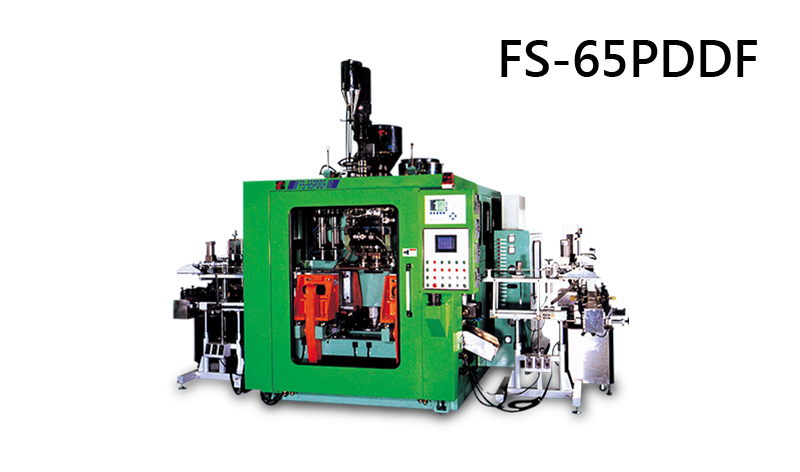

Automatic CO-Extrusion Blow Molding machine P Series

Descripton

-

CO-EXTRUSION BLOW MOLDING MACHINE FOR MULTI-LAYER BOTTLES – Applicable for single and double station with single to multiple die heads for producing up to SIX-LAYER CONTAINERS (2 TO 6-LAYER CO-EXTRUSION), such as chemical bottles, catchup bottles, or cosmetic bottles.

-

Co-extrusion application allows unrelated materials with different characteristics to be combined in one parison through Full Shine special-designed die head. This combination binds different materials, such as combining high-gloss outside layer and barrier layer by an adhesive layer between them in order to achieve the perfect outcome.

-

Co-extrusion application is the advanced technology by the leading brand: Full Shine.

- Machine Model

- Two-layer/Single Die-head/Single Station & Two Color /Single Head & Station

- PHOTOS

- Video

-

Machine Model

|

|

|

EXPOSITION OF FULL SHINE'S MACHINE MODEL

|

|

|

SCREW DIAMETER(M/M)

|

MACHINE SERIES

|

MOLD HEAD(DIE HEAD)

|

MOLD STATION

|

PRODUCT TYPE

|

|

FS-

|

40

|

(H) Horizontal

|

(S) Single Mold Head

|

(S) Single Mold Station

|

(O) Original

|

|

45

|

(P) Parallel

|

(D) Double Mold Heads

|

(D) Double Mold Stations

|

(C) Two Colors

|

|

55

|

(O) Standard / Oblique

|

(T) Three Mold Heads

|

|

(D) Two Layers

|

|

65

|

(A) Pneumatic

|

(F) Four Mold Heads

|

|

(T) Three Layers

|

|

75

|

(L) Frontal

|

(E) Eight Mold Heads

|

|

(F) Four Layers

|

|

80

|

(I) Lateral

|

|

|

(L) Six Layers

|

|

90

|

|

|

|

(V) View Stripe

|

|

100

|

|

|

|

(P) PC baby bottle

|

|

Example

|

|

FS-

|

65

|

P

|

D

|

S

|

D

|

|

Model

|

FS-40 PSSD

|

FS-45 PSSD

|

FS-55 PSSD

|

FS-65 PSSD

|

FS-75 PSSD

|

FS-55 PSSC

|

FS-65 PSSC

|

FS-75 PSSC

|

|

TYPE

|

Two-layer /Single Die-head /Single Station

|

Two Color /Single Head & Station

|

|

1

|

Material

|

|

PE

|

PE

|

PE

|

PE

|

PE

|

PE

|

PE

|

PE

|

|

2

|

Screw diameter

|

m/m

|

40/25

|

45/25

|

55/25

|

65/25

|

75/25

|

55/55

|

65/65

|

75/75

|

|

3

|

Screw L/D ratio

|

L/D

|

24/1

|

24/1

|

24/1

|

24/1

|

24/1

|

24/1

|

24/1

|

24/1

|

|

4

|

Screw R.P.M. speed

|

r.p.m.

|

20-66

|

15-61

|

15-60

|

15-60

|

15-58

|

15-60

|

15-60

|

15-58

|

|

5

|

Inverter motor

|

HP

|

5/2

|

7.5/2

|

10/2

|

15/2

|

25/2

|

10/10

|

15/15

|

25/25

|

|

6

|

Oil hydraulic drive motor

|

HP

|

5

|

7.5

|

10

|

10

|

15

|

10

|

10

|

15

|

|

7

|

Optional air compressor

|

HP

|

5

|

5

|

7.5

|

7.5

|

10

|

7.5

|

7.5

|

10

|

|

8

|

Air pressure

|

Kg/cm2

|

4-6

|

4-6

|

5-7

|

5-7

|

5-7

|

5-7

|

5-7

|

5-7

|

|

9

|

Clamping force

|

Ton

|

2.8

|

3.9

|

4.4

|

6.9

|

10

|

4.4

|

6.9

|

10

|

|

10

|

Oil tank capacity

|

Gallon

|

38

|

55

|

60

|

80

|

120

|

60

|

80

|

120

|

|

11

|

Number of heaters

|

ZONE

|

6

|

6

|

6

|

7

|

7

|

6

|

6

|

7

|

|

12

|

Heating capacity

|

KW

|

9.5

|

12

|

15

|

19.5

|

22

|

19

|

24.5

|

26

|

|

13

|

Total installed power

|

KW

|

19

|

25

|

32

|

40.5

|

44

|

43

|

56

|

77

|

|

14

|

Extruding capacity per hour

|

Kg/hr

|

15

|

24

|

42

|

55

|

75

|

42

|

55

|

75

|

|

15

|

Dry cycle per hour

|

time/hr

|

1285

|

1030

|

880

|

720

|

650

|

880

|

720

|

600

|

|

16

|

Product capacity

|

c.c./L

|

15-500

|

60-1000

|

150-2500

|

1L-5L

|

1L-10L

|

150-2500

|

1L-5L

|

1L-10L

|

|

17

|

Product weight

|

g.

|

5-40

|

10-100

|

20-170

|

40-280

|

80-500

|

20-170

|

40-280

|

80-500

|

|

18

|

Min./Max. diameter of product

|

m/m

|

10-75

|

20-100

|

30-140

|

50-200

|

80-260

|

30-140

|

50-200

|

80-260

|

|

19

|

Extruding mouth outer diameter

|

m/m

|

50

|

56

|

80

|

150

|

200

|

80

|

150

|

200

|

|

20

|

Mold center distance

|

m/m

|

*

|

*

|

*

|

*

|

*

|

*

|

*

|

*

|

|

21

|

Clamping distance

|

m/m

|

50-320

|

50-410

|

140-540

|

160-670

|

50-410

|

140-540

|

160-670

|

160-670

|

|

22

|

Length of mold capacity

|

m/m

|

146-266

|

155-290

|

160-380

|

223-426

|

155-290

|

160-380

|

223-426

|

240-460

|

|

23

|

Width of mold capacity

|

m/m

|

300

|

320

|

360

|

430

|

320

|

360

|

430

|

430

|

|

24

|

Machine net weight

|

Kg

|

3300

|

3800

|

4700

|

7600

|

3800

|

4700

|

7600

|

7300

|

|

25

|

Machine dimension

|

m

|

2.6*1.85*2.7

|

3*1.9*2.8

|

3.1*2*2.8

|

3.6*1.6*3.1

|

4.2*1.7*3.2

|

3.1*2*2.8

|

3.6*1.6*3.1

|

4.2*1.7*3.2

|

الوضعية

Mask/Closed Wound Drainage Systems

Household/Cleaning product bottle

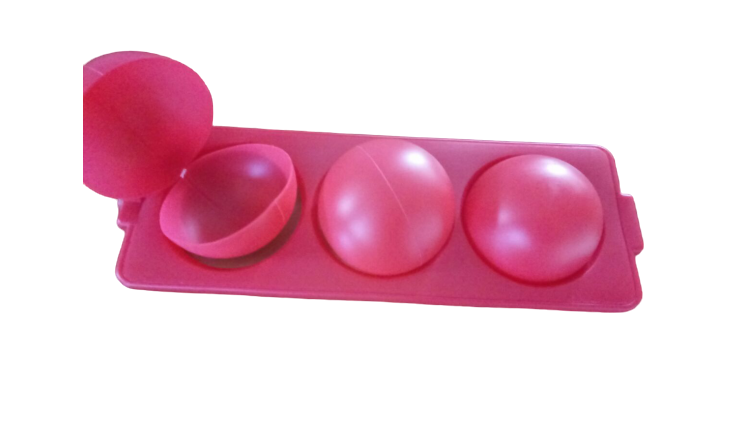

Outdoor supplies/Bird balls

Closed Wound Drainage Systems

Household/Cleaning product bottle

20L Bucket (20L Jerry can)