ماكينة التشكيل(الصبّ) بواسطة النفخ الأوتوماتيكية مجموعة P

الوصف والتفصيل

-

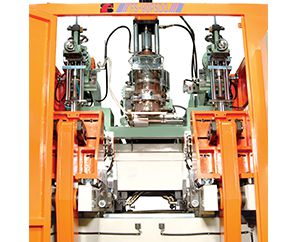

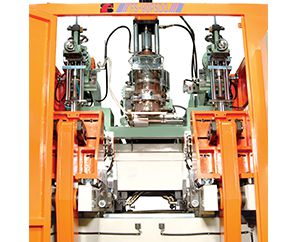

استخدام أذرع منحنية لقوّة شدّ القالب، مزوّدة شريحة توجيه خطّية، صنع في ألمانيا للحركة السريعة.

- ÖZELLIKLER

- Machine Model

- Single Die-head/Single Station

- Double Die-head/Single Station

- Three Die-head/Single Station

- Four Die-head/Single Station

- Single Die-head/Double Station

- Double Die-head/Double Station

- Three Die-head/Double Station

- Single Die-head Single Station Viewstripe

- Double Die-head Single Station Viewstripe

- الصور

- Video

-

ÖZELLIKLER

-

PE, PP, PVC, PC, PETG, PS, PA, TPR, PC, EVA, PBT, Acryl, K-resin, PU, ve benzeri hammaddelerin işlenmesi için uygundur.

-

Opsiyonel HMI dokunmatik ekran.

-

PLC‘li elektrik kontrol sistemi.

-

Kalıp taşıyıcı kızaklar lineer kılavuzlarla donatılmıştır.

-

Alman malı Lineer kızaklar.

-

Opsiyonel programlı cidar kalınlığı için parison komtrollu teçhizat.

-

İşlenmiş ve erimiş hammadde için yüksek verimli vida.

-

Kovan ve vida özel olarak ısıl işlem yapılmıştır.

-

Full shine tarafından özel olarak dizayn edilenözel soğutma tertibatlı iğne gurubu.

-

Mükemmel şişe boynu için özel fonksiyon.

-

Vida dönüşü Alman malı dişli kutusuna direk bağlı Japon malı inverter sürücü ile kontrol edilmektedir.

-

Değişik ürünlerdeki üretim hızını ayarlamak için inverterle control edilebilen küçük bir hız ayarlama düğmesi ile vida hızı ayarlanabilmektedir.

-

Stabil ve hızlı hareket manevraları için özel frenleme sistemleri.

-

Başlığın kaldırma mekanizması hızlı bir extrüzyon sağlar.

-

Şişirme ünitesinin pozisyonu ayarlanabilmektedir ve kalıp değişimi sırasında hidrolik motor adaptesi ile kolaylık sağlar. Bu Full shine tarafından geliştirilen innovative bir çözümdür.

-

Paralel kızak hareketi makinaya,otomatik çapak almayı,test cihazını ve kalıp içi etiketleme makinasını bağlamaya uygun kılar.

-

Kalıp taşıyıcı hareket aksamlarında otomotik yağlama sistemi aşınmaları önler.

-

Seviye indikatörlü veya uydu çizgisi denilen şişelerin üretimi için uygundur.

-

Tüm metal aksamlar;yüksek frekanslı ısıl işlem,elektro kaplama,kumlama,ve koruyucu ortamda ısıl işlemler yapılarak uzun süreli kullanımları sağlanmıştır.

|

|

|

EXPOSITION OF FULL SHINE'S MACHINE MODEL

|

|

|

SCREW DIAMETER(M/M)

|

MACHINE SERIES

|

MOLD HEAD(DIE HEAD)

|

MOLD STATION

|

PRODUCT TYPE

|

|

FS-

|

40

|

(H) Horizontal

|

(S) Single Mold Head

|

(S) Single Mold Station

|

(O) Original

|

|

45

|

(P) Parallel

|

(D) Double Mold Heads

|

(D) Double Mold Stations

|

(C) Two Colors

|

|

55

|

(O) Standard / Oblique

|

(T) Three Mold Heads

|

|

(D) Two Layers

|

|

65

|

(A) Pneumatic

|

(F) Four Mold Heads

|

|

(T) Three Layers

|

|

75

|

(L) Frontal

|

(E) Eight Mold Heads

|

|

(F) Four Layers

|

|

80

|

(I) Lateral

|

|

|

(L) Six Layers

|

|

90

|

|

|

|

(V) View Stripe

|

|

100

|

|

|

|

(P) PC baby bottle

|

|

Example

|

|

FS-

|

65

|

P

|

D

|

S

|

D

|

|

MODEL

|

FS-40 PSSO

|

FS-45 PSSO

|

FS-55 PSSO

|

FS-65 PSSO

|

FS-75 PSSO

|

FS-90 PSSO

|

|

Material

|

PE/PP

|

PE/PP

|

PE/PP

|

PE/PP

|

PE/PP

|

PE/PP

|

|

Screw diameter(m/m)

|

40

|

45

|

55

|

65

|

75

|

90

|

|

Screw L/D ratio(L/D)

|

24/1

|

24/1

|

24/1

|

24/1

|

24/1

|

28/1

|

|

Screw R.P.M speed(r.p.m.)

|

20-66

|

15-61

|

15-60

|

15-60

|

15-58

|

15-56

|

|

Inveter motor(HP)

|

5

|

7.5

|

10

|

15

|

25

|

40

|

|

Oil hydraulic drive motor(HP)

|

5

|

7.5

|

10

|

10

|

15

|

30

|

|

Optional air compressor(HP)

|

5

|

5

|

7.5

|

7.5

|

10

|

15

|

|

Air pressurer(kg/cm2)

|

4-6

|

4-6

|

4-6

|

5-7

|

5-7

|

6-8

|

|

Clamping force(Ton)

|

2.8

|

3.9

|

4.4

|

6.9

|

10

|

5.2

|

|

Oil tank capacity(Gallon)

|

38

|

55

|

60

|

80

|

120

|

250

|

|

Nunber of heaters(ZONE)

|

4

|

4

|

4

|

5

|

5

|

7

|

|

Heating capacity(KW)

|

7

|

9.5

|

12.5

|

16.8

|

18

|

20.5

|

|

Total installed power(KW)

|

15

|

21

|

30

|

43.5

|

48

|

62

|

|

Extruding capacity per hour(kg/hr)

|

15

|

24

|

36

|

55

|

75

|

100

|

|

Dry cycle per hour(time/hr)

|

1285

|

1030

|

880

|

720

|

650

|

650

|

|

Product capacity(c.c./L)

|

15-500

|

60-1000

|

150-2500

|

500-5000

|

5L-10L

|

10L-20L

|

|

Product weight(g.)

|

5-40

|

10-100

|

20-170

|

40-280

|

200-370

|

500-900

|

|

Min./Max. diameter of product(m/m)

|

10-75

|

20-100

|

30-140

|

50-200

|

80-260

|

150-340

|

|

Extruding mouth outer diameter(m/m)

|

50

|

56

|

80

|

150

|

200

|

280

|

|

Mold center distance(m/m)

|

*

|

*

|

*

|

*

|

*

|

*

|

|

Clamping distance(m/m)

|

120-230

|

130-320

|

140-410

|

150-540

|

160-670

|

160-670

|

|

Length of mold capacity(m/m)

|

100-210

|

146-266

|

155-590

|

160-380

|

223-426

|

288-556

|

|

Width of mold capacity(m/m)

|

200

|

300

|

320

|

430

|

480

|

560

|

|

Machine net weight(kg)

|

2500

|

3000

|

3500

|

4400

|

7300

|

8300

|

|

Machine dimension(m)

|

2.3*1.4*2.2

|

3*1.4*2.3

|

3*1.5*2.3

|

3.2*1.6*2.6

|

4.2*1.7*2.7

|

4.1*1.9*3.6

|

|

MODEL

|

FS-40 PDSO

|

FS-45 PDSO

|

FS-55 PDSO

|

FS-65 PDSO

|

FS-75 PDSO

|

FS-90 PDSO

|

|

Material

|

PE/PP

|

PE/PP

|

PE/PP

|

PE/PP

|

PE/PP

|

PE/PP

|

|

Screw diameter(m/m)

|

40

|

45

|

55

|

65

|

75

|

90

|

|

Screw L/D ratio(L/D)

|

24/1

|

24/1

|

24/1

|

24/1

|

24/1

|

28/1

|

|

Screw R.P.M speed(r.p.m.)

|

20-66

|

15-61

|

15-60

|

15-60

|

15-58

|

15-58

|

|

Inveter motor(HP)

|

5

|

7.5

|

10

|

15

|

25

|

60

|

|

Oil hydraulic drive motor(HP)

|

5

|

7.5

|

10

|

10

|

15

|

30

|

|

Optional air compressor(HP)

|

5

|

5

|

7.5

|

7.5

|

10

|

15

|

|

Air pressurer(kg/cm2)

|

4-6

|

4-6

|

5-7

|

5-7

|

5-7

|

6-8

|

|

Clamping force(Ton)

|

2.8

|

3.9

|

4.4

|

6.9

|

10

|

5.2

|

|

Oil tank capacity(Gallon)

|

38

|

55

|

60

|

80

|

120

|

250

|

|

Nunber of heaters(ZONE)

|

6

|

6

|

7

|

8

|

8

|

11

|

|

Heating capacity(KW)

|

7

|

10.25

|

13.6

|

17.5

|

19

|

33

|

|

Total installed power(KW)

|

15.5

|

22

|

29.5

|

37

|

50

|

67

|

|

Extruding capacity per hour(kg/hr)

|

15

|

24

|

36

|

55

|

75

|

100

|

|

Dry cycle per hour(time/hr)

|

1285

|

1030

|

880

|

720

|

650

|

650

|

|

Product capacity(c.c./L)

|

15-200

|

50-500

|

100-1250

|

280-1800

|

0.5L-2.5L

|

1L-5L

|

|

Product weight(g.)

|

4-25

|

5-40

|

10-100

|

20-170

|

40-170

|

80-280

|

|

Min./Max. diameter of product(m/m)

|

10-65

|

20-70

|

30-85

|

40-100

|

40-130

|

100-160

|

|

Extruding mouth outer diameter(m/m)

|

38

|

42

|

50

|

65

|

80

|

150

|

|

Mold center distance(m/m)

|

85

|

100

|

120

|

140

|

160

|

180

|

|

Clamping distance(m/m)

|

120-230

|

130-320

|

140-410

|

150-540

|

160-670

|

160-670

|

|

Length of mold capacity(m/m)

|

100-210

|

146-266

|

155-590

|

160-380

|

223-426

|

288-556

|

|

Width of mold capacity(m/m)

|

200

|

300

|

320

|

430

|

480

|

560

|

|

Machine net weight(kg)

|

2600

|

3200

|

3700

|

4600

|

7500

|

8500

|

|

Machine dimension(m)

|

2.3*1.4*2.2

|

3*1.4*2.3

|

3*1.5*2.3

|

3.2*1.6*2.6

|

4.2*1.7*2.7

|

5.2*1.9*3.5

|

|

MODEL

|

FS-40 PTSO

|

FS-45 PTSO

|

FS-55 PTSO

|

FS-65 PTSO

|

FS-75 PTSO

|

FS-90 PTSO

|

|

Material

|

PE/PP

|

PE/PP

|

PE/PP

|

PE/PP

|

PE/PP

|

PE/PP

|

|

Screw diameter(m/m)

|

40

|

45

|

55

|

65

|

75

|

90

|

|

Screw L/D ratio(L/D)

|

24/1

|

24/1

|

24/1

|

24/1

|

24/1

|

28/1

|

|

Screw R.P.M speed(r.p.m.)

|

20-66

|

15-61

|

15-60

|

15-60

|

15-58

|

15-58

|

|

Inveter motor(HP)

|

5

|

7.5

|

10

|

15

|

25

|

60

|

|

Oil hydraulic drive motor(HP)

|

5

|

7.5

|

10

|

10

|

15

|

30

|

|

Optional air compressor(HP)

|

7.5

|

7.5

|

10

|

10

|

15

|

20

|

|

Air pressurer(kg/cm2)

|

4-6

|

4-6

|

5-7

|

5-7

|

5-7

|

6-8

|

|

Clamping force(Ton)

|

2.8

|

3.9

|

4.4

|

6.9

|

10

|

5.2

|

|

Oil tank capacity(Gallon)

|

38

|

55

|

60

|

80

|

120

|

250

|

|

Nunber of heaters(ZONE)

|

8

|

8

|

9

|

10

|

10

|

11

|

|

Heating capacity(KW)

|

8.5

|

12

|

15

|

19.3

|

21.5

|

42.8

|

|

Total installed power(KW)

|

16.5

|

23.5

|

32

|

39

|

52.5

|

88

|

|

Extruding capacity per hour(kg/hr)

|

15

|

24

|

36

|

55

|

75

|

100

|

|

Dry cycle per hour(time/hr)

|

1250

|

1000

|

850

|

720

|

650

|

650

|

|

Product capacity(c.c./L)

|

10-125

|

20-325

|

40-825

|

100-1000

|

180-1500

|

1L-3L

|

|

Product weight(g.)

|

3-10

|

5-25

|

10-50

|

10-90

|

15-145

|

80-200

|

|

Min./Max. diameter of product(m/m)

|

10-45

|

20-55

|

30-55

|

30-80

|

30-95

|

60-110

|

|

Extruding mouth outer diameter(m/m)

|

30

|

37

|

40

|

55

|

80

|

98

|

|

Mold center distance(m/m)

|

75+75

|

85+85

|

100+100

|

120+120

|

120+120

|

180+180

|

|

Clamping distance(m/m)

|

120-230

|

130-320

|

140-410

|

150-540

|

160-670

|

160-670

|

|

Length of mold capacity(m/m)

|

100-210

|

146-266

|

155-590

|

160-380

|

223-426

|

288-556

|

|

Width of mold capacity(m/m)

|

200

|

300

|

320

|

430

|

480

|

560

|

|

Machine net weight(kg)

|

2800

|

3400

|

3900

|

4900

|

7900

|

8900

|

|

Machine dimension(m)

|

2.3*1.4*2.2

|

3*1.4*2.3

|

3*1.5*2.3

|

3.2*1.6*2.6

|

4.2*1.7*2.7

|

5.2*1.9*3.5

|

|

MODEL

|

FS-55 PFSO

|

FS-65 PFSO

|

FS-75 PFSO

|

FS-90 PFSO

|

|

Material

|

PE/PP

|

PE/PP

|

PE/PP

|

PE/PP

|

|

Screw diameter(m/m)

|

55

|

65

|

75

|

90

|

|

Screw L/D ratio(L/D)

|

24/1

|

24/1

|

24/1

|

28/1

|

|

Screw R.P.M speed(r.p.m.)

|

15-60

|

15-60

|

15-58

|

15-58

|

|

Inveter motor(HP)

|

15

|

20

|

30

|

60

|

|

Oil hydraulic drive motor(HP)

|

10

|

15

|

15

|

30

|

|

Optional air compressor(HP)

|

15

|

15

|

20

|

20

|

|

Air pressurer(kg/cm2)

|

6-8

|

6-8

|

6-8

|

6-8

|

|

Clamping force(Ton)

|

4.4

|

6.9

|

10

|

5.2

|

|

Oil tank capacity(Gallon)

|

60

|

80

|

120

|

250

|

|

Nunber of heaters(ZONE)

|

11

|

13

|

13

|

11

|

|

Heating capacity(KW)

|

16.5

|

20.8

|

25.7

|

42.8

|

|

Total installed power(KW)

|

37.5

|

48

|

61

|

88

|

|

Extruding capacity per hour(kg/hr)

|

36

|

55

|

75

|

100

|

|

Dry cycle per hour(time/hr)

|

750

|

750

|

650

|

650

|

|

Product capacity(c.c./L)

|

30-200

|

100-500

|

300-1000

|

500-2500

|

|

Product weight(g.)

|

10-25

|

10-40

|

15-90

|

40-170

|

|

Min./Max. diameter of product(m/m)

|

20-55

|

30-55

|

30-90

|

30-90

|

|

Extruding mouth outer diameter(m/m)

|

37

|

42

|

50

|

75

|

|

Mold center distance(m/m)

|

85+85+85

|

85+85+85

|

180+180+180

|

180+180+180

|

|

Clamping distance(m/m)

|

140-410

|

150-540

|

160-670

|

160-670

|

|

Length of mold capacity(m/m)

|

155-290

|

160-380

|

243-466

|

288-556

|

|

Width of mold capacity(m/m)

|

430

|

480

|

520

|

560

|

|

Machine net weight(kg)

|

4100

|

5200

|

8300

|

9300

|

|

Machine dimension(m)

|

3.1*1.8*2.3

|

3.2*1.9*2.6

|

4.3*2*2.7

|

5.2*3.1*3.5

|

|

MODEL

|

FS-45 PSDO

|

FS-55 PSDO

|

FS-65 PSDO

|

FS-75 PSDO

|

FS-90 PSDO

|

FS-100 PSDO

|

|

Material

|

PE/PP

|

PE/PP

|

PE/PP

|

PE/PP

|

PE/PP

|

PE/PP

|

|

Screw diameter(m/m)

|

45

|

55

|

65

|

75

|

90

|

100

|

|

Screw L/D ratio(L/D)

|

24/1

|

24/1

|

24/1

|

24/1

|

28/1

|

28/1

|

|

Screw R.P.M speed(r.p.m.)

|

15-62

|

15-60

|

15-60

|

15-58

|

15-56

|

20-65

|

|

Inveter motor(HP)

|

7.5

|

10

|

15

|

30

|

75

|

75

|

|

Oil hydraulic drive motor(HP)

|

7.5

|

10

|

10

|

15

|

30

|

40

|

|

Optional air compressor(HP)

|

10

|

15

|

15

|

20

|

30

|

30

|

|

Air pressurer(kg/cm2)

|

4-6

|

4-6

|

5-7

|

5-7

|

6-8

|

6-8

|

|

Clamping force(Ton)

|

3.9

|

4.4

|

6.9

|

10

|

5.2

|

6.5

|

|

Oil tank capacity(Gallon)

|

60

|

80

|

120

|

160

|

250

|

300

|

|

Nunber of heaters(ZONE)

|

4

|

4

|

5

|

5

|

11

|

8

|

|

Heating capacity(KW)

|

9.5

|

12.5

|

16.8

|

18

|

20.5

|

36

|

|

Total installed power(KW)

|

22

|

28

|

37

|

53

|

63

|

114

|

|

Extruding capacity per hour(kg/hr)

|

24

|

36

|

55

|

75

|

100

|

180

|

|

Dry cycle per hour(time/hr)

|

1030*2

|

800*2

|

720*2

|

650*2

|

650*2

|

480*2

|

|

Product capacity(c.c./L)

|

40-500

|

65-1250

|

150-2500

|

500-5000

|

5L-10L

|

10L-20L

|

|

Product weight(g.)

|

5-40

|

10-100

|

20-170

|

40-280

|

200-370

|

500-900

|

|

Min./Max. diameter of product(m/m)

|

10-75

|

20-100

|

30-140

|

50-200

|

100-280

|

200-300

|

|

Extruding mouth outer diameter(m/m)

|

56

|

80

|

150

|

200

|

280

|

420

|

|

Mold center distance(m/m)

|

*

|

*

|

*

|

*

|

*

|

*

|

|

Clamping distance(m/m)

|

130-320

|

140-410

|

150-540

|

160-670

|

160-670

|

390-750

|

|

Length of mold capacity(m/m)

|

146-266

|

155-290

|

160-380

|

223-426

|

288-556

|

386-640

|

|

Width of mold capacity(m/m)

|

300

|

320

|

360

|

430

|

520

|

560

|

|

Machine net weight(kg)

|

7000

|

7400

|

7900

|

8500

|

9700

|

11500

|

|

Machine dimension(m)

|

3*1.8*2.5

|

3*1.9*2.5

|

3.2*2*2.8

|

4.2*2.1*2.9

|

5.2*2.3*3.7

|

5.8*3.3*4

|

|

MODEL

|

FS-45 PDDO

|

FS-55 PDDO

|

FS-65 PDDO

|

FS-75 PDDO

|

FS-90 PDDO

|

FS-100 PDDO

|

|

Material

|

PE/PP

|

PE/PP

|

PE/PP

|

PE/PP

|

PE/PP

|

PE/PP

|

|

Screw diameter(m/m)

|

45

|

55

|

65

|

75

|

90

|

100

|

|

Screw L/D ratio(L/D)

|

24/1

|

24/1

|

24/1

|

24/1

|

28/1

|

28/1

|

|

Screw R.P.M speed(r.p.m.)

|

15-61

|

15-60

|

15-60

|

15-58

|

15-56

|

20-65

|

|

Inveter motor(HP)

|

10

|

10

|

15

|

30

|

40

|

75

|

|

Oil hydraulic drive motor(HP)

|

7.5

|

10

|

10

|

15

|

15

|

25

|

|

Optional air compressor(HP)

|

10

|

15

|

15

|

20

|

30

|

30

|

|

Air pressurer(kg/cm2)

|

4-6

|

4-6

|

5-7

|

5-7

|

6-8

|

6-8

|

|

Clamping force(Ton)

|

1.5

|

4.4

|

6.9

|

10

|

13

|

26

|

|

Oil tank capacity(Gallon)

|

60

|

80

|

120

|

160

|

250

|

300

|

|

Nunber of heaters(ZONE)

|

8

|

7

|

8

|

8

|

10

|

10

|

|

Heating capacity(KW)

|

10

|

13.6

|

17.5

|

19

|

22

|

37

|

|

Total installed power(KW)

|

21.5

|

30

|

38

|

54

|

65

|

113

|

|

Extruding capacity per hour(kg/hr)

|

32

|

36

|

55

|

75

|

100

|

180

|

|

Dry cycle per hour(time/hr)

|

1030*2

|

800*2

|

720*2

|

650*2

|

650*2

|

480*2

|

|

Product capacity(c.c./L)

|

30-200

|

40-500

|

100-1000

|

280-2000

|

700-3000

|

2L-6L

|

|

Product weight(g.)

|

4-20

|

5-40

|

10-65

|

20-110

|

40-180

|

110-300

|

|

Min./Max. diameter of product(m/m)

|

10-65

|

20-70

|

30-85

|

40-110

|

50-150

|

100-220

|

|

Extruding mouth outer diameter(m/m)

|

42

|

50

|

65

|

80

|

150

|

200

|

|

Mold center distance(m/m)

|

85

|

120

|

140

|

160

|

220

|

250

|

|

Clamping distance(m/m)

|

130-320

|

140-410

|

150-540

|

160-670

|

160-670

|

390-750

|

|

Length of mold capacity(m/m)

|

146-370

|

155-290

|

160-380

|

223-426

|

288-556

|

385-640

|

|

Width of mold capacity(m/m)

|

300

|

320

|

360

|

430

|

520

|

560

|

|

Machine net weight(kg)

|

7200

|

7600

|

8200

|

9100

|

10100

|

11900

|

|

Machine dimension(m)

|

3*1.4*2.3

|

3.2*2*2.8

|

3.4*3*3

|

4.4*3.1*3.1

|

5.4*3.3*3.9

|

6.4*3.5*5.6

|

|

MODEL

|

FS-55 PTDO

|

FS-65 PTDO

|

FS-75 PTDO

|

FS-90 PTDO

|

|

Material

|

PE/PP

|

PE/PP

|

PE/PP

|

PE/PP

|

|

Screw diameter(m/m)

|

55

|

65

|

75

|

90

|

|

Screw L/D ratio(L/D)

|

24/1

|

24/1

|

24/1

|

28/1

|

|

Screw R.P.M speed(r.p.m.)

|

15-60

|

15-60

|

15-58

|

15-58

|

|

Inveter motor(HP)

|

10

|

15

|

30

|

40

|

|

Oil hydraulic drive motor(HP)

|

10

|

10

|

15

|

15

|

|

Optional air compressor(HP)

|

15

|

15

|

20

|

20

|

|

Air pressurer(kg/cm2)

|

4-6

|

5-7

|

5-7

|

6-8

|

|

Clamping force(Ton)

|

4.4

|

6.9

|

10

|

13

|

|

Oil tank capacity(Gallon)

|

80

|

120

|

160

|

250

|

|

Nunber of heaters(ZONE)

|

9

|

10

|

10

|

12

|

|

Heating capacity(KW)

|

15

|

19.3

|

21.5

|

25

|

|

Total installed power(KW)

|

32

|

40

|

56.5

|

68

|

|

Extruding capacity per hour(kg/hr)

|

36

|

55

|

75

|

100

|

|

Dry cycle per hour(time/hr)

|

850*2

|

720*2

|

650*2

|

650*2

|

|

Product capacity(c.c./L)

|

15-300

|

50-600

|

100-1000

|

280-2000

|

|

Product weight(g.)

|

5-25

|

8-45

|

10-70

|

20-110

|

|

Min./Max. diameter of product(m/m)

|

10-55

|

20-70

|

30-90

|

40-90

|

|

Extruding mouth outer diameter(m/m)

|

40

|

55

|

80

|

98

|

|

Mold center distance(m/m)

|

85+85

|

100+100

|

120+120

|

120+120

|

|

Clamping distance(m/m)

|

140-410

|

150-540

|

160-670

|

160-670

|

|

Length of mold capacity(m/m)

|

155-290

|

160-380

|

233-426

|

288-556

|

|

Width of mold capacity(m/m)

|

320

|

360

|

430

|

520

|

|

Machine net weight(kg)

|

7800

|

8400

|

9400

|

10500

|

|

Machine dimension(m)

|

3.4*2.1*2.8

|

3.6*3.1*3

|

4.4*3.2*3.1

|

5.4*3.4*3.9

|

|

MODEL

|

FS-45 PSSV

|

FS-55 PSSV

|

FS-65 PSSV

|

FS-75 PSSV

|

FS-90 PSSV

|

|

Material

|

PE/PP

|

PE/PP

|

PE/PP

|

PE/PP

|

PE/PP

|

|

Screw diameter(m/m)

|

45/25

|

55/25

|

65/25

|

75/25

|

90/25

|

|

Screw L/D ratio(L/D)

|

24/1

|

24/1

|

24/1

|

24/1

|

28/1

|

|

Screw R.P.M speed(r.p.m.)

|

15-61/5-25

|

15-60/5-25

|

15-60/5-25

|

15-58/5-25

|

15-56/5-25

|

|

Inveter motor(HP)

|

7.5/2

|

10/2

|

15/2

|

25/2

|

60/2

|

|

Oil hydraulic drive motor(HP)

|

7.5

|

10

|

10

|

15

|

30

|

|

Optional air compressor(HP)

|

5

|

7.5

|

7.5

|

10

|

15

|

|

Air pressurer(kg/cm2)

|

4-6

|

4-6

|

5-7

|

5-7

|

6-8

|

|

Clamping force(Ton)

|

3.9

|

4.4

|

6.9

|

9.5

|

5.2

|

|

Oil tank capacity(Gallon)

|

55

|

60

|

80

|

120

|

250

|

|

Nunber of heaters(ZONE)

|

6

|

6

|

7

|

7

|

11

|

|

Heating capacity(KW)

|

11.5

|

14.5

|

18.8

|

23

|

40

|

|

Total installed power(KW)

|

24.5

|

31.5

|

40.5

|

54.5

|

72.5

|

|

Extruding capacity per hour(kg/hr)

|

30

|

42

|

61

|

81

|

106

|

|

Dry cycle per hour(time/hr)

|

1030

|

880

|

720

|

650

|

65

|

|

Product capacity(c.c./L)

|

60-1000

|

150-2500

|

500-5000

|

5L-10L

|

10L-20L

|

|

Product weight(g.)

|

10-100

|

20-170

|

40-280

|

200-370

|

500-900

|

|

Min./Max. diameter of product(m/m)

|

20-100

|

30-140

|

50-200

|

80-260

|

50-340

|

|

Extruding mouth outer diameter(m/m)

|

56

|

80

|

150

|

200

|

280

|

|

Mold center distance(m/m)

|

*

|

*

|

*

|

*

|

*

|

|

Clamping distance(m/m)

|

130-320

|

140-410

|

150-540

|

160-670

|

160-670

|

|

Length of mold capacity(m/m)

|

146-266

|

155-290

|

160-380

|

223-426

|

288-556

|

|

Width of mold capacity(m/m)

|

300

|

320

|

430

|

480

|

600

|

|

Machine net weight(kg)

|

3600

|

3800

|

4700

|

7600

|

8600

|

|

Machine dimension(m)

|

3*1.4*2.9

|

3*1.5*2.9

|

3.6*1.6*3.2

|

4.2*1.7*3.3

|

5.38*2.45*3.43

|

|

MODEL

|

FS-45 PDSV

|

FS-55 PDSV

|

FS-65 PDSV

|

FS-75 PDSV

|

FS-90 PDSV

|

|

Material

|

PE/PP

|

PE/PP

|

PE/PP

|

PE/PP

|

PE/PP

|

|

Screw diameter(m/m)

|

45/25

|

55/25

|

65/25

|

75/25

|

90/25

|

|

Screw L/D ratio(L/D)

|

24/1

|

24/1

|

24/1

|

24/1

|

28/1

|

|

Screw R.P.M speed(r.p.m.)

|

15-61/5-25

|

15-60/5-25

|

15-60/5-25

|

15-58/5-25

|

15-58/5-25

|

|

Inveter motor(HP)

|

7.5/2

|

10/2

|

15/2

|

25/2

|

40/2

|

|

Oil hydraulic drive motor(HP)

|

7.5

|

10

|

10

|

15

|

15

|

|

Optional air compressor(HP)

|

5

|

7.5

|

7.5

|

10

|

15

|

|

Air pressurer(kg/cm2)

|

4-6

|

5-7

|

5-7

|

5-7

|

6-8

|

|

Clamping force(Ton)

|

3.9

|

4.4

|

6.9

|

9.5

|

13

|

|

Oil tank capacity(Gallon)

|

55

|

60

|

80

|

120

|

250

|

|

Nunber of heaters(ZONE)

|

8

|

10

|

10

|

10

|

12

|

|

Heating capacity(KW)

|

14.5

|

18.8

|

20.3

|

25

|

36

|

|

Total installed power(KW)

|

27.5

|

36.5

|

43

|

57

|

80

|

|

Extruding capacity per hour(kg/hr)

|

30

|

42

|

61

|

81

|

106

|

|

Dry cycle per hour(time/hr)

|

1030

|

880

|

720

|

650

|

650

|

|

Product capacity(c.c./L)

|

40-500

|

100-1250

|

280-1800

|

0.5L-2.5L

|

1L-5L

|

|

Product weight(g.)

|

5-40

|

10-100

|

20-170

|

40-170

|

100-160

|

|

Min./Max. diameter of product(m/m)

|

20-70

|

30-85

|

40-100

|

40-130

|

100-160

|

|

Extruding mouth outer diameter(m/m)

|

42

|

50

|

65

|

80

|

150

|

|

Mold center distance(m/m)

|

100

|

120

|

140

|

160

|

200

|

|

Clamping distance(m/m)

|

130-320

|

140-410

|

150-540

|

160-670

|

160-670

|

|

Length of mold capacity(m/m)

|

146-266

|

155-290

|

160-380

|

223-426

|

288-556

|

|

Width of mold capacity(m/m)

|

300

|

320

|

430

|

480

|

560

|

|

Machine net weight(kg)

|

3700

|

3900

|

4800

|

7700

|

8700

|

|

Machine dimension(m)

|

3*1.6*2.9

|

3*1.7*2.9

|

3.6*1.8*3.2

|

4.2*1.9*3.3

|

5.2*2.1*4.1

|

زجاجات صغيرة

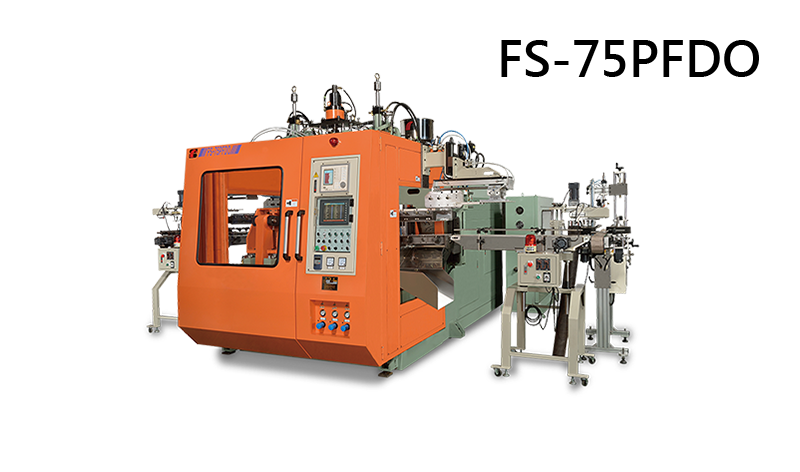

وظيفة التوازي والخطيّة لناقلات القوالب

تصميم أذرع منحنية لشدّ القوالب.

محطّة مزدوجة ( مركز مزدوج)

الوضعية

Hand washing bottle / cleaning supplies

Water bottle or specific container

Mask/Closed Wound Drainage Systems

Household/Cleaning product bottle

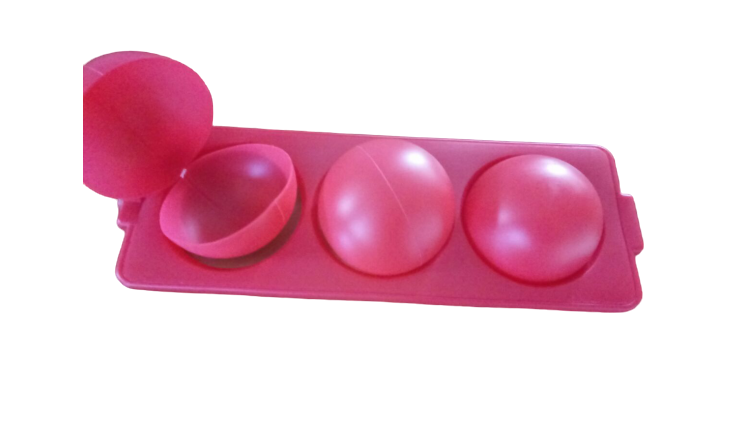

Outdoor supplies/Bird balls

Closed Wound Drainage Systems

Household/Cleaning product bottle

20L Bucket (20L Jerry can)