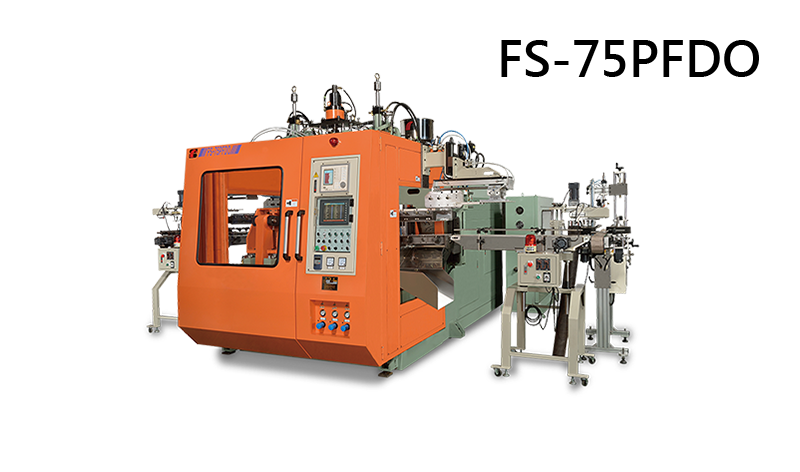

Maquina Sopladora de Botellas Automática P series

DESCRIPCIÓN

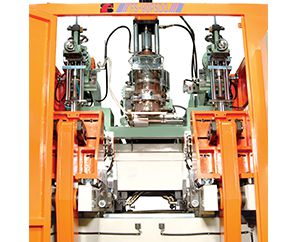

La máquina sopladora automática P series de FULL SHINE es versátil y eficiente para la producción de una variedad de productos plásticos. Puede producir productos con un volumen de 20 ml a 30 L, y está disponible en configuraciones de una estación o de dos estaciones. La máquina es compatible con una variedad de materiales plásticos, incluyendo PE, PP, PETG, PVC, ABS, PA, PS y materiales de coextrusión. La máquina sopladora automática también soporta un sistema híbrido, control de parison, auto desbarbado y soluciones llave en mano. Esto la convierte en una excelente opción para empresas que producen productos de alta calidad con dimensiones precisas y rentabilidad.

-

Capacidad para el procesamiento de materiales diversos, tales como PE, PP, PVC, PP, PETG, PS, PA, TPR, PC, EVA, PBT, acrílico, resina-K, PU.

- CARACTERÍSTICAS

- MÁQUINA MODELO

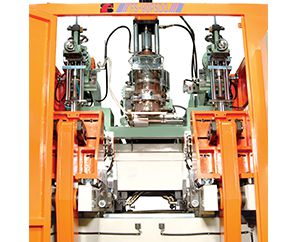

- UNA CABEZA DE MOLDE/UNA ESTACIÓN

- DOS CABEZAS DE MOLDE/UNA ESTACIÓN

- TRES CABEZAS DE MOLDE/UNA ESTACIÓN

- CUATRO CABEZAS DE MOLDE/UNA ESTACIÓN

- UNA CABEZA DE MOLDE/DOS ESTACIONES

- DOS CABEZAS DE MOLDE/DOS ESTACIONES

- TRES CABEZAS DE MOLDE/DOS ESTACIONES

- UNA CABEZA DE MOLDE UNA ESTACIÓN VISTA RAYA

- DOS CABEZAS DE MOLDE UNA ESTACIÓN VISTA RAYA

- FOTOS

- VÍDEO

-

CARACTERÍSTICAS

-

Capacidad para el procesamiento de materiales diversos, tales como PE, PP, PVC, PP, PETG, PS, PA, TPR, PC, EVA, PBT, acrílico, resina-K, PU.

-

HMI pantalla tactil (opcional).

-

Sistema de control electrico con PLC.

-

Manos curvas( Manos de rodilleras) de los moviminetos del molde equipados con transductores lineales.

-

Sensores Lineales , fabricados en Alemania.

-

Capable of equipping parison wall thickness controller/programmer (Option)

-

Alta eficiencia deel tornillo en la zona de mezclado , garantizando un completo proceso de las resinas.

-

Barril y Tornillo tratdos termicamente con nitorgeno. Además, la maquina sopladora de botellas incluye un barril y tornillo tratados térmicamente con nitrógeno para garantizar su durabilidad y eficiencia.

-

Sistema especial de refrigeracion en el tornillo de soplado, disenado especialmente por Full Shine. La maquina sopladora de botellas también cuenta con un sistema especial de refrigeración en el tornillo de soplado, diseñado específicamente por Full Shine.

-

Function de Slight draw-up para un acabado de cuello perfecto.

-

Tornillo montado desde la caja de trasmison hecha en Alemania con inverter de Japon.

-

Velocidad de rotacion del tornillo controlado con inverter, para tener bajas velocidades de rotaciom y poder producir diferentes envases pequenos.

-

Sistema especial de frenado manteniendo la estabilidad en los movimientos.

-

Mecanismo de levantamineto de cabezal para asegurar una rápida extrusión.

-

Unidad de sopaldo que puede ser ajustada en su posición, con motor hidráulico que garantiza un cambio facil de molde. Este es un innovador diseño desarrollado por Full Shine.

-

Movimientos paralelos diseñados para trabajar con rebabador, control de fugas y function de in mold labeling.

-

Equipo d elubricacion para reducirel desgaste en las partes móviles.

-

Diseñada para producir botellas con líneas , llamada mirilla o indicador de nivel.

-

Todos las piezas metalicas estan sometidas a un riguroso proceso de control de calidad, que incluye el tratamiento termico con alta frecuencia. Nitruración, cromado, Galvanoplastia , para garantizar protección contra el desgaste prematuro y la oxidación.

|

|

|

EXPOSICIÓN DEL MODELO DE MÁQUINA DE FULL SHINE

|

|

|

DIÁMETRO DEL TORNILLO (MM)

|

SERIE DE MÁQUINAS

|

CABEZA DE MOLDE (CABEZA DE MATRIZ)

|

ESTACIÓN DE MOLDE

|

TIPO DE PRODUCTO

|

|

FS-

|

40

|

(H) Horizontal

|

(S) Cabeza de Molde Única

|

(S) Estación de Molde Única

|

(O) Original

|

|

45

|

(P) Paralelo

|

(D) Dos Cabezas de Molde

|

(D) Dos Estaciones de Molde

|

(C) Dos Colores

|

|

55

|

(O) Estándar / Oblicuo

|

(T) Tres Cabezas de Molde

|

|

(D) Dos Capas

|

|

65

|

(A) Neumático

|

(F) Cuatro Cabezas de Molde

|

|

(T) Tres Capas

|

|

75

|

(L) Frontal

|

(E) Ocho Cabezas de Molde

|

|

(F) Cuatro Capas

|

|

80

|

(I) Lateral

|

|

|

(L) Seis Capas

|

|

90

|

|

|

|

(V) Vista de Rayas

|

|

100

|

|

|

|

(P) Biberón de PC

|

|

Ejemplo

|

|

FS-

|

65

|

P

|

D

|

S

|

D

|

|

MODEL

|

FS-40 PSSO

|

FS-45 PSSO

|

FS-55 PSSO

|

FS-65 PSSO

|

FS-75 PSSO

|

FS-90 PSSO

|

|

Material

|

PE/PP

|

PE/PP

|

PE/PP

|

PE/PP

|

PE/PP

|

PE/PP

|

|

Screw diameter(m/m)

|

40

|

45

|

55

|

65

|

75

|

90

|

|

Screw L/D ratio(L/D)

|

24/1

|

24/1

|

24/1

|

24/1

|

24/1

|

28/1

|

|

Screw R.P.M speed(r.p.m.)

|

20-66

|

15-61

|

15-60

|

15-60

|

15-58

|

15-56

|

|

Inverter motor(HP)

|

5

|

7.5

|

10

|

15

|

25

|

40

|

|

Oil hydraulic drive motor(HP)

|

5

|

7.5

|

10

|

10

|

15

|

30

|

|

Optional air compressor(HP)

|

5

|

5

|

7.5

|

7.5

|

10

|

15

|

|

Air pressure(kg/cm2)

|

4-6

|

4-6

|

4-6

|

5-7

|

5-7

|

6-8

|

|

Clamping force(Ton)

|

2.8

|

3.9

|

4.4

|

6.9

|

10

|

5.2

|

|

Oil tank capacity(Gallon)

|

38

|

55

|

60

|

80

|

120

|

250

|

|

Number of heaters(ZONE)

|

4

|

4

|

4

|

5

|

5

|

7

|

|

Heating capacity(KW)

|

7

|

9.5

|

12.5

|

16.8

|

18

|

20.5

|

|

Total installed power(KW)

|

15

|

21

|

30

|

43.5

|

48

|

62

|

|

Extruding capacity per hour(kg/hr)

|

15

|

24

|

36

|

55

|

75

|

100

|

|

Dry cycle per hour(time/hr)

|

1285

|

1030

|

880

|

720

|

650

|

650

|

|

Product capacity(c.c./L)

|

15-500

|

60-1000

|

150-2500

|

500-5000

|

5L-10L

|

10L-20L

|

|

Product weight(g.)

|

5-40

|

10-100

|

20-170

|

40-280

|

200-370

|

500-900

|

|

Min./Max. diameter of product(m/m)

|

10-75

|

20-100

|

30-140

|

50-200

|

80-260

|

150-340

|

|

Extruding mouth outer diameter(m/m)

|

50

|

56

|

80

|

150

|

200

|

280

|

|

Mold center distance(m/m)

|

*

|

*

|

*

|

*

|

*

|

*

|

|

Clamping distance(m/m)

|

120-230

|

130-320

|

140-410

|

150-540

|

160-670

|

160-670

|

|

Length of mold capacity(m/m)

|

100-210

|

146-266

|

155-590

|

160-380

|

223-426

|

288-556

|

|

Width of mold capacity(m/m)

|

200

|

300

|

320

|

430

|

480

|

560

|

|

Machine net weight(kg)

|

2500

|

3000

|

3500

|

4400

|

7300

|

8300

|

|

Machine dimension(m)

|

2.3*1.4*2.2

|

3*1.4*2.3

|

3*1.5*2.3

|

3.2*1.6*2.6

|

4.2*1.7*2.7

|

4.1*1.9*3.6

|

|

MODEL

|

FS-40 PDSO

|

FS-45 PDSO

|

FS-55 PDSO

|

FS-65 PDSO

|

FS-75 PDSO

|

FS-90 PDSO

|

|

Material

|

PE/PP

|

PE/PP

|

PE/PP

|

PE/PP

|

PE/PP

|

PE/PP

|

|

Screw diameter(m/m)

|

40

|

45

|

55

|

65

|

75

|

90

|

|

Screw L/D ratio(L/D)

|

24/1

|

24/1

|

24/1

|

24/1

|

24/1

|

28/1

|

|

Screw R.P.M speed(r.p.m.)

|

20-66

|

15-61

|

15-60

|

15-60

|

15-58

|

15-58

|

|

Inveter motor(HP)

|

5

|

7.5

|

10

|

15

|

25

|

60

|

|

Oil hydraulic drive motor(HP)

|

5

|

7.5

|

10

|

10

|

15

|

30

|

|

Optional air compressor(HP)

|

5

|

5

|

7.5

|

7.5

|

10

|

15

|

|

Air pressurer(kg/cm2)

|

4-6

|

4-6

|

5-7

|

5-7

|

5-7

|

6-8

|

|

Clamping force(Ton)

|

2.8

|

3.9

|

4.4

|

6.9

|

10

|

5.2

|

|

Oil tank capacity(Gallon)

|

38

|

55

|

60

|

80

|

120

|

250

|

|

Nunber of heaters(ZONE)

|

6

|

6

|

7

|

8

|

8

|

11

|

|

Heating capacity(KW)

|

7

|

10.25

|

13.6

|

17.5

|

19

|

33

|

|

Total installed power(KW)

|

15.5

|

22

|

29.5

|

37

|

50

|

67

|

|

Extruding capacity per hour(kg/hr)

|

15

|

24

|

36

|

55

|

75

|

100

|

|

Dry cycle per hour(time/hr)

|

1285

|

1030

|

880

|

720

|

650

|

650

|

|

Product capacity(c.c./L)

|

15-200

|

50-500

|

100-1250

|

280-1800

|

0.5L-2.5L

|

1L-5L

|

|

Product weight(g.)

|

4-25

|

5-40

|

10-100

|

20-170

|

40-170

|

80-280

|

|

Min./Max. diameter of product(m/m)

|

10-65

|

20-70

|

30-85

|

40-100

|

40-130

|

100-160

|

|

Extruding mouth outer diameter(m/m)

|

38

|

42

|

50

|

65

|

80

|

150

|

|

Mold center distance(m/m)

|

85

|

100

|

120

|

140

|

160

|

180

|

|

Clamping distance(m/m)

|

120-230

|

130-320

|

140-410

|

150-540

|

160-670

|

160-670

|

|

Length of mold capacity(m/m)

|

100-210

|

146-266

|

155-590

|

160-380

|

223-426

|

288-556

|

|

Width of mold capacity(m/m)

|

200

|

300

|

320

|

430

|

480

|

560

|

|

Machine net weight(kg)

|

2600

|

3200

|

3700

|

4600

|

7500

|

8500

|

|

Machine dimension(m)

|

2.3*1.4*2.2

|

3*1.4*2.3

|

3*1.5*2.3

|

3.2*1.6*2.6

|

4.2*1.7*2.7

|

5.2*1.9*3.5

|

|

MODEL

|

FS-40 PTSO

|

FS-45 PTSO

|

FS-55 PTSO

|

FS-65 PTSO

|

FS-75 PTSO

|

FS-90 PTSO

|

|

Material

|

PE/PP

|

PE/PP

|

PE/PP

|

PE/PP

|

PE/PP

|

PE/PP

|

|

Screw diameter(m/m)

|

40

|

45

|

55

|

65

|

75

|

90

|

|

Screw L/D ratio(L/D)

|

24/1

|

24/1

|

24/1

|

24/1

|

24/1

|

28/1

|

|

Screw R.P.M speed(r.p.m.)

|

20-66

|

15-61

|

15-60

|

15-60

|

15-58

|

15-58

|

|

Inveter motor(HP)

|

5

|

7.5

|

10

|

15

|

25

|

60

|

|

Oil hydraulic drive motor(HP)

|

5

|

7.5

|

10

|

10

|

15

|

30

|

|

Optional air compressor(HP)

|

7.5

|

7.5

|

10

|

10

|

15

|

20

|

|

Air pressurer(kg/cm2)

|

4-6

|

4-6

|

5-7

|

5-7

|

5-7

|

6-8

|

|

Clamping force(Ton)

|

2.8

|

3.9

|

4.4

|

6.9

|

10

|

5.2

|

|

Oil tank capacity(Gallon)

|

38

|

55

|

60

|

80

|

120

|

250

|

|

Nunber of heaters(ZONE)

|

8

|

8

|

9

|

10

|

10

|

11

|

|

Heating capacity(KW)

|

8.5

|

12

|

15

|

19.3

|

21.5

|

42.8

|

|

Total installed power(KW)

|

16.5

|

23.5

|

32

|

39

|

52.5

|

88

|

|

Extruding capacity per hour(kg/hr)

|

15

|

24

|

36

|

55

|

75

|

100

|

|

Dry cycle per hour(time/hr)

|

1250

|

1000

|

850

|

720

|

650

|

650

|

|

Product capacity(c.c./L)

|

10-125

|

20-325

|

40-825

|

100-1000

|

180-1500

|

1L-3L

|

|

Product weight(g.)

|

3-10

|

5-25

|

10-50

|

10-90

|

15-145

|

80-200

|

|

Min./Max. diameter of product(m/m)

|

10-45

|

20-55

|

30-55

|

30-80

|

30-95

|

60-110

|

|

Extruding mouth outer diameter(m/m)

|

30

|

37

|

40

|

55

|

80

|

98

|

|

Mold center distance(m/m)

|

75+75

|

85+85

|

100+100

|

120+120

|

120+120

|

180+180

|

|

Clamping distance(m/m)

|

120-230

|

130-320

|

140-410

|

150-540

|

160-670

|

160-670

|

|

Length of mold capacity(m/m)

|

100-210

|

146-266

|

155-590

|

160-380

|

223-426

|

288-556

|

|

Width of mold capacity(m/m)

|

200

|

300

|

320

|

430

|

480

|

560

|

|

Machine net weight(kg)

|

2800

|

3400

|

3900

|

4900

|

7900

|

8900

|

|

Machine dimension(m)

|

2.3*1.4*2.2

|

3*1.4*2.3

|

3*1.5*2.3

|

3.2*1.6*2.6

|

4.2*1.7*2.7

|

5.2*1.9*3.5

|

|

MODEL

|

FS-55 PFSO

|

FS-65 PFSO

|

FS-75 PFSO

|

FS-90 PFSO

|

|

Material

|

PE/PP

|

PE/PP

|

PE/PP

|

PE/PP

|

|

Screw diameter(m/m)

|

55

|

65

|

75

|

90

|

|

Screw L/D ratio(L/D)

|

24/1

|

24/1

|

24/1

|

28/1

|

|

Screw R.P.M speed(r.p.m.)

|

15-60

|

15-60

|

15-58

|

15-58

|

|

Inveter motor(HP)

|

15

|

20

|

30

|

60

|

|

Oil hydraulic drive motor(HP)

|

10

|

15

|

15

|

30

|

|

Optional air compressor(HP)

|

15

|

15

|

20

|

20

|

|

Air pressurer(kg/cm2)

|

6-8

|

6-8

|

6-8

|

6-8

|

|

Clamping force(Ton)

|

4.4

|

6.9

|

10

|

5.2

|

|

Oil tank capacity(Gallon)

|

60

|

80

|

120

|

250

|

|

Nunber of heaters(ZONE)

|

11

|

13

|

13

|

11

|

|

Heating capacity(KW)

|

16.5

|

20.8

|

25.7

|

42.8

|

|

Total installed power(KW)

|

37.5

|

48

|

61

|

88

|

|

Extruding capacity per hour(kg/hr)

|

36

|

55

|

75

|

100

|

|

Dry cycle per hour(time/hr)

|

750

|

750

|

650

|

650

|

|

Product capacity(c.c./L)

|

30-200

|

100-500

|

300-1000

|

500-2500

|

|

Product weight(g.)

|

10-25

|

10-40

|

15-90

|

40-170

|

|

Min./Max. diameter of product(m/m)

|

20-55

|

30-55

|

30-90

|

30-90

|

|

Extruding mouth outer diameter(m/m)

|

37

|

42

|

50

|

75

|

|

Mold center distance(m/m)

|

85+85+85

|

85+85+85

|

180+180+180

|

180+180+180

|

|

Clamping distance(m/m)

|

140-410

|

150-540

|

160-670

|

160-670

|

|

Length of mold capacity(m/m)

|

155-290

|

160-380

|

243-466

|

288-556

|

|

Width of mold capacity(m/m)

|

430

|

480

|

520

|

560

|

|

Machine net weight(kg)

|

4100

|

5200

|

8300

|

9300

|

|

Machine dimension(m)

|

3.1*1.8*2.3

|

3.2*1.9*2.6

|

4.3*2*2.7

|

5.2*3.1*3.5

|

|

MODEL

|

FS-45 PSDO

|

FS-55 PSDO

|

FS-65 PSDO

|

FS-75 PSDO

|

FS-90 PSDO

|

FS-100 PSDO

|

|

Material

|

PE/PP

|

PE/PP

|

PE/PP

|

PE/PP

|

PE/PP

|

PE/PP

|

|

Screw diameter(m/m)

|

45

|

55

|

65

|

75

|

90

|

100

|

|

Screw L/D ratio(L/D)

|

24/1

|

24/1

|

24/1

|

24/1

|

28/1

|

28/1

|

|

Screw R.P.M speed(r.p.m.)

|

15-62

|

15-60

|

15-60

|

15-58

|

15-56

|

20-65

|

|

Inveter motor(HP)

|

7.5

|

10

|

15

|

30

|

75

|

75

|

|

Oil hydraulic drive motor(HP)

|

7.5

|

10

|

10

|

15

|

30

|

40

|

|

Optional air compressor(HP)

|

10

|

15

|

15

|

20

|

30

|

30

|

|

Air pressurer(kg/cm2)

|

4-6

|

4-6

|

5-7

|

5-7

|

6-8

|

6-8

|

|

Clamping force(Ton)

|

3.9

|

4.4

|

6.9

|

10

|

5.2

|

6.5

|

|

Oil tank capacity(Gallon)

|

60

|

80

|

120

|

160

|

250

|

300

|

|

Nunber of heaters(ZONE)

|

4

|

4

|

5

|

5

|

11

|

8

|

|

Heating capacity(KW)

|

9.5

|

12.5

|

16.8

|

18

|

20.5

|

36

|

|

Total installed power(KW)

|

22

|

28

|

37

|

53

|

63

|

114

|

|

Extruding capacity per hour(kg/hr)

|

24

|

36

|

55

|

75

|

100

|

180

|

|

Dry cycle per hour(time/hr)

|

1030*2

|

800*2

|

720*2

|

650*2

|

650*2

|

480*2

|

|

Product capacity(c.c./L)

|

40-500

|

65-1250

|

150-2500

|

500-5000

|

5L-10L

|

10L-20L

|

|

Product weight(g.)

|

5-40

|

10-100

|

20-170

|

40-280

|

200-370

|

500-900

|

|

Min./Max. diameter of product(m/m)

|

10-75

|

20-100

|

30-140

|

50-200

|

100-280

|

200-300

|

|

Extruding mouth outer diameter(m/m)

|

56

|

80

|

150

|

200

|

280

|

420

|

|

Mold center distance(m/m)

|

*

|

*

|

*

|

*

|

*

|

*

|

|

Clamping distance(m/m)

|

130-320

|

140-410

|

150-540

|

160-670

|

160-670

|

390-750

|

|

Length of mold capacity(m/m)

|

146-266

|

155-290

|

160-380

|

223-426

|

288-556

|

386-640

|

|

Width of mold capacity(m/m)

|

300

|

320

|

360

|

430

|

520

|

560

|

|

Machine net weight(kg)

|

7000

|

7400

|

7900

|

8500

|

9700

|

11500

|

|

Machine dimension(m)

|

3*1.8*2.5

|

3*1.9*2.5

|

3.2*2*2.8

|

4.2*2.1*2.9

|

5.2*2.3*3.7

|

5.8*3.3*4

|

|

MODEL

|

FS-45 PDDO

|

FS-55 PDDO

|

FS-65 PDDO

|

FS-75 PDDO

|

FS-90 PDDO

|

FS-100 PDDO

|

|

Material

|

PE/PP

|

PE/PP

|

PE/PP

|

PE/PP

|

PE/PP

|

PE/PP

|

|

Screw diameter(m/m)

|

45

|

55

|

65

|

75

|

90

|

100

|

|

Screw L/D ratio(L/D)

|

24/1

|

24/1

|

24/1

|

24/1

|

28/1

|

28/1

|

|

Screw R.P.M speed(r.p.m.)

|

15-61

|

15-60

|

15-60

|

15-58

|

15-56

|

20-65

|

|

Inveter motor(HP)

|

10

|

10

|

15

|

30

|

40

|

75

|

|

Oil hydraulic drive motor(HP)

|

7.5

|

10

|

10

|

15

|

15

|

25

|

|

Optional air compressor(HP)

|

10

|

15

|

15

|

20

|

30

|

30

|

|

Air pressurer(kg/cm2)

|

4-6

|

4-6

|

5-7

|

5-7

|

6-8

|

6-8

|

|

Clamping force(Ton)

|

1.5

|

4.4

|

6.9

|

10

|

13

|

26

|

|

Oil tank capacity(Gallon)

|

60

|

80

|

120

|

160

|

250

|

300

|

|

Nunber of heaters(ZONE)

|

8

|

7

|

8

|

8

|

10

|

10

|

|

Heating capacity(KW)

|

10

|

13.6

|

17.5

|

19

|

22

|

37

|

|

Total installed power(KW)

|

21.5

|

30

|

38

|

54

|

65

|

113

|

|

Extruding capacity per hour(kg/hr)

|

32

|

36

|

55

|

75

|

100

|

180

|

|

Dry cycle per hour(time/hr)

|

1030*2

|

800*2

|

720*2

|

650*2

|

650*2

|

480*2

|

|

Product capacity(c.c./L)

|

30-200

|

40-500

|

100-1000

|

280-2000

|

700-3000

|

2L-6L

|

|

Product weight(g.)

|

4-20

|

5-40

|

10-65

|

20-110

|

40-180

|

110-300

|

|

Min./Max. diameter of product(m/m)

|

10-65

|

20-70

|

30-85

|

40-110

|

50-150

|

100-220

|

|

Extruding mouth outer diameter(m/m)

|

42

|

50

|

65

|

80

|

150

|

200

|

|

Mold center distance(m/m)

|

85

|

120

|

140

|

160

|

220

|

250

|

|

Clamping distance(m/m)

|

130-320

|

140-410

|

150-540

|

160-670

|

160-670

|

390-750

|

|

Length of mold capacity(m/m)

|

146-370

|

155-290

|

160-380

|

223-426

|

288-556

|

385-640

|

|

Width of mold capacity(m/m)

|

300

|

320

|

360

|

430

|

520

|

560

|

|

Machine net weight(kg)

|

7200

|

7600

|

8200

|

9100

|

10100

|

11900

|

|

Machine dimension(m)

|

3*1.4*2.3

|

3.2*2*2.8

|

3.4*3*3

|

4.4*3.1*3.1

|

5.4*3.3*3.9

|

6.4*3.5*5.6

|

|

MODEL

|

FS-55 PTDO

|

FS-65 PTDO

|

FS-75 PTDO

|

FS-90 PTDO

|

|

Material

|

PE/PP

|

PE/PP

|

PE/PP

|

PE/PP

|

|

Screw diameter(m/m)

|

55

|

65

|

75

|

90

|

|

Screw L/D ratio(L/D)

|

24/1

|

24/1

|

24/1

|

28/1

|

|

Screw R.P.M speed(r.p.m.)

|

15-60

|

15-60

|

15-58

|

15-58

|

|

Inveter motor(HP)

|

10

|

15

|

30

|

40

|

|

Oil hydraulic drive motor(HP)

|

10

|

10

|

15

|

15

|

|

Optional air compressor(HP)

|

15

|

15

|

20

|

20

|

|

Air pressurer(kg/cm2)

|

4-6

|

5-7

|

5-7

|

6-8

|

|

Clamping force(Ton)

|

4.4

|

6.9

|

10

|

13

|

|

Oil tank capacity(Gallon)

|

80

|

120

|

160

|

250

|

|

Nunber of heaters(ZONE)

|

9

|

10

|

10

|

12

|

|

Heating capacity(KW)

|

15

|

19.3

|

21.5

|

25

|

|

Total installed power(KW)

|

32

|

40

|

56.5

|

68

|

|

Extruding capacity per hour(kg/hr)

|

36

|

55

|

75

|

100

|

|

Dry cycle per hour(time/hr)

|

850*2

|

720*2

|

650*2

|

650*2

|

|

Product capacity(c.c./L)

|

15-300

|

50-600

|

100-1000

|

280-2000

|

|

Product weight(g.)

|

5-25

|

8-45

|

10-70

|

20-110

|

|

Min./Max. diameter of product(m/m)

|

10-55

|

20-70

|

30-90

|

40-90

|

|

Extruding mouth outer diameter(m/m)

|

40

|

55

|

80

|

98

|

|

Mold center distance(m/m)

|

85+85

|

100+100

|

120+120

|

120+120

|

|

Clamping distance(m/m)

|

140-410

|

150-540

|

160-670

|

160-670

|

|

Length of mold capacity(m/m)

|

155-290

|

160-380

|

233-426

|

288-556

|

|

Width of mold capacity(m/m)

|

320

|

360

|

430

|

520

|

|

Machine net weight(kg)

|

7800

|

8400

|

9400

|

10500

|

|

Machine dimension(m)

|

3.4*2.1*2.8

|

3.6*3.1*3

|

4.4*3.2*3.1

|

5.4*3.4*3.9

|

|

MODEL

|

FS-45 PSSV

|

FS-55 PSSV

|

FS-65 PSSV

|

FS-75 PSSV

|

FS-90 PSSV

|

|

Material

|

PE/PP

|

PE/PP

|

PE/PP

|

PE/PP

|

PE/PP

|

|

Screw diameter(m/m)

|

45/25

|

55/25

|

65/25

|

75/25

|

90/25

|

|

Screw L/D ratio(L/D)

|

24/1

|

24/1

|

24/1

|

24/1

|

28/1

|

|

Screw R.P.M speed(r.p.m.)

|

15-61/5-25

|

15-60/5-25

|

15-60/5-25

|

15-58/5-25

|

15-56/5-25

|

|

Inveter motor(HP)

|

7.5/2

|

10/2

|

15/2

|

25/2

|

60/2

|

|

Oil hydraulic drive motor(HP)

|

7.5

|

10

|

10

|

15

|

30

|

|

Optional air compressor(HP)

|

5

|

7.5

|

7.5

|

10

|

15

|

|

Air pressurer(kg/cm2)

|

4-6

|

4-6

|

5-7

|

5-7

|

6-8

|

|

Clamping force(Ton)

|

3.9

|

4.4

|

6.9

|

9.5

|

5.2

|

|

Oil tank capacity(Gallon)

|

55

|

60

|

80

|

120

|

250

|

|

Nunber of heaters(ZONE)

|

6

|

6

|

7

|

7

|

11

|

|

Heating capacity(KW)

|

11.5

|

14.5

|

18.8

|

23

|

40

|

|

Total installed power(KW)

|

24.5

|

31.5

|

40.5

|

54.5

|

72.5

|

|

Extruding capacity per hour(kg/hr)

|

30

|

42

|

61

|

81

|

106

|

|

Dry cycle per hour(time/hr)

|

1030

|

880

|

720

|

650

|

65

|

|

Product capacity(c.c./L)

|

60-1000

|

150-2500

|

500-5000

|

5L-10L

|

10L-20L

|

|

Product weight(g.)

|

10-100

|

20-170

|

40-280

|

200-370

|

500-900

|

|

Min./Max. diameter of product(m/m)

|

20-100

|

30-140

|

50-200

|

80-260

|

50-340

|

|

Extruding mouth outer diameter(m/m)

|

56

|

80

|

150

|

200

|

280

|

|

Mold center distance(m/m)

|

*

|

*

|

*

|

*

|

*

|

|

Clamping distance(m/m)

|

130-320

|

140-410

|

150-540

|

160-670

|

160-670

|

|

Length of mold capacity(m/m)

|

146-266

|

155-290

|

160-380

|

223-426

|

288-556

|

|

Width of mold capacity(m/m)

|

300

|

320

|

430

|

480

|

600

|

|

Machine net weight(kg)

|

3600

|

3800

|

4700

|

7600

|

8600

|

|

Machine dimension(m)

|

3*1.4*2.9

|

3*1.5*2.9

|

3.6*1.6*3.2

|

4.2*1.7*3.3

|

5.38*2.45*3.43

|

|

MODEL

|

FS-45 PDSV

|

FS-55 PDSV

|

FS-65 PDSV

|

FS-75 PDSV

|

FS-90 PDSV

|

|

Material

|

PE/PP

|

PE/PP

|

PE/PP

|

PE/PP

|

PE/PP

|

|

Screw diameter(m/m)

|

45/25

|

55/25

|

65/25

|

75/25

|

90/25

|

|

Screw L/D ratio(L/D)

|

24/1

|

24/1

|

24/1

|

24/1

|

28/1

|

|

Screw R.P.M speed(r.p.m.)

|

15-61/5-25

|

15-60/5-25

|

15-60/5-25

|

15-58/5-25

|

15-58/5-25

|

|

Inveter motor(HP)

|

7.5/2

|

10/2

|

15/2

|

25/2

|

40/2

|

|

Oil hydraulic drive motor(HP)

|

7.5

|

10

|

10

|

15

|

15

|

|

Optional air compressor(HP)

|

5

|

7.5

|

7.5

|

10

|

15

|

|

Air pressurer(kg/cm2)

|

4-6

|

5-7

|

5-7

|

5-7

|

6-8

|

|

Clamping force(Ton)

|

3.9

|

4.4

|

6.9

|

9.5

|

13

|

|

Oil tank capacity(Gallon)

|

55

|

60

|

80

|

120

|

250

|

|

Nunber of heaters(ZONE)

|

8

|

10

|

10

|

10

|

12

|

|

Heating capacity(KW)

|

14.5

|

18.8

|

20.3

|

25

|

36

|

|

Total installed power(KW)

|

27.5

|

36.5

|

43

|

57

|

80

|

|

Extruding capacity per hour(kg/hr)

|

30

|

42

|

61

|

81

|

106

|

|

Dry cycle per hour(time/hr)

|

1030

|

880

|

720

|

650

|

650

|

|

Product capacity(c.c./L)

|

40-500

|

100-1250

|

280-1800

|

0.5L-2.5L

|

1L-5L

|

|

Product weight(g.)

|

5-40

|

10-100

|

20-170

|

40-170

|

100-160

|

|

Min./Max. diameter of product(m/m)

|

20-70

|

30-85

|

40-100

|

40-130

|

100-160

|

|

Extruding mouth outer diameter(m/m)

|

42

|

50

|

65

|

80

|

150

|

|

Mold center distance(m/m)

|

100

|

120

|

140

|

160

|

200

|

|

Clamping distance(m/m)

|

130-320

|

140-410

|

150-540

|

160-670

|

160-670

|

|

Length of mold capacity(m/m)

|

146-266

|

155-290

|

160-380

|

223-426

|

288-556

|

|

Width of mold capacity(m/m)

|

300

|

320

|

430

|

480

|

560

|

|

Machine net weight(kg)

|

3700

|

3900

|

4800

|

7700

|

8700

|

|

Machine dimension(m)

|

3*1.6*2.9

|

3*1.7*2.9

|

3.6*1.8*3.2

|

4.2*1.9*3.3

|

5.2*2.1*4.1

|

Ejemplos de botellas

Control Paralelo y Lineal de Movimientos de molde

diseño de curvo-brazo para sujeción de molde

Doble estación

SOLICITUD

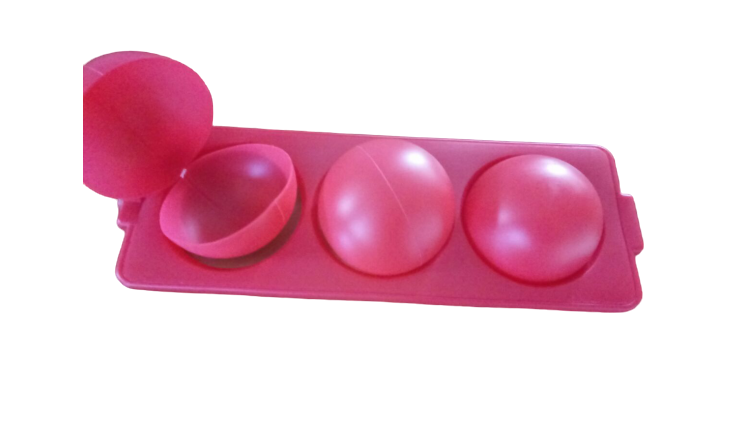

Hand washing bottle / cleaning supplies

Water bottle or specific container

Mask/Closed Wound Drainage Systems

Household/Cleaning product bottle

Outdoor supplies/Bird balls

Closed Wound Drainage Systems

Household/Cleaning product bottle

20L Bucket (20L Jerry can)