handle jerry cans, expelling products rapidly.

- With guide bar of molds clamping, the mold platens are with equal clamping force, without the concern of platen deformation. Top and bottom clamping force is with main-cylinder design.

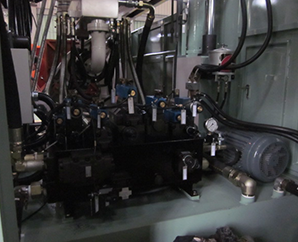

- Hydraulic system is YUKEN hydraulic valves with proportional flow and proportional pressure control circuit, which can be adjusted based on different products features. Separate and airtight oil tank maintains oil purity, or collocate Full Shine oil cleaner for good and long-term use of hydraulic oil.

- Separate control cabinet is equipped with Fuji 10.4” colorful HMI, easy for data setting, temperature control, and parison control with detailed information for adopting various products. Error message and 50 sets of memory saving are use-friendly.

| EXPOSITION OF FULL SHINE'S MACHINE MODEL |

| SCREW DIAMETER(M/M) | MACHINE SERIES | MOLD HEAD(DIE HEAD) | MOLD STATION | PRODUCT TYPE | |

|---|---|---|---|---|---|

| FS- | 40 | (H) Horizontal | (S) Single Mold Head | (S) Single Mold Station | (O) Original |

| 45 | (P) Parallel | (D) Double Mold Heads | (D) Double Mold Stations | (C) Two Colors | |

| 55 | (O) Standard / Oblique | (T) Three Mold Heads | (D) Two Layers | ||

| 65 | (A) Pneumatic | (F) Four Mold Heads | (T) Three Layers | ||

| 75 | (L) Frontal | (E) Eight Mold Heads | (F) Four Layers | ||

| 80 | (I) Lateral | (L) Six Layers | |||

| 90 | (V) View Stripe | ||||

| 100 | (P) PC baby bottle | ||||

| Example | |||||

| FS- | 65 | P | D | S | D |

| Model | FS-75ISSO | FS-80ISSO | FS-90ISSO | FS-100ISSO | ||

|---|---|---|---|---|---|---|

| Material | PE | PE | PE | PE | ||

| 1 | Product capacity | Liter | 1-10 | 10-30 | 30-50 | 50-100 |

| 2 | Diameter of Product | m/m | 80-260 | 120-350 | 150-400 | 150-580 |

| 3 | Screw diameter | m/m | 75 | 80 | 90 | 100 |

| 4 | Screw L/D ratio | L/D | 24/1 | 24/1 | 24/1 | 28/1 |

| 5 | Extruding capacity | Kg/hr | 100 | 120 | 140 | 180 |

| 6 | Accumulator | Kg | 2.5 | 2.5 | 5 | 7-12 |

| 7 | Screw Drive Inverter motor | HP | 30 | 40 | 50 | - |

| 8 | Screw Drive Hydraulic motor | C.C. | - | 2000 | 2500 | 3000 |

| 9 | Screw ration speed | r.p.m | 15-65 | 20-65 | 20-65 | 20-65 |

| 10 | Oil Hydraulic drive Inverter motor | HP | 15 | 25 | 30 | 40 |

| 11 | Oil Hydraulic drive Hydraulic motor | HP | 15 | 50 | 60 | 75 |

| 12 | Power of thickness control | HP | 5 | 5 | 7.5 | 10 |

| 13 | Air compressor(Optional) | HP | 7.5 | 15 | 15 | 20 |

| 14 | Pressure of air | kg/cm2 | 5-7 | 5-7 | 6-8 | 6-8 |

| 15 | Clamping force | ton | 28 | 32 | 44 | 85 |

| 16 | Oil tank capacity | Gallon | 80 | 100 | 140 | 200 |

| 17 | Number of heaters | Zone | 6 | 7 | 7 | 10 |

| 18 | Heating capacity | Kw | 26 | 28 | 32 | 36 |

| 19 | Total installed power | Kw | 60 | 77 | 92 | 111 |

| 20 | Extruding mouth outer diameter | m/m | 200 | 280 | 350 | 450 |

| 21 | Open close daylight | m/m | 160-670 | 200-800 | 340-850 | 400-1000 |

| 22 | Length of mold capacity | m/m | 200-450 | 300-800 | 850 | 950 |

| 23 | Width of mold capacity | m/m | 450 | 630 | 750 | 1000 |

| 24 | Machine water consumption | L/hr | 900 | 900 | 1000 | 1200 |

| 25 | Mold water consumption | L/min | 230 | 230 | 230 | 230 |

| kcal/hr | 31500 | 31500 | 46623 | 46623 | ||

| 26 | Machine net weight | ton | 7.2 | 11 | 12 | 18 |

| 27 | Machine dimension<L*W*H> | m | 3.8*2.6*2.8 | 4.5*2.6S*2.8 | 5*3*3.3 | 5.5*3.5*3.3 |

Sample bottles

Sample bottles

Bottom blowing system

Close and open mold is controller by linear slide way, make in Germany

FS-90ISSO machine outlooking

Hydraulic system

.png)

Machine outlooking

.png)

Machine outlooking

Machine outlooking

PLC control cabinet is equipped with Fuji 10.4” colorful HMI

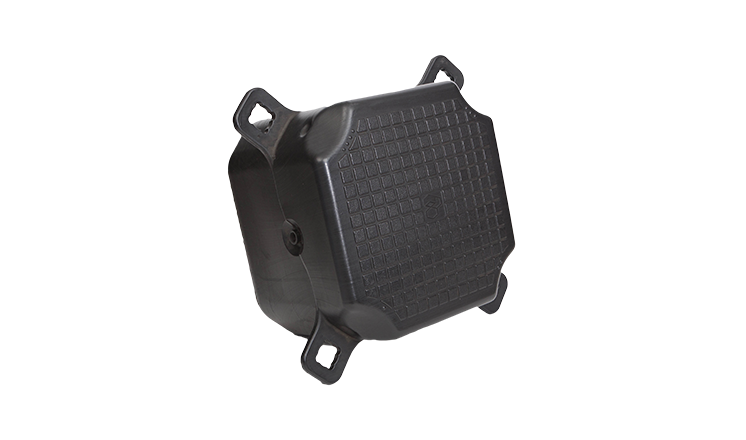

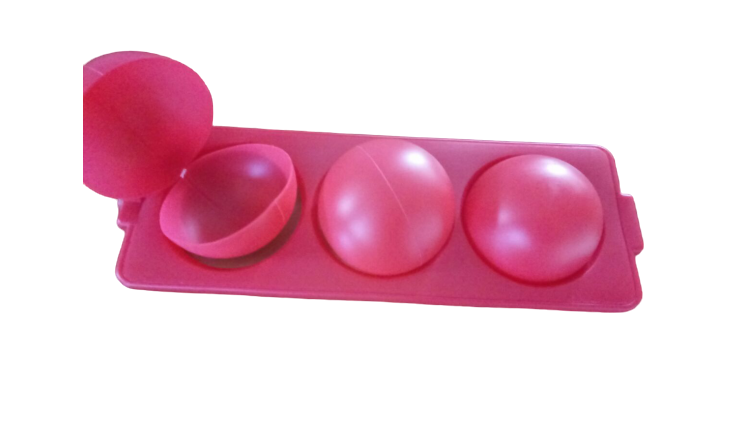

Application

Watering cans

Automotive

210L~250L Double L ring drum

Blow Molded Plastic Bucket

Floating bucket

Seat cushion

Outdoor supplies/Bird balls

Water tank

Household/Cosmetics