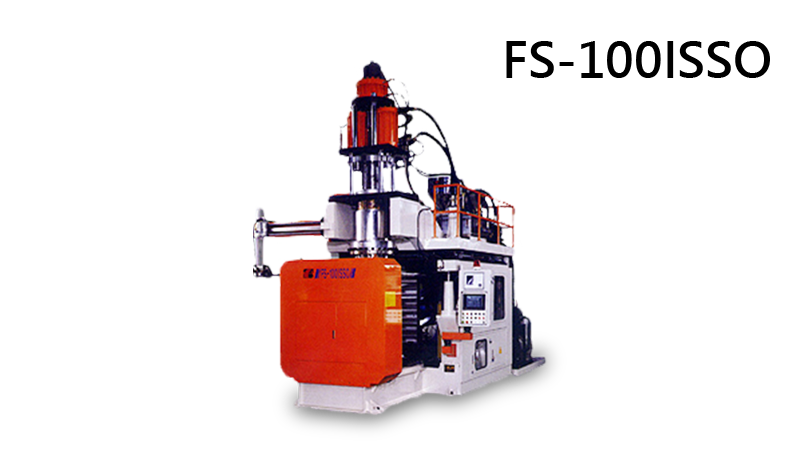

AUTOMATA FLAKONFÚVÓ GÉP I Széria

LEÍRÁS

- A Full Shine I Széria Flakonfúvó gépek alkalmasak nagy méretű különféle termékek gyártására, például szerszámosládák, víztartályok, sörös hordók, autóalkatrészek.

- Ezek a gépek akkumulátoros szerszámfejjel és többpontos harisnya falvastagság szabályzóval vannak felszerelve. Oldalról kiszedő mechanizmus elvén működnek. A keret és a szerszámfej mozgatható a szerszám könnyű cseréje érdekében.

- JELLEMZŐI

- Machine Model

- I Series(Lateral Take-out Mechanism)

- FOTÓK

- Video

- JELLEMZŐI

- LCD Érintőképernyő csatlakozik minden mechanikus és elektronikus funkcióhoz, önellenőrző rendszerrel rendelkezik, mely segíti a problémamegoldást.

- A csiga és henger nitridált bevonatos acélból készült, melynek melegen is nagy a kopásállósága.

- Vízhűtéses szabályzás az adagoló zónák hőmérsékletére.

- A fúvó tüske egy különleges és pontos hűtés cirkulációs és hidraulikus vezérlés rendszerrel rendelkezik (alulról fúvó egység).

- Kapacitás: 30 Litertől 50 Liter

- A Pneumatikus, hidraulikus és elektromos biztonsági felszerelések megvédik a felhasználót a veszélytől és a blaesetektől. További védelem érdekében fényfüggönnyel lehet ellátni a gépet.

- I Széria gépei különböző formájú műanyag termékek gyártására alkalmas.

| EXPOSITION OF FULL SHINE'S MACHINE MODEL |

| SCREW DIAMETER(M/M) | MACHINE SERIES | MOLD HEAD(DIE HEAD) | MOLD STATION | PRODUCT TYPE | |

|---|---|---|---|---|---|

| FS- | 40 | (H) Horizontal | (S) Single Mold Head | (S) Single Mold Station | (O) Original |

| 45 | (P) Parallel | (D) Double Mold Heads | (D) Double Mold Stations | (C) Two Colors | |

| 55 | (O) Standard / Oblique | (T) Three Mold Heads | (D) Two Layers | ||

| 65 | (A) Pneumatic | (F) Four Mold Heads | (T) Three Layers | ||

| 75 | (L) Frontal | (E) Eight Mold Heads | (F) Four Layers | ||

| 80 | (I) Lateral | (L) Six Layers | |||

| 90 | (V) View Stripe | ||||

| 100 | (P) PC baby bottle | ||||

| Example | |||||

| FS- | 65 | P | D | S | D |

| Model | FS-75ISSO | FS-80ISSO | FS-90ISSO | FS-100LSSO | ||

|---|---|---|---|---|---|---|

| Material | PE | PE | PE | PE | ||

| 1 | Product capacity | Liter | 1-10 | 10-30 | 30-50 | 50-100 |

| 2 | Diameter of Product | m/m | 80-260 | 120-350 | 150-400 | 150-580 |

| 3 | Screw diameter | m/m | 75 | 80 | 90 | 100 |

| 4 | Screw L/D ratio | L/D | 24/1 | 24/1 | 24/1 | 28/1 |

| 5 | Extruding capacity | Kg/hr | 100 | 120 | 140 | 180 |

| 6 | Accumulator | Kg | 2.5 | 2.5 | 5 | 7-12 |

| 7 | Screw Drive Inverter motor | HP | 30 | 40 | 50 | - |

| 8 | Screw Drive Hydraulic motor | C.C. | - | 2000 | 2500 | 3000 |

| 9 | Screw ration speed | r.p.m | 15-65 | 20-65 | 20-65 | 20-65 |

| 10 | Oil Hydraulic drive Inverter motor | HP | 15 | 25 | 30 | 40 |

| 11 | Oil Hydraulic drive Hydraulic motor | HP | 15 | 50 | 60 | 75 |

| 12 | Power of thickness control | HP | 5 | 5 | 7.5 | 10 |

| 13 | Air compressor(Optional) | HP | 7.5 | 15 | 15 | 20 |

| 14 | Pressure of air | kg/cm2 | 5-7 | 5-7 | 6-8 | 6-8 |

| 15 | Clamping force | ton | 28 | 32 | 44 | 85 |

| 16 | Oil tank capacity | Gallon | 80 | 100 | 140 | 200 |

| 17 | Number of heaters | Zone | 6 | 7 | 7 | 10 |

| 18 | Heating capacity | Kw | 26 | 28 | 32 | 36 |

| 19 | Total installed power | Kw | 60 | 77 | 92 | 111 |

| 20 | Extruding mouth outer diameter | m/m | 200 | 280 | 350 | 450 |

| 21 | Open close daylight | m/m | 160-670 | 200-800 | 340-850 | 400-1000 |

| 22 | Length of mold capacity | m/m | 200-450 | 300-800 | 850 | 950 |

| 23 | Width of mold capacity | m/m | 450 | 630 | 750 | 1000 |

| 24 | Machine water consumption | L/hr | 900 | 900 | 1000 | 1200 |

| 25 | Mold water consumption | L/min | 230 | 230 | 230 | 230 |

| kcal/hr | 31500 | 31500 | 46623 | 46623 | ||

| 26 | Machine net weight | ton | 7.2 | 11 | 12 | 18 |

| 27 | Machine dimension<L*W*H> | m | 3.8*2.6*2.8 | 4.5*2.6S*2.8 | 5*3*3.3 | 5.5*3.5*3.3 |

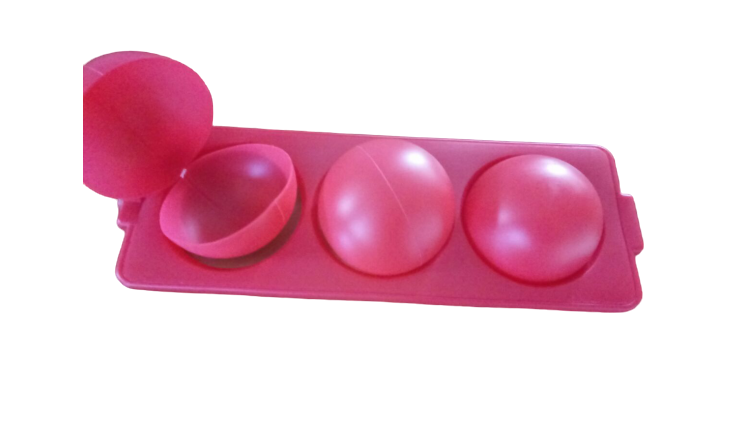

Mintaüvegek

Mintaüvegek

Alulról fújó rendszer

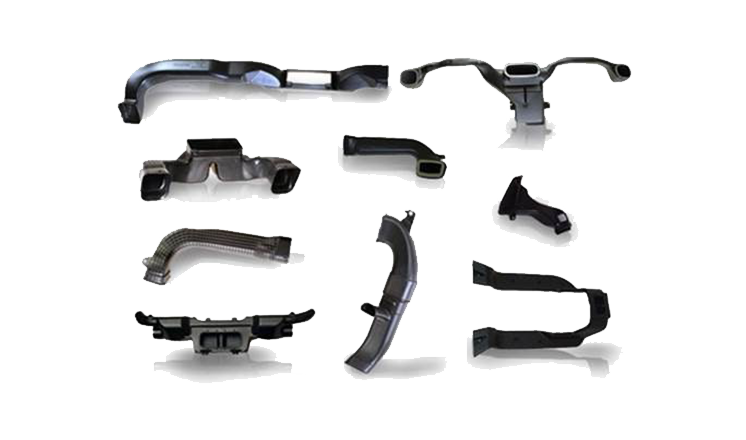

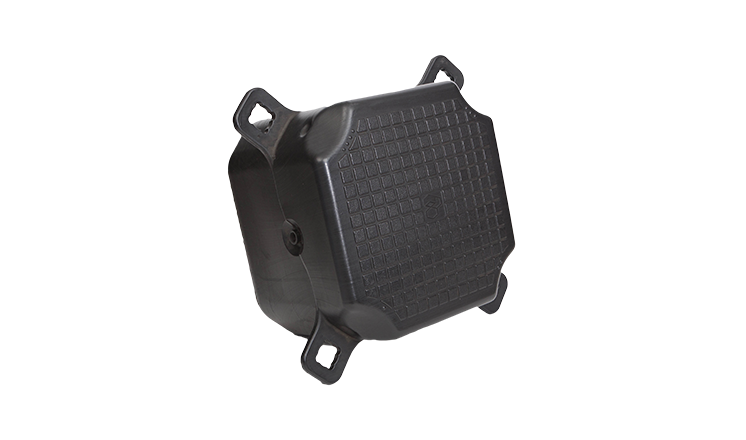

ALKALMAZÁS

Watering cans

Automotive

210L~250L Double L ring drum

Ice bucket / Ice box

Floating bucket

Seat cushion

Outdoor supplies/Bird balls

Water tank

Household/Cosmetics