MÁY THỔI NHỰA TỰ ĐỘNG Dòng sản phẩm H

Giới thiệu

-

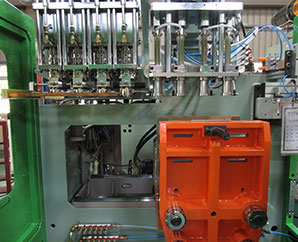

Máy định hình nhựa bằng thổi khí chân không toàn tự động dòng sản phẩm H (kìm khuôn di chuyển bằng phẳng ,đóng mở khuôn điều khiển bằng thanh trượt).

-

Loại máy một kìm và hai kìm có thể phối hợp với một đầu khuôn đến nhiều đầu khuôn,thích hợp dùng để sản xuất các loại nhựa như : PE,PP,PVC vv…

- Đặc tính

- Machine Model

- Single Die-head/Single Station

- Double Die-head/Single Station

- Three Die-head/Single Station

- Four Die-head/Single Station

- Single Die-head/Double Station

- Double Die-head/Double Station

- Three Die-head/Double Station

- Four Die-head/Double Station

- Two-layer/Single Die-head/Single Station

- Two Color/Single Head&Station

- Hình ảnh

- Video

-

Đặc tính

-

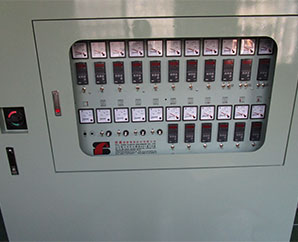

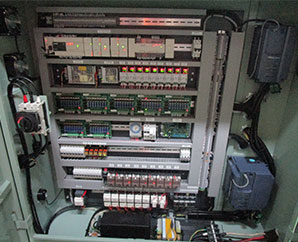

HMI Màn hình máy vi tính cảm ứng (tuỳ chọn) với hệ thống điều khiển PLC,thay đổi dễ dàng,và thuận tiện cho việc bảo trì tại địa phương.

-

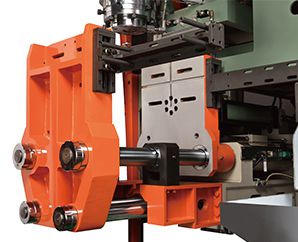

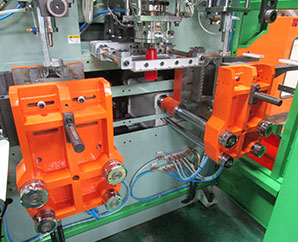

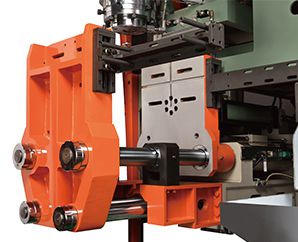

Khuôn mở và đóng sử dụng các loại cột thép tròn, kiểu cách di dời khuôn bằng phẳng hoặc động dựa trên thanh trượt của đức sản xuất.

-

Kiểu cách đơn giản áp dụng cho trục vít chuyển động với một motor biến tần của đức sản xuất.

-

Dạng ngưỡng đầu lên , làm cho liệu xuống nhanh chóng ,để tránh bị dính khuôn.

-

Tính năng thay đổi vị trí chuyển động nhanh trụ thổi khí, với motor thuỷ lực , để tạo thuận lợi cho việc thay thế khuôn và tiết kiệm thời gian,tính năng này là một thiết kế sáng tạo và thuận tiện.

|

|

|

EXPOSITION OF FULL SHINE'S MACHINE MODEL

|

|

|

SCREW DIAMETER(M/M)

|

MACHINE SERIES

|

MOLD HEAD(DIE HEAD)

|

MOLD STATION

|

PRODUCT TYPE

|

|

FS-

|

40

|

(H) Horizontal

|

(S) Single Mold Head

|

(S) Single Mold Station

|

(O) Original

|

|

45

|

(P) Parallel

|

(D) Double Mold Heads

|

(D) Double Mold Stations

|

(C) Two Colors

|

|

55

|

(O) Standard / Oblique

|

(T) Three Mold Heads

|

|

(D) Two Layers

|

|

65

|

(A) Pneumatic

|

(F) Four Mold Heads

|

|

(T) Three Layers

|

|

75

|

(L) Frontal

|

(E) Eight Mold Heads

|

|

(F) Four Layers

|

|

80

|

(I) Lateral

|

|

|

(L) Six Layers

|

|

90

|

|

|

|

(V) View Stripe

|

|

100

|

|

|

|

(P) PC baby bottle

|

|

Example

|

|

FS-

|

65

|

P

|

D

|

S

|

D

|

|

MODEL

|

FS-40 HSSO

|

FS-45 HSSO

|

FS-55 HSSO

|

FS-65 HSSO

|

FS-75 HSSO

|

|

Material

|

PE/PP

|

PE/PP

|

PE/PP

|

PE/PP

|

PE/PP

|

|

Screw diameter(m/m)

|

40

|

45

|

55

|

65

|

75

|

|

Screw L/D ratio(L/D)

|

24/1

|

24/1

|

24/1

|

24/1

|

24/1

|

|

Screw R.P.M speed(r.p.m.)

|

20-66

|

15-61

|

15-60

|

15-60

|

15-58

|

|

Inveter motor(HP)

|

7.5

|

7.5

|

10

|

15

|

25

|

|

Oil hydraulic drive motor(HP)

|

5

|

7.5

|

10

|

10

|

15

|

|

Optional air compressor(HP)

|

5

|

5

|

7.5

|

7.5

|

10

|

|

Air pressurer(kg/cm2)

|

4-6

|

4-6

|

4-6

|

5-7

|

5-7

|

|

Clamping force(Ton)

|

1.5

|

3.9

|

4.4

|

5.6

|

10

|

|

Oil tank capacity(Gallon)

|

38

|

55

|

60

|

80

|

120

|

|

Nunber of heaters(ZONE)

|

5

|

4

|

4

|

6

|

5

|

|

Heating capacity(KW)

|

8

|

9.5

|

12.5

|

16.8

|

18

|

|

Total installed power(KW)

|

18

|

21

|

30

|

35

|

48

|

|

Extruding capacity per hour(kg/hr)

|

15

|

24

|

36

|

55

|

75

|

|

Dry cycle per hour(time/hr)

|

1285

|

1030

|

880

|

720

|

650

|

|

Product capacity(c.c./L)

|

15-500

|

60-1000

|

150-2500

|

500-5000

|

1L-10L

|

|

Product weight(g.)

|

5-40

|

10-100

|

20-170

|

40-280

|

80-500

|

|

Min./Max. diameter of product(m/m)

|

10-75

|

20-100

|

30-140

|

50-200

|

80-260

|

|

Extruding mouth outer diameter(m/m)

|

50

|

56

|

80

|

150

|

200

|

|

Mold center distance(m/m)

|

*

|

*

|

*

|

*

|

*

|

|

Clamping distance(m/m)

|

120-230

|

130-320

|

140-410

|

150-540

|

160-670

|

|

Length of mold capacity(m/m)

|

100-300

|

126-232

|

156-292

|

200-400

|

236-452

|

|

Width of mold capacity(m/m)

|

300

|

300

|

350

|

420

|

480

|

|

Machine net weight(kg)

|

2300

|

2800

|

3300

|

4200

|

7100

|

|

Machine dimension(m)

|

2.9*1.37*2.3

|

3*1.4*2.3

|

3*1.5*2.3

|

3.6*1.6*2.6

|

4.2*1.7*2.7

|

|

MODEL

|

FS-40 HDSO

|

FS-45 HDSO

|

FS-55 HDSO

|

FS-65 HDSO

|

FS-75 HDSO

|

|

Material

|

PE/PP

|

PE/PP

|

PE/PP

|

PE/PP

|

PE/PP

|

|

Screw diameter(m/m)

|

40

|

45

|

55

|

65

|

75

|

|

Screw L/D ratio(L/D)

|

24/1

|

24/1

|

24/1

|

24/1

|

24/1

|

|

Screw R.P.M speed(r.p.m.)

|

20-66

|

15-61

|

15-60

|

15-60

|

15-58

|

|

Inveter motor(HP)

|

5

|

7.5

|

10

|

15

|

40

|

|

Oil hydraulic drive motor(HP)

|

5

|

7.5

|

10

|

10

|

20

|

|

Optional air compressor(HP)

|

5

|

5

|

7.5

|

7.5

|

10

|

|

Air pressurer(kg/cm2)

|

4-6

|

4-6

|

4-6

|

5-7

|

5-7

|

|

Clamping force(Ton)

|

2.8

|

3.9

|

4.4

|

5.6

|

10

|

|

Oil tank capacity(Gallon)

|

38

|

55

|

60

|

80

|

120

|

|

Nunber of heaters(ZONE)

|

6

|

6

|

7

|

9

|

9

|

|

Heating capacity(KW)

|

7.5

|

10.25

|

13.6

|

17.5

|

25

|

|

Total installed power(KW)

|

15.5

|

22

|

33

|

45

|

56

|

|

Extruding capacity per hour(kg/hr)

|

15

|

24

|

36

|

55

|

85

|

|

Dry cycle per hour(time/hr)

|

1285

|

1030

|

880

|

720

|

650

|

|

Product capacity(c.c./L)

|

15-200

|

40-500

|

100-1250

|

280-1800

|

0.5L-2.5L

|

|

Product weight(g.)

|

4-25

|

5-40

|

10-100

|

20-170

|

40-170

|

|

Min./Max. diameter of product(m/m)

|

10-65

|

20-70

|

30-85

|

40-100

|

40-130

|

|

Extruding mouth outer diameter(m/m)

|

38

|

42

|

50

|

65

|

80

|

|

Mold center distance(m/m)

|

85

|

100

|

120

|

160

|

250

|

|

Clamping distance(m/m)

|

120-230

|

130-320

|

140-410

|

150-540

|

160-670

|

|

Length of mold capacity(m/m)

|

100-210

|

126-232

|

156-292

|

200-400

|

236-452

|

|

Width of mold capacity(m/m)

|

230

|

300

|

350

|

420

|

480

|

|

Machine net weight(kg)

|

2400

|

3000

|

3400

|

4400

|

7300

|

|

Machine dimension(m)

|

2.3*1.4*2.2

|

3*1.4*2.3

|

3*1.5*2.3

|

3.8*2.1*2.6

|

4.3*3*2.9

|

|

MODEL

|

FS-40 HTSO

|

FS-45 HTSO

|

FS-55 HTSO

|

FS-65 HTSO

|

FS-75 HTSO

|

|

Material

|

PE/PP

|

PE/PP

|

PE/PP

|

PE/PP

|

PE/PP

|

|

Screw diameter(m/m)

|

40

|

45

|

55

|

65

|

75

|

|

Screw L/D ratio(L/D)

|

24/1

|

24/1

|

24/1

|

24/1

|

24/1

|

|

Screw R.P.M speed(r.p.m.)

|

20-66

|

15-61

|

15-60

|

15-60

|

15-58

|

|

Inveter motor(HP)

|

5

|

7.5

|

10

|

15

|

25

|

|

Oil hydraulic drive motor(HP)

|

5

|

7.5

|

10

|

10

|

15

|

|

Optional air compressor(HP)

|

7.5

|

7.5

|

10

|

10

|

15

|

|

Air pressurer(kg/cm2)

|

4-6

|

4-6

|

5-7

|

5-7

|

5-7

|

|

Clamping force(Ton)

|

2.8

|

3.9

|

4.4

|

6.9

|

10

|

|

Oil tank capacity(Gallon)

|

38

|

55

|

60

|

80

|

120

|

|

Nunber of heaters(ZONE)

|

8

|

8

|

9

|

10

|

10

|

|

Heating capacity(KW)

|

8.5

|

12

|

15

|

19.3

|

21.5

|

|

Total installed power(KW)

|

16.5

|

23.5

|

32

|

47

|

52.5

|

|

Extruding capacity per hour(kg/hr)

|

15

|

24

|

36

|

55

|

75

|

|

Dry cycle per hour(time/hr)

|

1250

|

1000

|

850

|

720

|

650

|

|

Product capacity(c.c./L)

|

10-125

|

20-325

|

40-825

|

100-1000

|

180-1500

|

|

Product weight(g.)

|

3-10

|

5-25

|

10-50

|

10-90

|

15-145

|

|

Min./Max. diameter of product(m/m)

|

10-45

|

20-55

|

30-55

|

30-80

|

30-95

|

|

Extruding mouth outer diameter(m/m)

|

30

|

37

|

40

|

55

|

80

|

|

Mold center distance(m/m)

|

75+75

|

85+85

|

100+100

|

120+120

|

120+120

|

|

Clamping distance(m/m)

|

120-230

|

130-320

|

140-410

|

150-540

|

160-670

|

|

Length of mold capacity(m/m)

|

100-210

|

126-232

|

156-292

|

200-380

|

236-452

|

|

Width of mold capacity(m/m)

|

230

|

300

|

350

|

420

|

480

|

|

Machine net weight(kg)

|

2600

|

3200

|

3700

|

4700

|

7600

|

|

Machine dimension(m)

|

2.3*1.4*2.2

|

3*1.4*2.3

|

3*1.5*2.3

|

3.8*2.1*2.6

|

4.2*1.7*2.7

|

|

MODEL

|

FS-55 HFSO

|

FS-65 HFSO

|

FS-75 HFSO

|

FS-90 HFSO

|

|

Material

|

PE/PP

|

PE/PP

|

PE/PP

|

PE/PP

|

|

Screw diameter(m/m)

|

55

|

65

|

75

|

90

|

|

Screw L/D ratio(L/D)

|

24/1

|

24/1

|

24/1

|

24/1

|

|

Screw R.P.M speed(r.p.m.)

|

15-60

|

15-60

|

15-58

|

15-58

|

|

Inveter motor(HP)

|

15

|

20

|

30

|

50

|

|

Oil hydraulic drive motor(HP)

|

10

|

10

|

15

|

15

|

|

Optional air compressor(HP)

|

15

|

15

|

20

|

20

|

|

Air pressurer(kg/cm2)

|

6-8

|

6-8

|

6-8

|

6-8

|

|

Clamping force(Ton)

|

4.4

|

5.6

|

10

|

13

|

|

Oil tank capacity(Gallon)

|

60

|

80

|

120

|

250

|

|

Nunber of heaters(ZONE)

|

11

|

17

|

13

|

15

|

|

Heating capacity(KW)

|

16.5

|

21.3

|

25.7

|

30

|

|

Total installed power(KW)

|

37.5

|

47

|

61

|

80

|

|

Extruding capacity per hour(kg/hr)

|

36

|

55

|

75

|

10

|

|

Dry cycle per hour(time/hr)

|

750

|

750

|

650

|

650

|

|

Product capacity(c.c./L)

|

30-300

|

100-500

|

300-1000

|

500-2500

|

|

Product weight(g.)

|

10-25

|

10-40

|

15-90

|

40-170

|

|

Min./Max. diameter of product(m/m)

|

20-55

|

30-55

|

30-90

|

30-90

|

|

Extruding mouth outer diameter(m/m)

|

37

|

42

|

50

|

75

|

|

Mold center distance(m/m)

|

90+90

|

90+90

|

120+120

|

120+120

|

|

Clamping distance(m/m)

|

140-410

|

150-540

|

160-670

|

160-670

|

|

Length of mold capacity(m/m)

|

156-292

|

200-380

|

236-452

|

250-550

|

|

Width of mold capacity(m/m)

|

380

|

450

|

510

|

550

|

|

Machine net weight(kg)

|

4000

|

5000

|

7900

|

9500

|

|

Machine dimension(m)

|

3.1*1.8*2.3

|

4.23*2.6*3

|

4.3*2*2.7

|

5.2*3.1*3.5

|

|

MODEL

|

FS-45 HSDO

|

FS-55 HSDO

|

FS-65 HSDO

|

FS-75 HSDO

|

|

Material

|

PE/PP

|

PE/PP

|

PE/PP

|

PE/PP

|

|

Screw diameter(m/m)

|

45

|

55

|

65

|

75

|

|

Screw L/D ratio(L/D)

|

24/1

|

24/1

|

24/1

|

24/1

|

|

Screw R.P.M speed(r.p.m.)

|

15-61

|

15-60

|

15-60

|

15-58

|

|

Inveter motor(HP)

|

7.5

|

10

|

15

|

30

|

|

Oil hydraulic drive motor(HP)

|

7.5

|

10

|

10

|

15

|

|

Optional air compressor(HP)

|

10

|

15

|

15

|

20

|

|

Air pressurer(kg/cm2)

|

4-6

|

4-6

|

5-7

|

5-7

|

|

Clamping force(Ton)

|

3.9

|

4.4

|

6.9

|

10

|

|

Oil tank capacity(Gallon)

|

60

|

80

|

120

|

160

|

|

Nunber of heaters(ZONE)

|

4

|

4

|

5

|

5

|

|

Heating capacity(KW)

|

9.5

|

12.5

|

16.8

|

18

|

|

Total installed power(KW)

|

22

|

28

|

37

|

53

|

|

Extruding capacity per hour(kg/hr)

|

24

|

36

|

55

|

75

|

|

Dry cycle per hour(time/hr)

|

1030*2

|

880*2

|

720*2

|

650*2

|

|

Product capacity(c.c./L)

|

40-500

|

65-1250

|

150-2500

|

500-5000

|

|

Product weight(g.)

|

5-40

|

10-100

|

20-170

|

40-280

|

|

Min./Max. diameter of product(m/m)

|

10-75

|

20-100

|

30-140

|

50-200

|

|

Extruding mouth outer diameter(m/m)

|

56

|

80

|

150

|

200

|

|

Mold center distance(m/m)

|

*

|

*

|

*

|

*

|

|

Clamping distance(m/m)

|

130-320

|

140-410

|

150-540

|

160-670

|

|

Length of mold capacity(m/m)

|

126-232

|

156-292

|

200-380

|

236-452

|

|

Width of mold capacity(m/m)

|

250

|

300

|

330

|

360

|

|

Machine net weight(kg)

|

6400

|

6900

|

7400

|

8300

|

|

Machine dimension(m)

|

3*1.8*2.5

|

3*1.9*2.5

|

3.2*2*2.8

|

4.2*2.1*2.9

|

|

MODEL

|

FS-45 HDDO

|

FS-55 HDDO

|

FS-65 HDDO

|

FS-75 HDDO

|

|

Material

|

PE/PP

|

PE/PP

|

PE/PP

|

PE/PP

|

|

Screw diameter(m/m)

|

45

|

55

|

65

|

75

|

|

Screw L/D ratio(L/D)

|

24/1

|

24/1

|

24/1

|

24/1

|

|

Screw R.P.M speed(r.p.m.)

|

15-61

|

15-60

|

15-60

|

15-58

|

|

Inveter motor(HP)

|

10

|

10

|

15

|

30

|

|

Oil hydraulic drive motor(HP)

|

7.5

|

10

|

10

|

15

|

|

Optional air compressor(HP)

|

10

|

15

|

15

|

20

|

|

Air pressurer(kg/cm2)

|

4-6

|

4-6

|

5-7

|

5-7

|

|

Clamping force(Ton)

|

3.9

|

4.4

|

6.9

|

10

|

|

Oil tank capacity(Gallon)

|

60

|

80

|

120

|

160

|

|

Nunber of heaters(ZONE)

|

6

|

7

|

8

|

8

|

|

Heating capacity(KW)

|

10.25

|

13.6

|

17.5

|

19

|

|

Total installed power(KW)

|

26

|

30

|

38

|

54

|

|

Extruding capacity per hour(kg/hr)

|

32

|

36

|

55

|

75

|

|

Dry cycle per hour(time/hr)

|

1030*2

|

880*2

|

720*2

|

650*2

|

|

Product capacity(c.c./L)

|

30-200

|

40-500

|

100-1000

|

280-2000

|

|

Product weight(g.)

|

4-20

|

5-40

|

10-65

|

20-110

|

|

Min./Max. diameter of product(m/m)

|

10-65

|

20-70

|

30-85

|

40-110

|

|

Extruding mouth outer diameter(m/m)

|

42

|

50

|

65

|

80

|

|

Mold center distance(m/m)

|

100

|

120

|

140

|

160

|

|

Clamping distance(m/m)

|

130-320

|

140-410

|

150-540

|

160-670

|

|

Length of mold capacity(m/m)

|

126-232

|

156-292

|

200-380

|

236-452

|

|

Width of mold capacity(m/m)

|

250

|

300

|

330

|

360

|

|

Machine net weight(kg)

|

6500

|

7000

|

7500

|

8500

|

|

Machine dimension(m)

|

3*1.8*2.5

|

3.2*2*2.8

|

3.4*3*3

|

4.2*3.1*3.1

|

|

MODEL

|

FS-55 HTDO

|

FS-65 HTDO

|

FS-75 HTDO

|

|

Material

|

PE/PP

|

PE/PP

|

PE/PP

|

|

Screw diameter(m/m)

|

55

|

65

|

75

|

|

Screw L/D ratio(L/D)

|

24/1

|

24/1

|

24/1

|

|

Screw R.P.M speed(r.p.m.)

|

15-60

|

15-60

|

15-58

|

|

Inveter motor(HP)

|

10

|

15

|

30

|

|

Oil hydraulic drive motor(HP)

|

10

|

10

|

15

|

|

Optional air compressor(HP)

|

15

|

15

|

20

|

|

Air pressurer(kg/cm2)

|

4-6

|

5-7

|

5-7

|

|

Clamping force(Ton)

|

4.4

|

6.9

|

10

|

|

Oil tank capacity(Gallon)

|

110

|

120

|

160

|

|

Nunber of heaters(ZONE)

|

9

|

10

|

10

|

|

Heating capacity(KW)

|

15

|

19.3

|

21.5

|

|

Total installed power(KW)

|

32

|

40

|

56.5

|

|

Extruding capacity per hour(kg/hr)

|

36

|

55

|

75

|

|

Dry cycle per hour(time/hr)

|

850*2

|

720*2

|

650*2

|

|

Product capacity(c.c./L)

|

15-300

|

50-600

|

100-1000

|

|

Product weight(g.)

|

5-25

|

8-45

|

10-70

|

|

Min./Max. diameter of product(m/m)

|

10-55

|

20-70

|

30-90

|

|

Extruding mouth outer diameter(m/m)

|

40

|

55

|

80

|

|

Mold center distance(m/m)

|

85+85

|

100+100

|

120+120

|

|

Clamping distance(m/m)

|

140-410

|

150-540

|

160-670

|

|

Length of mold capacity(m/m)

|

156-292

|

200-380

|

236-452

|

|

Width of mold capacity(m/m)

|

300

|

330

|

360

|

|

Machine net weight(kg)

|

7100

|

7600

|

8700

|

|

Machine dimension(m)

|

3.4*2*2.8

|

3.6*3*3

|

4.4*3.1*3.1

|

|

MODEL

|

FS-55 HFDO

|

FS-65 HFDO

|

FS-75 HFDO

|

|

Material

|

PE/PP

|

PE/PP

|

PE/PP

|

|

Screw diameter(m/m)

|

55

|

65

|

75

|

|

Screw L/D ratio(L/D)

|

24/1

|

24/1

|

24/1

|

|

Screw R.P.M speed(r.p.m.)

|

15-60

|

15-60

|

15-58

|

|

Inveter motor(HP)

|

15

|

20

|

30

|

|

Oil hydraulic drive motor(HP)

|

10

|

10

|

15

|

|

Optional air compressor(HP)

|

15

|

15

|

20

|

|

Air pressurer(kg/cm2)

|

6-8

|

6-8

|

6-8

|

|

Clamping force(Ton)

|

4.4

|

6.9

|

10

|

|

Oil tank capacity(Gallon)

|

80

|

120

|

160

|

|

Nunber of heaters(ZONE)

|

11

|

13

|

13

|

|

Heating capacity(KW)

|

16.5

|

20.8

|

25.7

|

|

Total installed power(KW)

|

37.5

|

48

|

61

|

|

Extruding capacity per hour(kg/hr)

|

36

|

55

|

75

|

|

Dry cycle per hour(time/hr)

|

750*2

|

750*2

|

650*2

|

|

Product capacity(c.c./L)

|

50-250

|

100-400

|

200-600

|

|

Product weight(g.)

|

5-20

|

10-30

|

20-50

|

|

Min./Max. diameter of product(m/m)

|

20-55

|

20-55

|

20-70

|

|

Extruding mouth outer diameter(m/m)

|

37

|

42

|

50

|

|

Mold center distance(m/m)

|

85+85+85

|

85+85+85

|

100+100+100

|

|

Clamping distance(m/m)

|

140-410

|

150-540

|

160-670

|

|

Length of mold capacity(m/m)

|

156-292

|

200-380

|

236-452

|

|

Width of mold capacity(m/m)

|

300

|

330

|

360

|

|

Machine net weight(kg)

|

7200

|

7700

|

8900

|

|

Machine dimension(m)

|

3.4*2.2*3.1

|

3.6*2.3*3.2

|

4.4*3.3*3.3

|

|

MODEL

|

FS-40 HSSD

|

FS-45 HSSD

|

FS-55 HSSD

|

FS-65 HSSD

|

FS-75 HSSD

|

|

Material

|

PE/PP

|

PE/PP

|

PE/PP

|

PE/PP

|

PE/PP

|

|

Screw diameter(m/m)

|

40/25

|

45/25

|

55/25

|

65/25

|

75/25

|

|

Screw L/D ratio(L/D)

|

24/1

|

24/1

|

24/1

|

24/1

|

24/1

|

|

Screw R.P.M speed(r.p.m.)

|

20-66

|

15-61

|

15-60

|

15-60

|

15-58

|

|

Inveter motor(HP)

|

5/2

|

7.5/2

|

10/2

|

15/2

|

25/2

|

|

Oil hydraulic drive motor(HP)

|

5

|

7.5

|

10

|

10

|

15

|

|

Optional air compressor(HP)

|

5

|

5

|

7.5

|

7.5

|

10

|

|

Air pressurer(kg/cm2)

|

4-6

|

4-6

|

5-7

|

5-7

|

5-7

|

|

Clamping force(Ton)

|

2.8

|

3.9

|

4.4

|

6.9

|

10

|

|

Oil tank capacity(Gallon)

|

38

|

55

|

60

|

80

|

120

|

|

Nunber of heaters(ZONE)

|

6

|

6

|

6

|

7

|

7

|

|

Heating capacity(KW)

|

9.5

|

12

|

15

|

19.5

|

22

|

|

Total installed power(KW)

|

19

|

25

|

32

|

40.5

|

44

|

|

Extruding capacity per hour(kg/hr)

|

15

|

24

|

42

|

55

|

75

|

|

Dry cycle per hour(time/hr)

|

1285

|

1030

|

880

|

720

|

650

|

|

Product capacity(c.c./L)

|

15-500

|

60-1000

|

150-2500

|

1L-5L

|

1L-10L

|

|

Product weight(g.)

|

5-40

|

10-100

|

20-170

|

40-280

|

80-500

|

|

Min./Max. diameter of product(m/m)

|

10-75

|

20-100

|

30-140

|

50-200

|

80-260

|

|

Extruding mouth outer diameter(m/m)

|

50

|

56

|

80

|

150

|

200

|

|

Mold center distance(m/m)

|

*

|

*

|

*

|

*

|

*

|

|

Clamping distance(m/m)

|

120-230

|

130-320

|

140-410

|

150-540

|

160-670

|

|

Length of mold capacity(m/m)

|

126-232

|

156-292

|

200-380

|

236-452

|

236-452

|

|

Width of mold capacity(m/m)

|

230

|

300

|

350

|

420

|

480

|

|

Machine net weight(kg)

|

2600

|

3100

|

3600

|

4500

|

7400

|

|

Machine dimension(m)

|

2.6*1.8*2.7

|

3*1.9*2.8

|

3.3*2*2.9

|

3.6*1.6*3

|

3.9*2.2*3.1

|

|

MODEL

|

FS-55 HSSC

|

FS-65 HSSC

|

FS-75 HSSC

|

|

Material

|

PE/PP

|

PE/PP

|

PE/PP

|

|

Screw diameter(m/m)

|

55/55

|

65/65

|

7575

|

|

Screw L/D ratio(L/D)

|

24/1

|

24/1

|

24/1

|

|

Screw R.P.M speed(r.p.m.)

|

15-60

|

15-60

|

15-58

|

|

Inveter motor(HP)

|

10/10

|

15/15

|

25/25

|

|

Oil hydraulic drive motor(HP)

|

10

|

10

|

15

|

|

Optional air compressor(HP)

|

7.5

|

7.5

|

10

|

|

Air pressurer(kg/cm2)

|

5-7

|

5-7

|

5-7

|

|

Clamping force(Ton)

|

4.4

|

6.9

|

10

|

|

Oil tank capacity(Gallon)

|

60

|

80

|

120

|

|

Nunber of heaters(ZONE)

|

6

|

6

|

7

|

|

Heating capacity(KW)

|

19

|

24.5

|

26

|

|

Total installed power(KW)

|

43

|

56

|

77

|

|

Extruding capacity per hour(kg/hr)

|

42

|

55

|

75

|

|

Dry cycle per hour(time/hr)

|

880

|

720

|

600

|

|

Product capacity(c.c./L)

|

150-2500

|

1L-5L

|

1L-10L

|

|

Product weight(g.)

|

20-170

|

40-280

|

80-500

|

|

Min./Max. diameter of product(m/m)

|

30-140

|

50-200

|

80-260

|

|

Extruding mouth outer diameter(m/m)

|

80

|

150

|

200

|

|

Mold center distance(m/m)

|

*

|

*

|

*

|

|

Clamping distance(m/m)

|

140-540

|

150-540

|

160-670

|

|

Length of mold capacity(m/m)

|

200-380

|

236-452

|

236-452

|

|

Width of mold capacity(m/m)

|

350

|

420

|

480

|

|

Machine net weight(kg)

|

3600

|

4500

|

7400

|

|

Machine dimension(m)

|

3.3*2*2.9

|

3.6*2.1*3

|

3.9*2.2*3.1

|

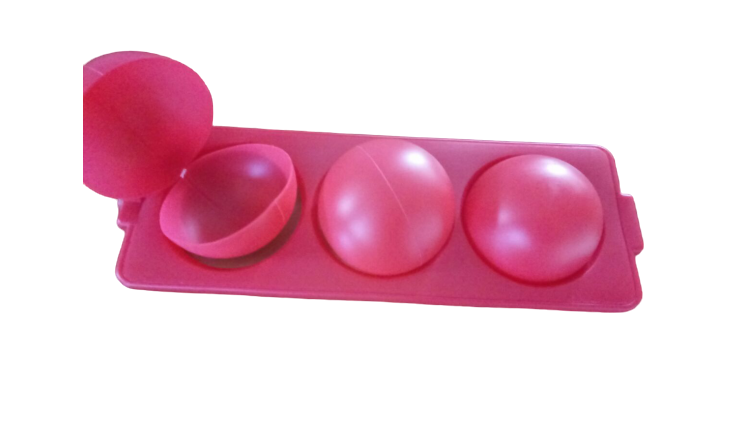

mẫu sản phẩm

Đóng mở khuôn cố định bằng cây trụ, di chuyển khuôn bằng thanh trượt

đóng mở khuôn sử dụng bốn cây cột

motor của đức sản xuất

ỨNG DỤNG

Hand washing bottle / cleaning supplies

Water bottle or specific container

Mask/Closed Wound Drainage Systems

Household/Cleaning product bottle

Outdoor supplies/Bird balls

Closed Wound Drainage Systems

Household/Cleaning product bottle