AUTOMATA FLAKONFÚVÓ GÉP O Széria

LEÍRÁS

-

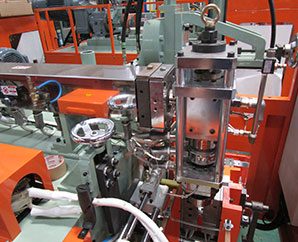

Egy Szerszámfej vagy Dupla szerszámfej és Egy Állomás típus, Alkalmas szintjelző vonalllal rendelkező tartályok gyártására, Automata szállítóval és és a minőségbiztosítás érdekében szivárgás tesztelővel.

- JELLEMZŐI

- Machine Model

- Single Die-head/Single Station

- Double Die-head/Single Station

- Three Die-head/Single Station

- Four Die-head/Single Station

- Single Die-head/Double Station

- Double Die-head/Double Station

- Three Die-head/Double Station

- Four Die-head/Double Station

- FOTÓK

- Video

-

JELLEMZŐI

-

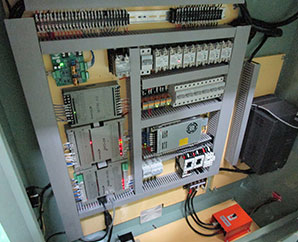

Elektromos Vezérlőpanel.

-

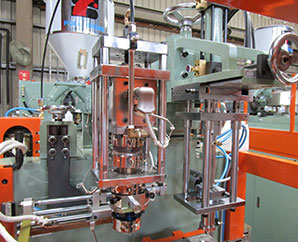

Automata vágórendszerrel, szállítóval, falvastagságvezérléssel van felszerelve.

-

Termékkapacitás: 5ml-200L

-

Extrudáló Csiga a teljes anyag továbbítására.

-

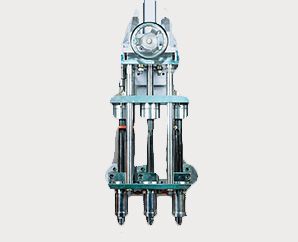

Egyedülálló hidraulikus rendszerrel működtetett fóvótüske, a különféle flakonok nyakának sorjátlanítására.

-

Különleges hűtés a fúvótüske körül a termék nyakának pontos elkészítérére.

|

|

|

EXPOSITION OF FULL SHINE'S MACHINE MODEL

|

|

|

SCREW DIAMETER(M/M)

|

MACHINE SERIES

|

MOLD HEAD(DIE HEAD)

|

MOLD STATION

|

PRODUCT TYPE

|

|

FS-

|

40

|

(H) Horizontal

|

(S) Single Mold Head

|

(S) Single Mold Station

|

(O) Original

|

|

45

|

(P) Parallel

|

(D) Double Mold Heads

|

(D) Double Mold Stations

|

(C) Two Colors

|

|

55

|

(O) Standard / Oblique

|

(T) Three Mold Heads

|

|

(D) Two Layers

|

|

65

|

(A) Pneumatic

|

(F) Four Mold Heads

|

|

(T) Three Layers

|

|

75

|

(L) Frontal

|

(E) Eight Mold Heads

|

|

(F) Four Layers

|

|

80

|

(I) Lateral

|

|

|

(L) Six Layers

|

|

90

|

|

|

|

(V) View Stripe

|

|

100

|

|

|

|

(P) PC baby bottle

|

|

Example

|

|

FS-

|

65

|

P

|

D

|

S

|

D

|

|

MODEL

|

FS-40 OSSO

|

FS-45 OSSO

|

FS-55 OSSO

|

FS-65 OSSO

|

FS-75 OSSO

|

|

Material

|

PE/PP

|

PE/PP

|

PE/PP

|

PE/PP

|

PE/PP

|

|

Screw diameter(m/m)

|

40

|

45

|

55

|

65

|

75

|

|

Screw L/D ratio(L/D)

|

24/1

|

24/1

|

24/1

|

24/1

|

24/1

|

|

Screw R.P.M speed(r.p.m.)

|

20-66

|

15-61

|

15-60

|

15-60

|

15-58

|

|

Inveter motor(HP)

|

5

|

7.5

|

10

|

15

|

25

|

|

Oil hydraulic drive motor(HP)

|

5

|

7.5

|

10

|

10

|

15

|

|

Optional air compressor(HP)

|

5

|

5

|

7.5

|

7.5

|

10

|

|

Air pressurer(kg/cm2)

|

4-6

|

4-6

|

4-6

|

5-7

|

5-7

|

|

Clamping force(Ton)

|

2.8

|

3.9

|

4.4

|

6.9

|

10

|

|

Oil tank capacity(Gallon)

|

38

|

55

|

60

|

80

|

120

|

|

Nunber of heaters(ZONE)

|

4

|

4

|

4

|

5

|

5

|

|

Heating capacity(KW)

|

7

|

9.5

|

12.5

|

16.8

|

18

|

|

Total installed power(KW)

|

15

|

21

|

30

|

35

|

48

|

|

Extruding capacity per hour(kg/hr)

|

15

|

24

|

36

|

55

|

75

|

|

Dry cycle per hour(time/hr)

|

1285

|

1030

|

880

|

720

|

650

|

|

Product capacity(c.c./L)

|

15-500

|

60-1000

|

150-2500

|

500-5000

|

1L-10L

|

|

Product weight(g.)

|

5-40

|

10-100

|

20-170

|

40-280

|

80-500

|

|

Min./Max. diameter of product(m/m)

|

10-75

|

20-100

|

30-140

|

50-200

|

80-260

|

|

Extruding mouth outer diameter(m/m)

|

50

|

56

|

80

|

150

|

200

|

|

Mold center distance(m/m)

|

*

|

*

|

*

|

*

|

*

|

|

Clamping distance(m/m)

|

120-230

|

130-320

|

140-410

|

150-540

|

160-670

|

|

Length of mold capacity(m/m)

|

100-210

|

126-232

|

156-292

|

200-380

|

240-421

|

|

Width of mold capacity(m/m)

|

200

|

290

|

306

|

350

|

425

|

|

Machine net weight(kg)

|

2200

|

2700

|

3200

|

4100

|

7000

|

|

Machine dimension(m)

|

2.3*1.4*2.2

|

3*1.4*2.3

|

3*1.5*2.3

|

3*1.6*2.6

|

4.2*1.7*2.7

|

|

MODEL

|

FS-40 ODSO

|

FS-45 ODSO

|

FS-55 ODSO

|

FS-65 ODSO

|

FS-75 ODSO

|

|

Material

|

PE/PP

|

PE/PP

|

PE/PP

|

PE/PP

|

PE/PP

|

|

Screw diameter(m/m)

|

40

|

45

|

55

|

65

|

75

|

|

Screw L/D ratio(L/D)

|

24/1

|

24/1

|

24/1

|

24/1

|

24/1

|

|

Screw R.P.M speed(r.p.m.)

|

20-66

|

15-61

|

15-60

|

15-60

|

15-58

|

|

Inveter motor(HP)

|

5

|

7.5

|

10

|

15

|

40

|

|

Oil hydraulic drive motor(HP)

|

5

|

7.5

|

10

|

10

|

20/15

|

|

Optional air compressor(HP)

|

5

|

5

|

7.5

|

7.5

|

10

|

|

Air pressurer(kg/cm2)

|

4-6

|

4-6

|

4-6

|

5-7

|

5-7

|

|

Clamping force(Ton)

|

2.8

|

3.9

|

4.4

|

6.9

|

10

|

|

Oil tank capacity(Gallon)

|

38

|

55

|

60

|

80

|

120

|

|

Nunber of heaters(ZONE)

|

6

|

6

|

7

|

8

|

9

|

|

Heating capacity(KW)

|

7.5

|

10.25

|

13.6

|

17.5

|

25

|

|

Total installed power(KW)

|

15

|

21

|

30

|

35

|

48

|

|

Extruding capacity per hour(kg/hr)

|

15

|

24

|

36

|

55

|

75

|

|

Dry cycle per hour(time/hr)

|

1285

|

1030

|

880

|

720

|

650

|

|

Product capacity(c.c./L)

|

15-500

|

40-500

|

100-1250

|

280-1800

|

0.5L-2.5L

|

|

Product weight(g.)

|

4-25

|

5-40

|

10-100

|

20-170

|

40-170

|

|

Min./Max. diameter of product(m/m)

|

10-65

|

20-70

|

30-85

|

40-100

|

40-130

|

|

Extruding mouth outer diameter(m/m)

|

38

|

42

|

50

|

65

|

80

|

|

Mold center distance(m/m)

|

85

|

100

|

120

|

140

|

180

|

|

Clamping distance(m/m)

|

120-230

|

130-320

|

140-410

|

150-540

|

160-670

|

|

Length of mold capacity(m/m)

|

100-210

|

126-232

|

156-292

|

200-380

|

240-421

|

|

Width of mold capacity(m/m)

|

200

|

290

|

306

|

350

|

425

|

|

Machine net weight(kg)

|

2200

|

2700

|

3200

|

4100

|

7000

|

|

Machine dimension(m)

|

2.3*1.4*2.2

|

3*1.4*2.3

|

3*1.5*2.3

|

3*1.6*2.6

|

4.2*1.7*2.7

|

|

MODEL

|

FS-40 OTSO

|

FS-45 OTSO

|

FS-55 OTSO

|

FS-65 OTSO

|

FS-75 OTSO

|

|

Material

|

PE/PP

|

PE/PP

|

PE/PP

|

PE/PP

|

PE/PP

|

|

Screw diameter(m/m)

|

40

|

45

|

55

|

65

|

75

|

|

Screw L/D ratio(L/D)

|

24/1

|

24/1

|

24/1

|

24/1

|

24/1

|

|

Screw R.P.M speed(r.p.m.)

|

20-66

|

15-61

|

15-60

|

15-60

|

15-58

|

|

Inveter motor(HP)

|

5

|

7.5

|

10

|

15

|

25

|

|

Oil hydraulic drive motor(HP)

|

5

|

7.5

|

10

|

10

|

15

|

|

Optional air compressor(HP)

|

7.5

|

7.5

|

10

|

10

|

15

|

|

Air pressurer(kg/cm2)

|

4-6

|

4-6

|

5-7

|

5-7

|

5-7

|

|

Clamping force(Ton)

|

2.8

|

3.9

|

4.4

|

6.9

|

10

|

|

Oil tank capacity(Gallon)

|

38

|

55

|

60

|

80

|

120

|

|

Nunber of heaters(ZONE)

|

8.5

|

12

|

15

|

19.3

|

21.5

|

|

Heating capacity(KW)

|

7.5

|

10.25

|

13.6

|

17.5

|

25

|

|

Total installed power(KW)

|

16.5

|

23.5

|

32

|

39

|

52.5

|

|

Extruding capacity per hour(kg/hr)

|

15

|

24

|

36

|

55

|

75

|

|

Dry cycle per hour(time/hr)

|

1250

|

1000

|

850

|

720

|

650

|

|

Product capacity(c.c./L)

|

10-125

|

20-325

|

40-825

|

100-1000

|

180-4500

|

|

Product weight(g.)

|

3-10

|

5-25

|

10-50

|

10-90

|

15-145

|

|

Min./Max. diameter of product(m/m)

|

10-45

|

20-55

|

30-55

|

30-80

|

95

|

|

Extruding mouth outer diameter(m/m)

|

30

|

37

|

40

|

55

|

80

|

|

Mold center distance(m/m)

|

75+75

|

85+85

|

100+100

|

120+120

|

120+120

|

|

Clamping distance(m/m)

|

120-230

|

130-320

|

140-410

|

150-540

|

160-670

|

|

Length of mold capacity(m/m)

|

100-210

|

126-232

|

156-292

|

200-380

|

243-466

|

|

Width of mold capacity(m/m)

|

200

|

290

|

306

|

350

|

425

|

|

Machine net weight(kg)

|

2500

|

3100

|

3600

|

4600

|

7500

|

|

Machine dimension(m)

|

2.3*1.4*2.2

|

3*1.4*2.3

|

3*1.5*2.3

|

3*1.6*2.6

|

4.2*1.7*2.7

|

|

MODEL

|

FS-55 OFSO

|

FS-65 OFSO

|

FS-75 OFSO

|

FS-90 OFSO

|

|

Material

|

PE/PP

|

PE/PP

|

PE/PP

|

PE/PP

|

|

Screw diameter(m/m)

|

55

|

65

|

75

|

90

|

|

Screw L/D ratio(L/D)

|

24/1

|

24/1

|

24/1

|

28/1

|

|

Screw R.P.M speed(r.p.m.)

|

15-60

|

15-60

|

15-58

|

15-58

|

|

Inveter motor(HP)

|

15

|

20

|

30

|

50

|

|

Oil hydraulic drive motor(HP)

|

10

|

15

|

15

|

15

|

|

Optional air compressor(HP)

|

15

|

15

|

20

|

20

|

|

Air pressurer(kg/cm2)

|

6-8

|

6-8

|

6-8

|

6-8

|

|

Clamping force(Ton)

|

4.4

|

6.9

|

10

|

13

|

|

Oil tank capacity(Gallon)

|

60

|

80

|

120

|

250

|

|

Nunber of heaters(ZONE)

|

11

|

13

|

13

|

15

|

|

Heating capacity(KW)

|

16.5

|

20.8

|

25.7

|

30

|

|

Total installed power(KW)

|

37.5

|

48

|

61

|

80

|

|

Extruding capacity per hour(kg/hr)

|

36

|

55

|

75

|

100

|

|

Dry cycle per hour(time/hr)

|

750

|

750

|

650

|

650

|

|

Product capacity(c.c./L)

|

30-300

|

100-500

|

300-1000

|

500-2500

|

|

Product weight(g.)

|

10-25

|

10-40

|

15-90

|

40-170

|

|

Min./Max. diameter of product(m/m)

|

20-55

|

30-55

|

30-90

|

30-90

|

|

Extruding mouth outer diameter(m/m)

|

37

|

42

|

50

|

75

|

|

Mold center distance(m/m)

|

85+85+85

|

85+85+85

|

120+120+120

|

120+120+120

|

|

Clamping distance(m/m)

|

140-410

|

150-540

|

160-670

|

200-780

|

|

Length of mold capacity(m/m)

|

156-292

|

200-380

|

243-466

|

250-550

|

|

Width of mold capacity(m/m)

|

380

|

430

|

510

|

550

|

|

Machine net weight(kg)

|

3800

|

4800

|

7900

|

8900

|

|

Machine dimension(m)

|

3.1*1.8*2.3

|

3.2*1.9*2.6

|

4.3*2*2.7

|

5.2*3.1*3.5

|

|

MODEL

|

FS-45 OSDO

|

FS-55 OSDO

|

FS-65 OSDO

|

FS-75 OSDO

|

|

Material

|

PE/PP

|

PE/PP

|

PE/PP

|

PE/PP

|

|

Screw diameter(m/m)

|

45

|

55

|

65

|

75

|

|

Screw L/D ratio(L/D)

|

24/1

|

24/1

|

24/1

|

24/1

|

|

Screw R.P.M speed(r.p.m.)

|

15-61

|

15-60

|

15-60

|

15-58

|

|

Inveter motor(HP)

|

7.5

|

10

|

15

|

30

|

|

Oil hydraulic drive motor(HP)

|

7.5

|

10

|

10

|

15

|

|

Optional air compressor(HP)

|

10

|

15

|

15

|

20

|

|

Air pressurer(kg/cm2)

|

4-6

|

4-6

|

5-7

|

5-7

|

|

Clamping force(Ton)

|

3.9

|

4.4

|

6.9

|

10

|

|

Oil tank capacity(Gallon)

|

60

|

80

|

120

|

250

|

|

Nunber of heaters(ZONE)

|

4

|

4

|

5

|

5

|

|

Heating capacity(KW)

|

9.5

|

12.5

|

16.8

|

18

|

|

Total installed power(KW)

|

22

|

28

|

37

|

53

|

|

Extruding capacity per hour(kg/hr)

|

24

|

36

|

55

|

75

|

|

Dry cycle per hour(time/hr)

|

1030*2

|

880*2

|

720*2

|

650*2

|

|

Product capacity(c.c./L)

|

40-500

|

65-1250

|

150-2500

|

500-5000

|

|

Product weight(g.)

|

5-40

|

10-100

|

20-170

|

40-280

|

|

Min./Max. diameter of product(m/m)

|

10-75

|

20-100

|

30-140

|

50-280

|

|

Extruding mouth outer diameter(m/m)

|

56

|

80

|

150

|

200

|

|

Mold center distance(m/m)

|

*

|

*

|

*

|

*

|

|

Clamping distance(m/m)

|

120-320

|

140-410

|

150-540

|

160-670

|

|

Length of mold capacity(m/m)

|

126-232

|

156-292

|

200-380

|

240-640

|

|

Width of mold capacity(m/m)

|

250

|

280

|

380

|

420

|

|

Machine net weight(kg)

|

6400

|

6900

|

7400

|

8300

|

|

Machine dimension(m)

|

3*1.8*2.5

|

3.2*1.9*2.5

|

3.2*2*2.8

|

4.2*2.1*2.9

|

|

MODEL

|

FS-45 OSDO

|

FS-55 OSDO

|

FS-65 OSDO

|

FS-75 OSDO

|

|

Material

|

PE/PP

|

PE/PP

|

PE/PP

|

PE/PP

|

|

Screw diameter(m/m)

|

45

|

55

|

65

|

75

|

|

Screw L/D ratio(L/D)

|

24/1

|

24/1

|

24/1

|

24/1

|

|

Screw R.P.M speed(r.p.m.)

|

15-61

|

15-60

|

15-60

|

15-58

|

|

Inveter motor(HP)

|

10

|

10

|

15

|

30

|

|

Oil hydraulic drive motor(HP)

|

7.5

|

10

|

10

|

15

|

|

Optional air compressor(HP)

|

10

|

15

|

15

|

20

|

|

Air pressurer(kg/cm2)

|

4-6

|

4-6

|

5-7

|

5-7

|

|

Clamping force(Ton)

|

3.9

|

4.4

|

6.9

|

10

|

|

Oil tank capacity(Gallon)

|

60

|

80

|

120

|

160

|

|

Nunber of heaters(ZONE)

|

6

|

7

|

8

|

8

|

|

Heating capacity(KW)

|

10.25

|

13.6

|

17.5

|

19

|

|

Total installed power(KW)

|

26

|

30

|

38

|

54

|

|

Extruding capacity per hour(kg/hr)

|

24

|

36

|

55

|

75

|

|

Dry cycle per hour(time/hr)

|

1030*2

|

880*2

|

720*2

|

650*2

|

|

Product capacity(c.c./L)

|

30-200

|

40-500

|

100-1000

|

280-2000

|

|

Product weight(g.)

|

4-20

|

5-40

|

10-65

|

20-110

|

|

Min./Max. diameter of product(m/m)

|

10-65

|

20-70

|

30-85

|

40-110

|

|

Extruding mouth outer diameter(m/m)

|

42

|

50

|

65

|

80

|

|

Mold center distance(m/m)

|

100

|

120

|

140

|

160

|

|

Clamping distance(m/m)

|

130-320

|

140-410

|

150-540

|

160-670

|

|

Length of mold capacity(m/m)

|

126-232

|

156-292

|

200-380

|

243-466

|

|

Width of mold capacity(m/m)

|

250

|

280

|

380

|

420

|

|

Machine net weight(kg)

|

6500

|

7000

|

7500

|

8500

|

|

Machine dimension(m)

|

3*1.8*2.5

|

3.2*2*2.8

|

3.4*3*3

|

4.2*3.1*3.1

|

|

MODEL

|

FS-55 OTDO

|

FS-65 OTDO

|

FS-75 OTDO

|

|

Material

|

PE/PP

|

PE/PP

|

PE/PP

|

|

Screw diameter(m/m)

|

55

|

65

|

75

|

|

Screw L/D ratio(L/D)

|

24/1

|

24/1

|

24/1

|

|

Screw R.P.M speed(r.p.m.)

|

15-60

|

15-60

|

15-58

|

|

Inveter motor(HP)

|

10

|

15

|

30

|

|

Oil hydraulic drive motor(HP)

|

10

|

10

|

15

|

|

Optional air compressor(HP)

|

15

|

15

|

20

|

|

Air pressurer(kg/cm2)

|

4-6

|

5-7

|

5-7

|

|

Clamping force(Ton)

|

4.4

|

5.7

|

5.7

|

|

Oil tank capacity(Gallon)

|

80

|

120

|

160

|

|

Nunber of heaters(ZONE)

|

9

|

10

|

10

|

|

Heating capacity(KW)

|

15

|

19.3

|

21.5

|

|

Total installed power(KW)

|

32

|

40

|

56.5

|

|

Extruding capacity per hour(kg/hr)

|

36

|

55

|

75

|

|

Dry cycle per hour(time/hr)

|

850*2

|

720*2

|

650*2

|

|

Product capacity(c.c./L)

|

15-300

|

50-600

|

100-1000

|

|

Product weight(g.)

|

5-25

|

8-45

|

10-70

|

|

Min./Max. diameter of product(m/m)

|

10-55

|

20-70

|

30-90

|

|

Extruding mouth outer diameter(m/m)

|

40

|

55

|

80

|

|

Mold center distance(m/m)

|

85+85

|

100+100

|

120+120

|

|

Clamping distance(m/m)

|

140-410

|

150-540

|

160-670

|

|

Length of mold capacity(m/m)

|

156-292

|

200-380

|

243-466

|

|

Width of mold capacity(m/m)

|

300

|

380

|

420

|

|

Machine net weight(kg)

|

7100

|

7600

|

8700

|

|

Machine dimension(m)

|

3.4*2*2.8

|

3.6*3*3

|

4.4*3.1*3.1

|

|

MODEL

|

FS-55 OFDO

|

FS-65 OFDO

|

FS-75 OFDO

|

|

Material

|

PE/PP

|

PE/PP

|

PE/PP

|

|

Screw diameter(m/m)

|

55

|

65

|

75

|

|

Screw L/D ratio(L/D)

|

24/1

|

24/1

|

24/1

|

|

Screw R.P.M speed(r.p.m.)

|

15-60

|

15-60

|

15-58

|

|

Inveter motor(HP)

|

15

|

20

|

30

|

|

Oil hydraulic drive motor(HP)

|

10

|

10

|

15

|

|

Optional air compressor(HP)

|

15

|

15

|

20

|

|

Air pressurer(kg/cm2)

|

6-8

|

6-8

|

6-8

|

|

Clamping force(Ton)

|

4.4

|

6.9

|

13

|

|

Oil tank capacity(Gallon)

|

80

|

120

|

160

|

|

Nunber of heaters(ZONE)

|

11

|

13

|

13

|

|

Heating capacity(KW)

|

16.5

|

20.8

|

25.7

|

|

Total installed power(KW)

|

37.5

|

48

|

61

|

|

Extruding capacity per hour(kg/hr)

|

36

|

55

|

75

|

|

Dry cycle per hour(time/hr)

|

750*2

|

750*2

|

650*2

|

|

Product capacity(c.c./L)

|

50-250

|

100-400

|

200-600

|

|

Product weight(g.)

|

5-20

|

10-30

|

20-50

|

|

Min./Max. diameter of product(m/m)

|

20-55

|

20-55

|

20-70

|

|

Extruding mouth outer diameter(m/m)

|

37

|

42

|

50

|

|

Mold center distance(m/m)

|

85+85

|

85+85

|

120+120

|

|

Clamping distance(m/m)

|

140-410

|

150-410

|

160-670

|

|

Length of mold capacity(m/m)

|

156-292

|

200-380

|

243-466

|

|

Width of mold capacity(m/m)

|

410

|

460

|

520

|

|

Machine net weight(kg)

|

7200

|

7700

|

8900

|

|

Machine dimension(m)

|

3.4*2*3

|

3.6*3.2*3.2

|

4.4*3.3*3.3

|

Mintaüvegek

Mintaüvegek

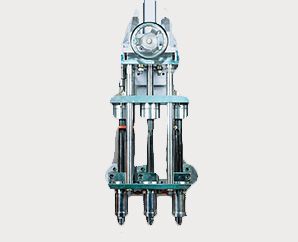

Fúvórendszer

Rendszer a stabil

ALKALMAZÁS

Hand washing bottle / cleaning supplies

Water bottle or specific container

Mask/Closed Wound Drainage Systems

Household/Cleaning product bottle

Outdoor supplies/Bird balls

Closed Wound Drainage Systems

Household/Cleaning product bottle