MÁY THỔI NHỰA TỰ ĐỘNG Dòng sản phẩm P

Giới thiệu

-

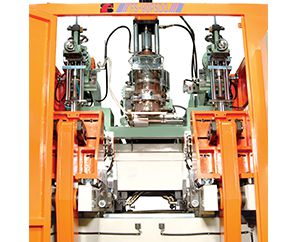

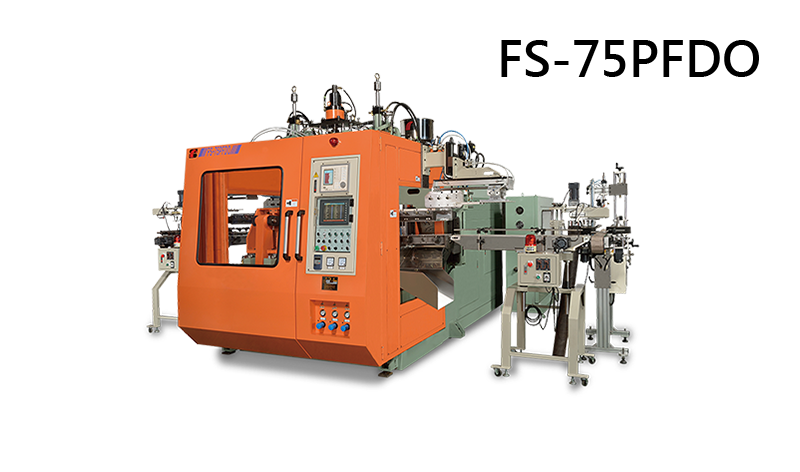

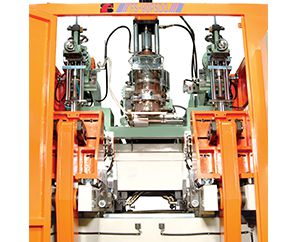

máy định hình nhựa bằng thổi khí chân không (máy thổi nhựa cao tốc) – dòng sản phẩm P (di chuyển khuôn bằng phẳng và đóng mở khuôn bằng thanh trượt.)

- Đặc tính

- Machine Model

- Single Die-head/Single Station

- Double Die-head/Single Station

- Three Die-head/Single Station

- Four Die-head/Single Station

- Single Die-head/Double Station

- Double Die-head/Double Station

- Three Die-head/Double Station

- Single Die-head Single Station Viewstripe

- Double Die-head Single Station Viewstripe

- Hình ảnh

- Video

-

Đặc tính

-

cơ chế đóng khuôn dạng tay quay,hoạt động dựa trên thanh trượt của đức sản xuất ,thay đổi chế độ nhanh chóng và sự ổn định cao.

-

Kiểu cách đơn giản áp dụng cho thiết bị truyền tải trục vít với một motor biến tần của đức chế tạo, đây là một thiết kế tiết kiệm năng lượng.

-

Dạng ngưỡng đầu lên , làm cho liệu nhanh chóng ,tránh dính khuôn , giảm thời gian sản xuất và tạo thuận lợi cho việc điều chỉnh chính xác.

-

Tính năng thay đổi vị trí chuyển động nhanh trụ thổi khí , với motor thuỷ lực , để tạo thuận lợi cho việc thay thế khuôn và tiết kiệm thời gian,tính năng này là một thiết kế sáng tạo và thuận tiện.

-

Hệ thống kim thổi có cài đặt hệ thống rút kim thổi ,làm cho đường kính cổ chai hình thành chính xác.

-

di chduyển khuôn thiết kế thêm hệ thống motor biến tần (Close – Loop) định vị chính xác.

|

|

|

EXPOSITION OF FULL SHINE'S MACHINE MODEL

|

|

|

SCREW DIAMETER(M/M)

|

MACHINE SERIES

|

MOLD HEAD(DIE HEAD)

|

MOLD STATION

|

PRODUCT TYPE

|

|

FS-

|

40

|

(H) Horizontal

|

(S) Single Mold Head

|

(S) Single Mold Station

|

(O) Original

|

|

45

|

(P) Parallel

|

(D) Double Mold Heads

|

(D) Double Mold Stations

|

(C) Two Colors

|

|

55

|

(O) Standard / Oblique

|

(T) Three Mold Heads

|

|

(D) Two Layers

|

|

65

|

(A) Pneumatic

|

(F) Four Mold Heads

|

|

(T) Three Layers

|

|

75

|

(L) Frontal

|

(E) Eight Mold Heads

|

|

(F) Four Layers

|

|

80

|

(I) Lateral

|

|

|

(L) Six Layers

|

|

90

|

|

|

|

(V) View Stripe

|

|

100

|

|

|

|

(P) PC baby bottle

|

|

Example

|

|

FS-

|

65

|

P

|

D

|

S

|

D

|

|

MODEL

|

FS-40 PSSO

|

FS-45 PSSO

|

FS-55 PSSO

|

FS-65 PSSO

|

FS-75 PSSO

|

FS-90 PSSO

|

|

Material

|

PE/PP

|

PE/PP

|

PE/PP

|

PE/PP

|

PE/PP

|

PE/PP

|

|

Screw diameter(m/m)

|

40

|

45

|

55

|

65

|

75

|

90

|

|

Screw L/D ratio(L/D)

|

24/1

|

24/1

|

24/1

|

24/1

|

24/1

|

28/1

|

|

Screw R.P.M speed(r.p.m.)

|

20-66

|

15-61

|

15-60

|

15-60

|

15-58

|

15-56

|

|

Inveter motor(HP)

|

5

|

7.5

|

10

|

15

|

25

|

40

|

|

Oil hydraulic drive motor(HP)

|

5

|

7.5

|

10

|

10

|

15

|

30

|

|

Optional air compressor(HP)

|

5

|

5

|

7.5

|

7.5

|

10

|

15

|

|

Air pressurer(kg/cm2)

|

4-6

|

4-6

|

4-6

|

5-7

|

5-7

|

6-8

|

|

Clamping force(Ton)

|

2.8

|

3.9

|

4.4

|

6.9

|

10

|

5.2

|

|

Oil tank capacity(Gallon)

|

38

|

55

|

60

|

80

|

120

|

250

|

|

Nunber of heaters(ZONE)

|

4

|

4

|

4

|

5

|

5

|

7

|

|

Heating capacity(KW)

|

7

|

9.5

|

12.5

|

16.8

|

18

|

20.5

|

|

Total installed power(KW)

|

15

|

21

|

30

|

43.5

|

48

|

62

|

|

Extruding capacity per hour(kg/hr)

|

15

|

24

|

36

|

55

|

75

|

100

|

|

Dry cycle per hour(time/hr)

|

1285

|

1030

|

880

|

720

|

650

|

650

|

|

Product capacity(c.c./L)

|

15-500

|

60-1000

|

150-2500

|

500-5000

|

5L-10L

|

10L-20L

|

|

Product weight(g.)

|

5-40

|

10-100

|

20-170

|

40-280

|

200-370

|

500-900

|

|

Min./Max. diameter of product(m/m)

|

10-75

|

20-100

|

30-140

|

50-200

|

80-260

|

150-340

|

|

Extruding mouth outer diameter(m/m)

|

50

|

56

|

80

|

150

|

200

|

280

|

|

Mold center distance(m/m)

|

*

|

*

|

*

|

*

|

*

|

*

|

|

Clamping distance(m/m)

|

120-230

|

130-320

|

140-410

|

150-540

|

160-670

|

160-670

|

|

Length of mold capacity(m/m)

|

100-210

|

146-266

|

155-590

|

160-380

|

223-426

|

288-556

|

|

Width of mold capacity(m/m)

|

200

|

300

|

320

|

430

|

480

|

560

|

|

Machine net weight(kg)

|

2500

|

3000

|

3500

|

4400

|

7300

|

8300

|

|

Machine dimension(m)

|

2.3*1.4*2.2

|

3*1.4*2.3

|

3*1.5*2.3

|

3.2*1.6*2.6

|

4.2*1.7*2.7

|

4.1*1.9*3.6

|

|

MODEL

|

FS-40 PDSO

|

FS-45 PDSO

|

FS-55 PDSO

|

FS-65 PDSO

|

FS-75 PDSO

|

FS-90 PDSO

|

|

Material

|

PE/PP

|

PE/PP

|

PE/PP

|

PE/PP

|

PE/PP

|

PE/PP

|

|

Screw diameter(m/m)

|

40

|

45

|

55

|

65

|

75

|

90

|

|

Screw L/D ratio(L/D)

|

24/1

|

24/1

|

24/1

|

24/1

|

24/1

|

28/1

|

|

Screw R.P.M speed(r.p.m.)

|

20-66

|

15-61

|

15-60

|

15-60

|

15-58

|

15-58

|

|

Inveter motor(HP)

|

5

|

7.5

|

10

|

15

|

25

|

60

|

|

Oil hydraulic drive motor(HP)

|

5

|

7.5

|

10

|

10

|

15

|

30

|

|

Optional air compressor(HP)

|

5

|

5

|

7.5

|

7.5

|

10

|

15

|

|

Air pressurer(kg/cm2)

|

4-6

|

4-6

|

5-7

|

5-7

|

5-7

|

6-8

|

|

Clamping force(Ton)

|

2.8

|

3.9

|

4.4

|

6.9

|

10

|

5.2

|

|

Oil tank capacity(Gallon)

|

38

|

55

|

60

|

80

|

120

|

250

|

|

Nunber of heaters(ZONE)

|

6

|

6

|

7

|

8

|

8

|

11

|

|

Heating capacity(KW)

|

7

|

10.25

|

13.6

|

17.5

|

19

|

33

|

|

Total installed power(KW)

|

15.5

|

22

|

29.5

|

37

|

50

|

67

|

|

Extruding capacity per hour(kg/hr)

|

15

|

24

|

36

|

55

|

75

|

100

|

|

Dry cycle per hour(time/hr)

|

1285

|

1030

|

880

|

720

|

650

|

650

|

|

Product capacity(c.c./L)

|

15-200

|

50-500

|

100-1250

|

280-1800

|

0.5L-2.5L

|

1L-5L

|

|

Product weight(g.)

|

4-25

|

5-40

|

10-100

|

20-170

|

40-170

|

80-280

|

|

Min./Max. diameter of product(m/m)

|

10-65

|

20-70

|

30-85

|

40-100

|

40-130

|

100-160

|

|

Extruding mouth outer diameter(m/m)

|

38

|

42

|

50

|

65

|

80

|

150

|

|

Mold center distance(m/m)

|

85

|

100

|

120

|

140

|

160

|

180

|

|

Clamping distance(m/m)

|

120-230

|

130-320

|

140-410

|

150-540

|

160-670

|

160-670

|

|

Length of mold capacity(m/m)

|

100-210

|

146-266

|

155-590

|

160-380

|

223-426

|

288-556

|

|

Width of mold capacity(m/m)

|

200

|

300

|

320

|

430

|

480

|

560

|

|

Machine net weight(kg)

|

2600

|

3200

|

3700

|

4600

|

7500

|

8500

|

|

Machine dimension(m)

|

2.3*1.4*2.2

|

3*1.4*2.3

|

3*1.5*2.3

|

3.2*1.6*2.6

|

4.2*1.7*2.7

|

5.2*1.9*3.5

|

|

MODEL

|

FS-40 PTSO

|

FS-45 PTSO

|

FS-55 PTSO

|

FS-65 PTSO

|

FS-75 PTSO

|

FS-90 PTSO

|

|

Material

|

PE/PP

|

PE/PP

|

PE/PP

|

PE/PP

|

PE/PP

|

PE/PP

|

|

Screw diameter(m/m)

|

40

|

45

|

55

|

65

|

75

|

90

|

|

Screw L/D ratio(L/D)

|

24/1

|

24/1

|

24/1

|

24/1

|

24/1

|

28/1

|

|

Screw R.P.M speed(r.p.m.)

|

20-66

|

15-61

|

15-60

|

15-60

|

15-58

|

15-58

|

|

Inveter motor(HP)

|

5

|

7.5

|

10

|

15

|

25

|

60

|

|

Oil hydraulic drive motor(HP)

|

5

|

7.5

|

10

|

10

|

15

|

30

|

|

Optional air compressor(HP)

|

7.5

|

7.5

|

10

|

10

|

15

|

20

|

|

Air pressurer(kg/cm2)

|

4-6

|

4-6

|

5-7

|

5-7

|

5-7

|

6-8

|

|

Clamping force(Ton)

|

2.8

|

3.9

|

4.4

|

6.9

|

10

|

5.2

|

|

Oil tank capacity(Gallon)

|

38

|

55

|

60

|

80

|

120

|

250

|

|

Nunber of heaters(ZONE)

|

8

|

8

|

9

|

10

|

10

|

11

|

|

Heating capacity(KW)

|

8.5

|

12

|

15

|

19.3

|

21.5

|

42.8

|

|

Total installed power(KW)

|

16.5

|

23.5

|

32

|

39

|

52.5

|

88

|

|

Extruding capacity per hour(kg/hr)

|

15

|

24

|

36

|

55

|

75

|

100

|

|

Dry cycle per hour(time/hr)

|

1250

|

1000

|

850

|

720

|

650

|

650

|

|

Product capacity(c.c./L)

|

10-125

|

20-325

|

40-825

|

100-1000

|

180-1500

|

1L-3L

|

|

Product weight(g.)

|

3-10

|

5-25

|

10-50

|

10-90

|

15-145

|

80-200

|

|

Min./Max. diameter of product(m/m)

|

10-45

|

20-55

|

30-55

|

30-80

|

30-95

|

60-110

|

|

Extruding mouth outer diameter(m/m)

|

30

|

37

|

40

|

55

|

80

|

98

|

|

Mold center distance(m/m)

|

75+75

|

85+85

|

100+100

|

120+120

|

120+120

|

180+180

|

|

Clamping distance(m/m)

|

120-230

|

130-320

|

140-410

|

150-540

|

160-670

|

160-670

|

|

Length of mold capacity(m/m)

|

100-210

|

146-266

|

155-590

|

160-380

|

223-426

|

288-556

|

|

Width of mold capacity(m/m)

|

200

|

300

|

320

|

430

|

480

|

560

|

|

Machine net weight(kg)

|

2800

|

3400

|

3900

|

4900

|

7900

|

8900

|

|

Machine dimension(m)

|

2.3*1.4*2.2

|

3*1.4*2.3

|

3*1.5*2.3

|

3.2*1.6*2.6

|

4.2*1.7*2.7

|

5.2*1.9*3.5

|

|

MODEL

|

FS-55 PFSO

|

FS-65 PFSO

|

FS-75 PFSO

|

FS-90 PFSO

|

|

Material

|

PE/PP

|

PE/PP

|

PE/PP

|

PE/PP

|

|

Screw diameter(m/m)

|

55

|

65

|

75

|

90

|

|

Screw L/D ratio(L/D)

|

24/1

|

24/1

|

24/1

|

28/1

|

|

Screw R.P.M speed(r.p.m.)

|

15-60

|

15-60

|

15-58

|

15-58

|

|

Inveter motor(HP)

|

15

|

20

|

30

|

60

|

|

Oil hydraulic drive motor(HP)

|

10

|

15

|

15

|

30

|

|

Optional air compressor(HP)

|

15

|

15

|

20

|

20

|

|

Air pressurer(kg/cm2)

|

6-8

|

6-8

|

6-8

|

6-8

|

|

Clamping force(Ton)

|

4.4

|

6.9

|

10

|

5.2

|

|

Oil tank capacity(Gallon)

|

60

|

80

|

120

|

250

|

|

Nunber of heaters(ZONE)

|

11

|

13

|

13

|

11

|

|

Heating capacity(KW)

|

16.5

|

20.8

|

25.7

|

42.8

|

|

Total installed power(KW)

|

37.5

|

48

|

61

|

88

|

|

Extruding capacity per hour(kg/hr)

|

36

|

55

|

75

|

100

|

|

Dry cycle per hour(time/hr)

|

750

|

750

|

650

|

650

|

|

Product capacity(c.c./L)

|

30-200

|

100-500

|

300-1000

|

500-2500

|

|

Product weight(g.)

|

10-25

|

10-40

|

15-90

|

40-170

|

|

Min./Max. diameter of product(m/m)

|

20-55

|

30-55

|

30-90

|

30-90

|

|

Extruding mouth outer diameter(m/m)

|

37

|

42

|

50

|

75

|

|

Mold center distance(m/m)

|

85+85+85

|

85+85+85

|

180+180+180

|

180+180+180

|

|

Clamping distance(m/m)

|

140-410

|

150-540

|

160-670

|

160-670

|

|

Length of mold capacity(m/m)

|

155-290

|

160-380

|

243-466

|

288-556

|

|

Width of mold capacity(m/m)

|

430

|

480

|

520

|

560

|

|

Machine net weight(kg)

|

4100

|

5200

|

8300

|

9300

|

|

Machine dimension(m)

|

3.1*1.8*2.3

|

3.2*1.9*2.6

|

4.3*2*2.7

|

5.2*3.1*3.5

|

|

MODEL

|

FS-45 PSDO

|

FS-55 PSDO

|

FS-65 PSDO

|

FS-75 PSDO

|

FS-90 PSDO

|

FS-100 PSDO

|

|

Material

|

PE/PP

|

PE/PP

|

PE/PP

|

PE/PP

|

PE/PP

|

PE/PP

|

|

Screw diameter(m/m)

|

45

|

55

|

65

|

75

|

90

|

100

|

|

Screw L/D ratio(L/D)

|

24/1

|

24/1

|

24/1

|

24/1

|

28/1

|

28/1

|

|

Screw R.P.M speed(r.p.m.)

|

15-62

|

15-60

|

15-60

|

15-58

|

15-56

|

20-65

|

|

Inveter motor(HP)

|

7.5

|

10

|

15

|

30

|

75

|

75

|

|

Oil hydraulic drive motor(HP)

|

7.5

|

10

|

10

|

15

|

30

|

40

|

|

Optional air compressor(HP)

|

10

|

15

|

15

|

20

|

30

|

30

|

|

Air pressurer(kg/cm2)

|

4-6

|

4-6

|

5-7

|

5-7

|

6-8

|

6-8

|

|

Clamping force(Ton)

|

3.9

|

4.4

|

6.9

|

10

|

5.2

|

6.5

|

|

Oil tank capacity(Gallon)

|

60

|

80

|

120

|

160

|

250

|

300

|

|

Nunber of heaters(ZONE)

|

4

|

4

|

5

|

5

|

11

|

8

|

|

Heating capacity(KW)

|

9.5

|

12.5

|

16.8

|

18

|

20.5

|

36

|

|

Total installed power(KW)

|

22

|

28

|

37

|

53

|

63

|

114

|

|

Extruding capacity per hour(kg/hr)

|

24

|

36

|

55

|

75

|

100

|

180

|

|

Dry cycle per hour(time/hr)

|

1030*2

|

800*2

|

720*2

|

650*2

|

650*2

|

480*2

|

|

Product capacity(c.c./L)

|

40-500

|

65-1250

|

150-2500

|

500-5000

|

5L-10L

|

10L-20L

|

|

Product weight(g.)

|

5-40

|

10-100

|

20-170

|

40-280

|

200-370

|

500-900

|

|

Min./Max. diameter of product(m/m)

|

10-75

|

20-100

|

30-140

|

50-200

|

100-280

|

200-300

|

|

Extruding mouth outer diameter(m/m)

|

56

|

80

|

150

|

200

|

280

|

420

|

|

Mold center distance(m/m)

|

*

|

*

|

*

|

*

|

*

|

*

|

|

Clamping distance(m/m)

|

130-320

|

140-410

|

150-540

|

160-670

|

160-670

|

390-750

|

|

Length of mold capacity(m/m)

|

146-266

|

155-290

|

160-380

|

223-426

|

288-556

|

386-640

|

|

Width of mold capacity(m/m)

|

300

|

320

|

360

|

430

|

520

|

560

|

|

Machine net weight(kg)

|

7000

|

7400

|

7900

|

8500

|

9700

|

11500

|

|

Machine dimension(m)

|

3*1.8*2.5

|

3*1.9*2.5

|

3.2*2*2.8

|

4.2*2.1*2.9

|

5.2*2.3*3.7

|

5.8*3.3*4

|

|

MODEL

|

FS-45 PDDO

|

FS-55 PDDO

|

FS-65 PDDO

|

FS-75 PDDO

|

FS-90 PDDO

|

FS-100 PDDO

|

|

Material

|

PE/PP

|

PE/PP

|

PE/PP

|

PE/PP

|

PE/PP

|

PE/PP

|

|

Screw diameter(m/m)

|

45

|

55

|

65

|

75

|

90

|

100

|

|

Screw L/D ratio(L/D)

|

24/1

|

24/1

|

24/1

|

24/1

|

28/1

|

28/1

|

|

Screw R.P.M speed(r.p.m.)

|

15-61

|

15-60

|

15-60

|

15-58

|

15-56

|

20-65

|

|

Inveter motor(HP)

|

10

|

10

|

15

|

30

|

40

|

75

|

|

Oil hydraulic drive motor(HP)

|

7.5

|

10

|

10

|

15

|

15

|

25

|

|

Optional air compressor(HP)

|

10

|

15

|

15

|

20

|

30

|

30

|

|

Air pressurer(kg/cm2)

|

4-6

|

4-6

|

5-7

|

5-7

|

6-8

|

6-8

|

|

Clamping force(Ton)

|

1.5

|

4.4

|

6.9

|

10

|

13

|

26

|

|

Oil tank capacity(Gallon)

|

60

|

80

|

120

|

160

|

250

|

300

|

|

Nunber of heaters(ZONE)

|

8

|

7

|

8

|

8

|

10

|

10

|

|

Heating capacity(KW)

|

10

|

13.6

|

17.5

|

19

|

22

|

37

|

|

Total installed power(KW)

|

21.5

|

30

|

38

|

54

|

65

|

113

|

|

Extruding capacity per hour(kg/hr)

|

32

|

36

|

55

|

75

|

100

|

180

|

|

Dry cycle per hour(time/hr)

|

1030*2

|

800*2

|

720*2

|

650*2

|

650*2

|

480*2

|

|

Product capacity(c.c./L)

|

30-200

|

40-500

|

100-1000

|

280-2000

|

700-3000

|

2L-6L

|

|

Product weight(g.)

|

4-20

|

5-40

|

10-65

|

20-110

|

40-180

|

110-300

|

|

Min./Max. diameter of product(m/m)

|

10-65

|

20-70

|

30-85

|

40-110

|

50-150

|

100-220

|

|

Extruding mouth outer diameter(m/m)

|

42

|

50

|

65

|

80

|

150

|

200

|

|

Mold center distance(m/m)

|

85

|

120

|

140

|

160

|

220

|

250

|

|

Clamping distance(m/m)

|

130-320

|

140-410

|

150-540

|

160-670

|

160-670

|

390-750

|

|

Length of mold capacity(m/m)

|

146-370

|

155-290

|

160-380

|

223-426

|

288-556

|

385-640

|

|

Width of mold capacity(m/m)

|

300

|

320

|

360

|

430

|

520

|

560

|

|

Machine net weight(kg)

|

7200

|

7600

|

8200

|

9100

|

10100

|

11900

|

|

Machine dimension(m)

|

3*1.4*2.3

|

3.2*2*2.8

|

3.4*3*3

|

4.4*3.1*3.1

|

5.4*3.3*3.9

|

6.4*3.5*5.6

|

|

MODEL

|

FS-55 PTDO

|

FS-65 PTDO

|

FS-75 PTDO

|

FS-90 PTDO

|

|

Material

|

PE/PP

|

PE/PP

|

PE/PP

|

PE/PP

|

|

Screw diameter(m/m)

|

55

|

65

|

75

|

90

|

|

Screw L/D ratio(L/D)

|

24/1

|

24/1

|

24/1

|

28/1

|

|

Screw R.P.M speed(r.p.m.)

|

15-60

|

15-60

|

15-58

|

15-58

|

|

Inveter motor(HP)

|

10

|

15

|

30

|

40

|

|

Oil hydraulic drive motor(HP)

|

10

|

10

|

15

|

15

|

|

Optional air compressor(HP)

|

15

|

15

|

20

|

20

|

|

Air pressurer(kg/cm2)

|

4-6

|

5-7

|

5-7

|

6-8

|

|

Clamping force(Ton)

|

4.4

|

6.9

|

10

|

13

|

|

Oil tank capacity(Gallon)

|

80

|

120

|

160

|

250

|

|

Nunber of heaters(ZONE)

|

9

|

10

|

10

|

12

|

|

Heating capacity(KW)

|

15

|

19.3

|

21.5

|

25

|

|

Total installed power(KW)

|

32

|

40

|

56.5

|

68

|

|

Extruding capacity per hour(kg/hr)

|

36

|

55

|

75

|

100

|

|

Dry cycle per hour(time/hr)

|

850*2

|

720*2

|

650*2

|

650*2

|

|

Product capacity(c.c./L)

|

15-300

|

50-600

|

100-1000

|

280-2000

|

|

Product weight(g.)

|

5-25

|

8-45

|

10-70

|

20-110

|

|

Min./Max. diameter of product(m/m)

|

10-55

|

20-70

|

30-90

|

40-90

|

|

Extruding mouth outer diameter(m/m)

|

40

|

55

|

80

|

98

|

|

Mold center distance(m/m)

|

85+85

|

100+100

|

120+120

|

120+120

|

|

Clamping distance(m/m)

|

140-410

|

150-540

|

160-670

|

160-670

|

|

Length of mold capacity(m/m)

|

155-290

|

160-380

|

233-426

|

288-556

|

|

Width of mold capacity(m/m)

|

320

|

360

|

430

|

520

|

|

Machine net weight(kg)

|

7800

|

8400

|

9400

|

10500

|

|

Machine dimension(m)

|

3.4*2.1*2.8

|

3.6*3.1*3

|

4.4*3.2*3.1

|

5.4*3.4*3.9

|

|

MODEL

|

FS-45 PSSV

|

FS-55 PSSV

|

FS-65 PSSV

|

FS-75 PSSV

|

FS-90 PSSV

|

|

Material

|

PE/PP

|

PE/PP

|

PE/PP

|

PE/PP

|

PE/PP

|

|

Screw diameter(m/m)

|

45/25

|

55/25

|

65/25

|

75/25

|

90/25

|

|

Screw L/D ratio(L/D)

|

24/1

|

24/1

|

24/1

|

24/1

|

28/1

|

|

Screw R.P.M speed(r.p.m.)

|

15-61/5-25

|

15-60/5-25

|

15-60/5-25

|

15-58/5-25

|

15-56/5-25

|

|

Inveter motor(HP)

|

7.5/2

|

10/2

|

15/2

|

25/2

|

60/2

|

|

Oil hydraulic drive motor(HP)

|

7.5

|

10

|

10

|

15

|

30

|

|

Optional air compressor(HP)

|

5

|

7.5

|

7.5

|

10

|

15

|

|

Air pressurer(kg/cm2)

|

4-6

|

4-6

|

5-7

|

5-7

|

6-8

|

|

Clamping force(Ton)

|

3.9

|

4.4

|

6.9

|

9.5

|

5.2

|

|

Oil tank capacity(Gallon)

|

55

|

60

|

80

|

120

|

250

|

|

Nunber of heaters(ZONE)

|

6

|

6

|

7

|

7

|

11

|

|

Heating capacity(KW)

|

11.5

|

14.5

|

18.8

|

23

|

40

|

|

Total installed power(KW)

|

24.5

|

31.5

|

40.5

|

54.5

|

72.5

|

|

Extruding capacity per hour(kg/hr)

|

30

|

42

|

61

|

81

|

106

|

|

Dry cycle per hour(time/hr)

|

1030

|

880

|

720

|

650

|

65

|

|

Product capacity(c.c./L)

|

60-1000

|

150-2500

|

500-5000

|

5L-10L

|

10L-20L

|

|

Product weight(g.)

|

10-100

|

20-170

|

40-280

|

200-370

|

500-900

|

|

Min./Max. diameter of product(m/m)

|

20-100

|

30-140

|

50-200

|

80-260

|

50-340

|

|

Extruding mouth outer diameter(m/m)

|

56

|

80

|

150

|

200

|

280

|

|

Mold center distance(m/m)

|

*

|

*

|

*

|

*

|

*

|

|

Clamping distance(m/m)

|

130-320

|

140-410

|

150-540

|

160-670

|

160-670

|

|

Length of mold capacity(m/m)

|

146-266

|

155-290

|

160-380

|

223-426

|

288-556

|

|

Width of mold capacity(m/m)

|

300

|

320

|

430

|

480

|

600

|

|

Machine net weight(kg)

|

3600

|

3800

|

4700

|

7600

|

8600

|

|

Machine dimension(m)

|

3*1.4*2.9

|

3*1.5*2.9

|

3.6*1.6*3.2

|

4.2*1.7*3.3

|

5.38*2.45*3.43

|

|

MODEL

|

FS-45 PDSV

|

FS-55 PDSV

|

FS-65 PDSV

|

FS-75 PDSV

|

FS-90 PDSV

|

|

Material

|

PE/PP

|

PE/PP

|

PE/PP

|

PE/PP

|

PE/PP

|

|

Screw diameter(m/m)

|

45/25

|

55/25

|

65/25

|

75/25

|

90/25

|

|

Screw L/D ratio(L/D)

|

24/1

|

24/1

|

24/1

|

24/1

|

28/1

|

|

Screw R.P.M speed(r.p.m.)

|

15-61/5-25

|

15-60/5-25

|

15-60/5-25

|

15-58/5-25

|

15-58/5-25

|

|

Inveter motor(HP)

|

7.5/2

|

10/2

|

15/2

|

25/2

|

40/2

|

|

Oil hydraulic drive motor(HP)

|

7.5

|

10

|

10

|

15

|

15

|

|

Optional air compressor(HP)

|

5

|

7.5

|

7.5

|

10

|

15

|

|

Air pressurer(kg/cm2)

|

4-6

|

5-7

|

5-7

|

5-7

|

6-8

|

|

Clamping force(Ton)

|

3.9

|

4.4

|

6.9

|

9.5

|

13

|

|

Oil tank capacity(Gallon)

|

55

|

60

|

80

|

120

|

250

|

|

Nunber of heaters(ZONE)

|

8

|

10

|

10

|

10

|

12

|

|

Heating capacity(KW)

|

14.5

|

18.8

|

20.3

|

25

|

36

|

|

Total installed power(KW)

|

27.5

|

36.5

|

43

|

57

|

80

|

|

Extruding capacity per hour(kg/hr)

|

30

|

42

|

61

|

81

|

106

|

|

Dry cycle per hour(time/hr)

|

1030

|

880

|

720

|

650

|

650

|

|

Product capacity(c.c./L)

|

40-500

|

100-1250

|

280-1800

|

0.5L-2.5L

|

1L-5L

|

|

Product weight(g.)

|

5-40

|

10-100

|

20-170

|

40-170

|

100-160

|

|

Min./Max. diameter of product(m/m)

|

20-70

|

30-85

|

40-100

|

40-130

|

100-160

|

|

Extruding mouth outer diameter(m/m)

|

42

|

50

|

65

|

80

|

150

|

|

Mold center distance(m/m)

|

100

|

120

|

140

|

160

|

200

|

|

Clamping distance(m/m)

|

130-320

|

140-410

|

150-540

|

160-670

|

160-670

|

|

Length of mold capacity(m/m)

|

146-266

|

155-290

|

160-380

|

223-426

|

288-556

|

|

Width of mold capacity(m/m)

|

300

|

320

|

430

|

480

|

560

|

|

Machine net weight(kg)

|

3700

|

3900

|

4800

|

7700

|

8700

|

|

Machine dimension(m)

|

3*1.6*2.9

|

3*1.7*2.9

|

3.6*1.8*3.2

|

4.2*1.9*3.3

|

5.2*2.1*4.1

|

mẫu sản phẩm

Kìm khuôn di chuyển bằng phẳng bằng thanh trượt

thướt khuôn được thiết kế dạng cù trọ cong

hai kìm

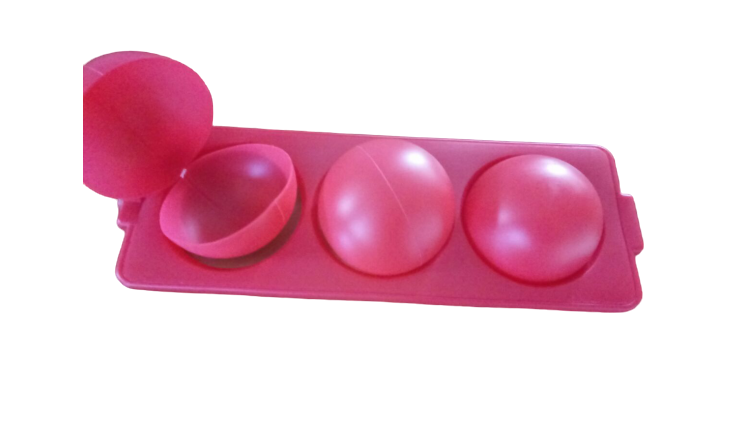

ỨNG DỤNG

Hand washing bottle / cleaning supplies

Water bottle or specific container

Mask/Closed Wound Drainage Systems

Household/Cleaning product bottle

Outdoor supplies/Bird balls

Closed Wound Drainage Systems

Household/Cleaning product bottle

20L Bucket (20L Jerry can)