Automatic Blow Molding Machine O Series

Descripton

- ● Apply for single station/ double station

- ● Production volume: from 2ml-10L

- ● Mono layer and multi layers are available

- ● Cavities: 1~6 cavities

- ● Apply for PE/PP/PETG/PVC/ABS/PA/ PS/ Co-extrusion material

- ● Option: view stripe line

- ● Support: Hybrid system, Parison control, auto deflashing, turn key solution

Our automatic blow molding machine is the perfect solution for businesses that need to produce a wide variety of plastic products. With a production volume of 2ml to 10L, single-station or double-station configurations, and support for hybrid system, parison control, auto deflashing, and turnkey solution, our machine is the perfect choice for businesses of all sizes.

- PRODUCT FEATURE

- Machine Model

- Single Die-head/Single Station

- Double Die-head/Single Station

- Three Die-head/Single Station

- Four Die-head/Single Station

- Single Die-head/Double Station

- Double Die-head/Double Station

- Three Die-head/Double Station

- Four Die-head/Double Station

- PHOTOS

- Video

- PRODUCT FEATURE

- Carriage movement by tie bars with hydraulic system to move as V-type oblique movement. ■ Screw drive in the control of direct-mounted gear box and inverter motor as power saving Featur.

- HMI touch screen (10.4”) from Japan, Fuji, incorporating with PLC system for easy maintenance. ■ Blowing unit driven by hydraulic motor for changing mold easily-- innovative design.

- Equipped with auto cutting device, conveyor, parison wall thickness controller as option. ■ High-efficient plasticizing extrusion screw for processing materials completely.

■ Die head unit with head-lifted device for cutting melted material swiftly and for easy alignment adjustment.

■ Blowing unit, capable of equipping pre-lift feature to form small bottle neck precisely.

■ Full shine special-designed brake system for the carriage to provide stable movement and swift positioning.

■ Close-loop system with servo motor and servo circuit for mold carriage movement, as option.

| EXPOSITION OF FULL SHINE'S MACHINE MODEL |

| SCREW DIAMETER(M/M) | MACHINE SERIES | MOLD HEAD(DIE HEAD) | MOLD STATION | PRODUCT TYPE | |

|---|---|---|---|---|---|

| FS- | 40 | (H) Horizontal | (S) Single Mold Head | (S) Single Mold Station | (O) Original |

| 45 | (P) Parallel | (D) Double Mold Heads | (D) Double Mold Stations | (C) Two Colors | |

| 55 | (O) Standard / Oblique | (T) Three Mold Heads | (D) Two Layers | ||

| 65 | (A) Pneumatic | (F) Four Mold Heads | (T) Three Layers | ||

| 75 | (L) Frontal | (E) Eight Mold Heads | (F) Four Layers | ||

| 80 | (I) Lateral | (L) Six Layers | |||

| 90 | (V) View Stripe | ||||

| 100 | (P) PC baby bottle | ||||

| Example | |||||

| FS- | 65 | P | D | S | D |

| MODEL | FS-40 OSSO | FS-45 OSSO | FS-55 OSSO | FS-65 OSSO | FS-75 OSSO |

| Material | PE/PP | PE/PP | PE/PP | PE/PP | PE/PP |

| Screw diameter(m/m) | 40 | 45 | 55 | 65 | 75 |

| Screw L/D ratio(L/D) | 24/1 | 24/1 | 24/1 | 24/1 | 24/1 |

| Screw R.P.M speed(r.p.m.) | 20-66 | 15-61 | 15-60 | 15-60 | 15-58 |

| Inveter motor(HP) | 5 | 7.5 | 10 | 15 | 25 |

| Oil hydraulic drive motor(HP) | 5 | 7.5 | 10 | 10 | 15 |

| Optional air compressor(HP) | 5 | 5 | 7.5 | 7.5 | 10 |

| Air pressurer(kg/cm2) | 4-6 | 4-6 | 4-6 | 5-7 | 5-7 |

| Clamping force(Ton) | 2.8 | 3.9 | 4.4 | 6.9 | 10 |

| Oil tank capacity(Gallon) | 38 | 55 | 60 | 80 | 120 |

| Nunber of heaters(ZONE) | 4 | 4 | 4 | 5 | 5 |

| Heating capacity(KW) | 7 | 9.5 | 12.5 | 16.8 | 18 |

| Total installed power(KW) | 15 | 21 | 30 | 35 | 48 |

| Extruding capacity per hour(kg/hr) | 15 | 24 | 36 | 55 | 75 |

| Dry cycle per hour(time/hr) | 1285 | 1030 | 880 | 720 | 650 |

| Product capacity(c.c./L) | 15-500 | 60-1000 | 150-2500 | 500-5000 | 1L-10L |

| Product weight(g.) | 5-40 | 10-100 | 20-170 | 40-280 | 80-500 |

| Min./Max. diameter of product(m/m) | 10-75 | 20-100 | 30-140 | 50-200 | 80-260 |

| Extruding mouth outer diameter(m/m) | 50 | 56 | 80 | 150 | 200 |

| Mold center distance(m/m) | * | * | * | * | * |

| Clamping distance(m/m) | 120-230 | 130-320 | 140-410 | 150-540 | 160-670 |

| Length of mold capacity(m/m) | 100-210 | 126-232 | 156-292 | 200-380 | 240-421 |

| Width of mold capacity(m/m) | 200 | 290 | 306 | 350 | 425 |

| Machine net weight(kg) | 2200 | 2700 | 3200 | 4100 | 7000 |

| Machine dimension(m) | 2.3*1.4*2.2 | 3*1.4*2.3 | 3*1.5*2.3 | 3*1.6*2.6 | 4.2*1.7*2.7 |

| MODEL | FS-40 ODSO | FS-45 ODSO | FS-55 ODSO | FS-65 ODSO | FS-75 ODSO |

| Material | PE/PP | PE/PP | PE/PP | PE/PP | PE/PP |

| Screw diameter(m/m) | 40 | 45 | 55 | 65 | 75 |

| Screw L/D ratio(L/D) | 24/1 | 24/1 | 24/1 | 24/1 | 24/1 |

| Screw R.P.M speed(r.p.m.) | 20-66 | 15-61 | 15-60 | 15-60 | 15-58 |

| Inveter motor(HP) | 5 | 7.5 | 10 | 15 | 40 |

| Oil hydraulic drive motor(HP) | 5 | 7.5 | 10 | 10 | 20/15 |

| Optional air compressor(HP) | 5 | 5 | 7.5 | 7.5 | 10 |

| Air pressurer(kg/cm2) | 4-6 | 4-6 | 4-6 | 5-7 | 5-7 |

| Clamping force(Ton) | 2.8 | 3.9 | 4.4 | 6.9 | 10 |

| Oil tank capacity(Gallon) | 38 | 55 | 60 | 80 | 120 |

| Nunber of heaters(ZONE) | 6 | 6 | 7 | 8 | 9 |

| Heating capacity(KW) | 7.5 | 10.25 | 13.6 | 17.5 | 25 |

| Total installed power(KW) | 15 | 21 | 30 | 35 | 48 |

| Extruding capacity per hour(kg/hr) | 15 | 24 | 36 | 55 | 75 |

| Dry cycle per hour(time/hr) | 1285 | 1030 | 880 | 720 | 650 |

| Product capacity(c.c./L) | 15-500 | 40-500 | 100-1250 | 280-1800 | 0.5L-2.5L |

| Product weight(g.) | 4-25 | 5-40 | 10-100 | 20-170 | 40-170 |

| Min./Max. diameter of product(m/m) | 10-65 | 20-70 | 30-85 | 40-100 | 40-130 |

| Extruding mouth outer diameter(m/m) | 38 | 42 | 50 | 65 | 80 |

| Mold center distance(m/m) | 85 | 100 | 120 | 140 | 180 |

| Clamping distance(m/m) | 120-230 | 130-320 | 140-410 | 150-540 | 160-670 |

| Length of mold capacity(m/m) | 100-210 | 126-232 | 156-292 | 200-380 | 240-421 |

| Width of mold capacity(m/m) | 200 | 290 | 306 | 350 | 425 |

| Machine net weight(kg) | 2200 | 2700 | 3200 | 4100 | 7000 |

| Machine dimension(m) | 2.3*1.4*2.2 | 3*1.4*2.3 | 3*1.5*2.3 | 3*1.6*2.6 | 4.2*1.7*2.7 |

| MODEL | FS-40 OTSO | FS-45 OTSO | FS-55 OTSO | FS-65 OTSO | FS-75 OTSO |

| Material | PE/PP | PE/PP | PE/PP | PE/PP | PE/PP |

| Screw diameter(m/m) | 40 | 45 | 55 | 65 | 75 |

| Screw L/D ratio(L/D) | 24/1 | 24/1 | 24/1 | 24/1 | 24/1 |

| Screw R.P.M speed(r.p.m.) | 20-66 | 15-61 | 15-60 | 15-60 | 15-58 |

| Inveter motor(HP) | 5 | 7.5 | 10 | 15 | 25 |

| Oil hydraulic drive motor(HP) | 5 | 7.5 | 10 | 10 | 15 |

| Optional air compressor(HP) | 7.5 | 7.5 | 10 | 10 | 15 |

| Air pressurer(kg/cm2) | 4-6 | 4-6 | 5-7 | 5-7 | 5-7 |

| Clamping force(Ton) | 2.8 | 3.9 | 4.4 | 6.9 | 10 |

| Oil tank capacity(Gallon) | 38 | 55 | 60 | 80 | 120 |

| Nunber of heaters(ZONE) | 8.5 | 12 | 15 | 19.3 | 21.5 |

| Heating capacity(KW) | 7.5 | 10.25 | 13.6 | 17.5 | 25 |

| Total installed power(KW) | 16.5 | 23.5 | 32 | 39 | 52.5 |

| Extruding capacity per hour(kg/hr) | 15 | 24 | 36 | 55 | 75 |

| Dry cycle per hour(time/hr) | 1250 | 1000 | 850 | 720 | 650 |

| Product capacity(c.c./L) | 10-125 | 20-325 | 40-825 | 100-1000 | 180-4500 |

| Product weight(g.) | 3-10 | 5-25 | 10-50 | 10-90 | 15-145 |

| Min./Max. diameter of product(m/m) | 10-45 | 20-55 | 30-55 | 30-80 | 95 |

| Extruding mouth outer diameter(m/m) | 30 | 37 | 40 | 55 | 80 |

| Mold center distance(m/m) | 75+75 | 85+85 | 100+100 | 120+120 | 120+120 |

| Clamping distance(m/m) | 120-230 | 130-320 | 140-410 | 150-540 | 160-670 |

| Length of mold capacity(m/m) | 100-210 | 126-232 | 156-292 | 200-380 | 243-466 |

| Width of mold capacity(m/m) | 200 | 290 | 306 | 350 | 425 |

| Machine net weight(kg) | 2500 | 3100 | 3600 | 4600 | 7500 |

| Machine dimension(m) | 2.3*1.4*2.2 | 3*1.4*2.3 | 3*1.5*2.3 | 3*1.6*2.6 | 4.2*1.7*2.7 |

| MODEL | FS-55 OFSO | FS-65 OFSO | FS-75 OFSO | FS-90 OFSO |

| Material | PE/PP | PE/PP | PE/PP | PE/PP |

| Screw diameter(m/m) | 55 | 65 | 75 | 90 |

| Screw L/D ratio(L/D) | 24/1 | 24/1 | 24/1 | 28/1 |

| Screw R.P.M speed(r.p.m.) | 15-60 | 15-60 | 15-58 | 15-58 |

| Inveter motor(HP) | 15 | 20 | 30 | 50 |

| Oil hydraulic drive motor(HP) | 10 | 15 | 15 | 15 |

| Optional air compressor(HP) | 15 | 15 | 20 | 20 |

| Air pressurer(kg/cm2) | 6-8 | 6-8 | 6-8 | 6-8 |

| Clamping force(Ton) | 4.4 | 6.9 | 10 | 13 |

| Oil tank capacity(Gallon) | 60 | 80 | 120 | 250 |

| Nunber of heaters(ZONE) | 11 | 13 | 13 | 15 |

| Heating capacity(KW) | 16.5 | 20.8 | 25.7 | 30 |

| Total installed power(KW) | 37.5 | 48 | 61 | 80 |

| Extruding capacity per hour(kg/hr) | 36 | 55 | 75 | 100 |

| Dry cycle per hour(time/hr) | 750 | 750 | 650 | 650 |

| Product capacity(c.c./L) | 30-300 | 100-500 | 300-1000 | 500-2500 |

| Product weight(g.) | 10-25 | 10-40 | 15-90 | 40-170 |

| Min./Max. diameter of product(m/m) | 20-55 | 30-55 | 30-90 | 30-90 |

| Extruding mouth outer diameter(m/m) | 37 | 42 | 50 | 75 |

| Mold center distance(m/m) | 85+85+85 | 85+85+85 | 120+120+120 | 120+120+120 |

| Clamping distance(m/m) | 140-410 | 150-540 | 160-670 | 200-780 |

| Length of mold capacity(m/m) | 156-292 | 200-380 | 243-466 | 250-550 |

| Width of mold capacity(m/m) | 380 | 430 | 510 | 550 |

| Machine net weight(kg) | 3800 | 4800 | 7900 | 8900 |

| Machine dimension(m) | 3.1*1.8*2.3 | 3.2*1.9*2.6 | 4.3*2*2.7 | 5.2*3.1*3.5 |

| MODEL | FS-45 OSDO | FS-55 OSDO | FS-65 OSDO | FS-75 OSDO |

| Material | PE/PP | PE/PP | PE/PP | PE/PP |

| Screw diameter(m/m) | 45 | 55 | 65 | 75 |

| Screw L/D ratio(L/D) | 24/1 | 24/1 | 24/1 | 24/1 |

| Screw R.P.M speed(r.p.m.) | 15-61 | 15-60 | 15-60 | 15-58 |

| Inveter motor(HP) | 7.5 | 10 | 15 | 30 |

| Oil hydraulic drive motor(HP) | 7.5 | 10 | 10 | 15 |

| Optional air compressor(HP) | 10 | 15 | 15 | 20 |

| Air pressurer(kg/cm2) | 4-6 | 4-6 | 5-7 | 5-7 |

| Clamping force(Ton) | 3.9 | 4.4 | 6.9 | 10 |

| Oil tank capacity(Gallon) | 60 | 80 | 120 | 250 |

| Nunber of heaters(ZONE) | 4 | 4 | 5 | 5 |

| Heating capacity(KW) | 9.5 | 12.5 | 16.8 | 18 |

| Total installed power(KW) | 22 | 28 | 37 | 53 |

| Extruding capacity per hour(kg/hr) | 24 | 36 | 55 | 75 |

| Dry cycle per hour(time/hr) | 1030*2 | 880*2 | 720*2 | 650*2 |

| Product capacity(c.c./L) | 40-500 | 65-1250 | 150-2500 | 500-5000 |

| Product weight(g.) | 5-40 | 10-100 | 20-170 | 40-280 |

| Min./Max. diameter of product(m/m) | 10-75 | 20-100 | 30-140 | 50-280 |

| Extruding mouth outer diameter(m/m) | 56 | 80 | 150 | 200 |

| Mold center distance(m/m) | * | * | * | * |

| Clamping distance(m/m) | 120-320 | 140-410 | 150-540 | 160-670 |

| Length of mold capacity(m/m) | 126-232 | 156-292 | 200-380 | 240-640 |

| Width of mold capacity(m/m) | 250 | 280 | 380 | 420 |

| Machine net weight(kg) | 6400 | 6900 | 7400 | 8300 |

| Machine dimension(m) | 3*1.8*2.5 | 3.2*1.9*2.5 | 3.2*2*2.8 | 4.2*2.1*2.9 |

| MODEL | FS-45 OSDO | FS-55 OSDO | FS-65 OSDO | FS-75 OSDO |

| Material | PE/PP | PE/PP | PE/PP | PE/PP |

| Screw diameter(m/m) | 45 | 55 | 65 | 75 |

| Screw L/D ratio(L/D) | 24/1 | 24/1 | 24/1 | 24/1 |

| Screw R.P.M speed(r.p.m.) | 15-61 | 15-60 | 15-60 | 15-58 |

| Inveter motor(HP) | 10 | 10 | 15 | 30 |

| Oil hydraulic drive motor(HP) | 7.5 | 10 | 10 | 15 |

| Optional air compressor(HP) | 10 | 15 | 15 | 20 |

| Air pressurer(kg/cm2) | 4-6 | 4-6 | 5-7 | 5-7 |

| Clamping force(Ton) | 3.9 | 4.4 | 6.9 | 10 |

| Oil tank capacity(Gallon) | 60 | 80 | 120 | 160 |

| Nunber of heaters(ZONE) | 6 | 7 | 8 | 8 |

| Heating capacity(KW) | 10.25 | 13.6 | 17.5 | 19 |

| Total installed power(KW) | 26 | 30 | 38 | 54 |

| Extruding capacity per hour(kg/hr) | 24 | 36 | 55 | 75 |

| Dry cycle per hour(time/hr) | 1030*2 | 880*2 | 720*2 | 650*2 |

| Product capacity(c.c./L) | 30-200 | 40-500 | 100-1000 | 280-2000 |

| Product weight(g.) | 4-20 | 5-40 | 10-65 | 20-110 |

| Min./Max. diameter of product(m/m) | 10-65 | 20-70 | 30-85 | 40-110 |

| Extruding mouth outer diameter(m/m) | 42 | 50 | 65 | 80 |

| Mold center distance(m/m) | 100 | 120 | 140 | 160 |

| Clamping distance(m/m) | 130-320 | 140-410 | 150-540 | 160-670 |

| Length of mold capacity(m/m) | 126-232 | 156-292 | 200-380 | 243-466 |

| Width of mold capacity(m/m) | 250 | 280 | 380 | 420 |

| Machine net weight(kg) | 6500 | 7000 | 7500 | 8500 |

| Machine dimension(m) | 3*1.8*2.5 | 3.2*2*2.8 | 3.4*3*3 | 4.2*3.1*3.1 |

| MODEL | FS-55 OTDO | FS-65 OTDO | FS-75 OTDO |

| Material | PE/PP | PE/PP | PE/PP |

| Screw diameter(m/m) | 55 | 65 | 75 |

| Screw L/D ratio(L/D) | 24/1 | 24/1 | 24/1 |

| Screw R.P.M speed(r.p.m.) | 15-60 | 15-60 | 15-58 |

| Inveter motor(HP) | 10 | 15 | 30 |

| Oil hydraulic drive motor(HP) | 10 | 10 | 15 |

| Optional air compressor(HP) | 15 | 15 | 20 |

| Air pressurer(kg/cm2) | 4-6 | 5-7 | 5-7 |

| Clamping force(Ton) | 4.4 | 5.7 | 5.7 |

| Oil tank capacity(Gallon) | 80 | 120 | 160 |

| Nunber of heaters(ZONE) | 9 | 10 | 10 |

| Heating capacity(KW) | 15 | 19.3 | 21.5 |

| Total installed power(KW) | 32 | 40 | 56.5 |

| Extruding capacity per hour(kg/hr) | 36 | 55 | 75 |

| Dry cycle per hour(time/hr) | 850*2 | 720*2 | 650*2 |

| Product capacity(c.c./L) | 15-300 | 50-600 | 100-1000 |

| Product weight(g.) | 5-25 | 8-45 | 10-70 |

| Min./Max. diameter of product(m/m) | 10-55 | 20-70 | 30-90 |

| Extruding mouth outer diameter(m/m) | 40 | 55 | 80 |

| Mold center distance(m/m) | 85+85 | 100+100 | 120+120 |

| Clamping distance(m/m) | 140-410 | 150-540 | 160-670 |

| Length of mold capacity(m/m) | 156-292 | 200-380 | 243-466 |

| Width of mold capacity(m/m) | 300 | 380 | 420 |

| Machine net weight(kg) | 7100 | 7600 | 8700 |

| Machine dimension(m) | 3.4*2*2.8 | 3.6*3*3 | 4.4*3.1*3.1 |

| MODEL | FS-55 OFDO | FS-65 OFDO | FS-75 OFDO |

| Material | PE/PP | PE/PP | PE/PP |

| Screw diameter(m/m) | 55 | 65 | 75 |

| Screw L/D ratio(L/D) | 24/1 | 24/1 | 24/1 |

| Screw R.P.M speed(r.p.m.) | 15-60 | 15-60 | 15-58 |

| Inveter motor(HP) | 15 | 20 | 30 |

| Oil hydraulic drive motor(HP) | 10 | 10 | 15 |

| Optional air compressor(HP) | 15 | 15 | 20 |

| Air pressurer(kg/cm2) | 6-8 | 6-8 | 6-8 |

| Clamping force(Ton) | 4.4 | 6.9 | 13 |

| Oil tank capacity(Gallon) | 80 | 120 | 160 |

| Nunber of heaters(ZONE) | 11 | 13 | 13 |

| Heating capacity(KW) | 16.5 | 20.8 | 25.7 |

| Total installed power(KW) | 37.5 | 48 | 61 |

| Extruding capacity per hour(kg/hr) | 36 | 55 | 75 |

| Dry cycle per hour(time/hr) | 750*2 | 750*2 | 650*2 |

| Product capacity(c.c./L) | 50-250 | 100-400 | 200-600 |

| Product weight(g.) | 5-20 | 10-30 | 20-50 |

| Min./Max. diameter of product(m/m) | 20-55 | 20-55 | 20-70 |

| Extruding mouth outer diameter(m/m) | 37 | 42 | 50 |

| Mold center distance(m/m) | 85+85 | 85+85 | 120+120 |

| Clamping distance(m/m) | 140-410 | 150-410 | 160-670 |

| Length of mold capacity(m/m) | 156-292 | 200-380 | 243-466 |

| Width of mold capacity(m/m) | 410 | 460 | 520 |

| Machine net weight(kg) | 7200 | 7700 | 8900 |

| Machine dimension(m) | 3.4*2*3 | 3.6*3.2*3.2 | 4.4*3.3*3.3 |

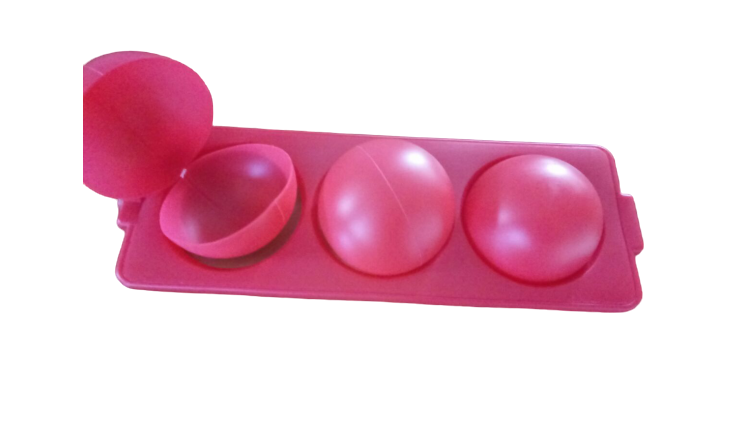

Sample bottles

Sample bottles

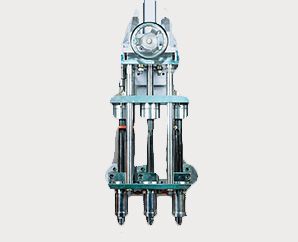

Blowing System

Brake System

Single die head with single station machine

Carriage movement by tie bars with hydraulic system to move as V-type oblique movement.

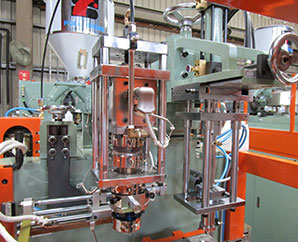

Top view side of FS-45OSSO, 45mm screw, automatic blow molding machine

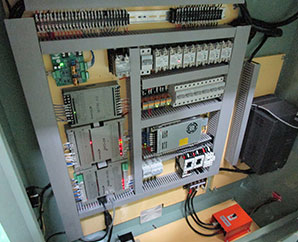

Photo of PLC control panel

Machine outlooking, motor with hopper

Machine outlooking, motor with hopper, with belt type design

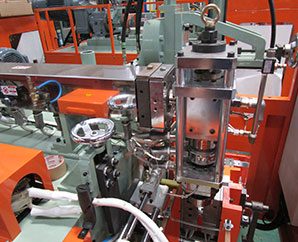

Inside photo of FS-75OFDO automatic blow molding machine, 75mm screw, Four die head with double station blow molding machine

Photo of machine side view

Photo of PLC control panel

Inside photo of die head with blow pin unit, Single die head with signle station blow molding machine

Barrel and screw set with fans

Photo of PLC control panel

Application

Hand washing bottle / cleaning supplies

Blow Molding Plastic Bottles

Oil bottle / oil barrel

Mask/Closed Wound Drainage Systems

Household/Cosmetics

Household/Cleaning product bottle

Household/Cosmetics

Outdoor supplies/Bird balls

Household/Cosmetics

Closed Wound Drainage Systems

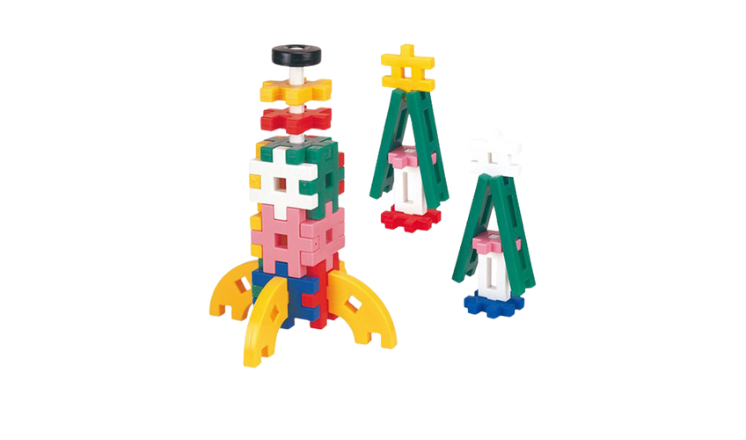

Toys

Household/Cleaning product bottle

Automotive

Household/Cosmetics

Pesticide bottle

Mascara bottle