MÁY THỔI NHỰA TỰ ĐỘNG Dòng sản phẩm O

Giới thiệu

-

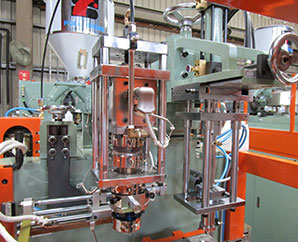

Loại máy Một đầu thổi hoặc hai đầu thổi và một kìm , thích hợp dùng để sản xuất các loại sản phẩm có đường cửa sổ (trên thân chai có một vạch trắng trong suốt vd như két dầu) ,còn có thể trang bị máy hệ thống băng tải tự động và máy kiểm tra sản phẩm ,để giám sát chất lượng sản phẩm.

- Đặc tính

- Machine Model

- Single Die-head/Single Station

- Double Die-head/Single Station

- Three Die-head/Single Station

- Four Die-head/Single Station

- Single Die-head/Double Station

- Double Die-head/Double Station

- Three Die-head/Double Station

- Four Die-head/Double Station

- Hình ảnh

- Video

-

Đặc tính

-

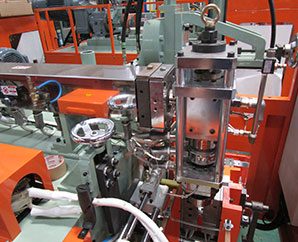

di chuyển khuôn bằng hình chữ V ,hình thức di chuyển sử dụng phối với hệ thống thuỷ lực.

-

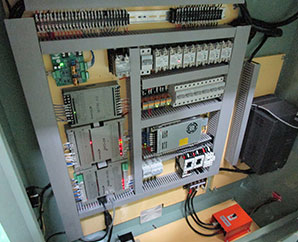

hệ thống điều khiển tự động PLC độc lập.

-

có thể trang bị máy cắt miệng chai tự động , băng tải , và bộ điều khiển dày mỏng(parison controller).

-

Thiết kế trục vít hiệu quả cao ,thích hợp dùng cho việc sản xuất các loại nhựa khác nhau.

-

Trang bị hệ thống phanh của FULL SHINE di chuyển khuôn , di chuyển ổn định,định vị chính xác.

|

|

|

EXPOSITION OF FULL SHINE'S MACHINE MODEL

|

|

|

SCREW DIAMETER(M/M)

|

MACHINE SERIES

|

MOLD HEAD(DIE HEAD)

|

MOLD STATION

|

PRODUCT TYPE

|

|

FS-

|

40

|

(H) Horizontal

|

(S) Single Mold Head

|

(S) Single Mold Station

|

(O) Original

|

|

45

|

(P) Parallel

|

(D) Double Mold Heads

|

(D) Double Mold Stations

|

(C) Two Colors

|

|

55

|

(O) Standard / Oblique

|

(T) Three Mold Heads

|

|

(D) Two Layers

|

|

65

|

(A) Pneumatic

|

(F) Four Mold Heads

|

|

(T) Three Layers

|

|

75

|

(L) Frontal

|

(E) Eight Mold Heads

|

|

(F) Four Layers

|

|

80

|

(I) Lateral

|

|

|

(L) Six Layers

|

|

90

|

|

|

|

(V) View Stripe

|

|

100

|

|

|

|

(P) PC baby bottle

|

|

Example

|

|

FS-

|

65

|

P

|

D

|

S

|

D

|

|

MODEL

|

FS-40 OSSO

|

FS-45 OSSO

|

FS-55 OSSO

|

FS-65 OSSO

|

FS-75 OSSO

|

|

Material

|

PE/PP

|

PE/PP

|

PE/PP

|

PE/PP

|

PE/PP

|

|

Screw diameter(m/m)

|

40

|

45

|

55

|

65

|

75

|

|

Screw L/D ratio(L/D)

|

24/1

|

24/1

|

24/1

|

24/1

|

24/1

|

|

Screw R.P.M speed(r.p.m.)

|

20-66

|

15-61

|

15-60

|

15-60

|

15-58

|

|

Inveter motor(HP)

|

5

|

7.5

|

10

|

15

|

25

|

|

Oil hydraulic drive motor(HP)

|

5

|

7.5

|

10

|

10

|

15

|

|

Optional air compressor(HP)

|

5

|

5

|

7.5

|

7.5

|

10

|

|

Air pressurer(kg/cm2)

|

4-6

|

4-6

|

4-6

|

5-7

|

5-7

|

|

Clamping force(Ton)

|

2.8

|

3.9

|

4.4

|

6.9

|

10

|

|

Oil tank capacity(Gallon)

|

38

|

55

|

60

|

80

|

120

|

|

Nunber of heaters(ZONE)

|

4

|

4

|

4

|

5

|

5

|

|

Heating capacity(KW)

|

7

|

9.5

|

12.5

|

16.8

|

18

|

|

Total installed power(KW)

|

15

|

21

|

30

|

35

|

48

|

|

Extruding capacity per hour(kg/hr)

|

15

|

24

|

36

|

55

|

75

|

|

Dry cycle per hour(time/hr)

|

1285

|

1030

|

880

|

720

|

650

|

|

Product capacity(c.c./L)

|

15-500

|

60-1000

|

150-2500

|

500-5000

|

1L-10L

|

|

Product weight(g.)

|

5-40

|

10-100

|

20-170

|

40-280

|

80-500

|

|

Min./Max. diameter of product(m/m)

|

10-75

|

20-100

|

30-140

|

50-200

|

80-260

|

|

Extruding mouth outer diameter(m/m)

|

50

|

56

|

80

|

150

|

200

|

|

Mold center distance(m/m)

|

*

|

*

|

*

|

*

|

*

|

|

Clamping distance(m/m)

|

120-230

|

130-320

|

140-410

|

150-540

|

160-670

|

|

Length of mold capacity(m/m)

|

100-210

|

126-232

|

156-292

|

200-380

|

240-421

|

|

Width of mold capacity(m/m)

|

200

|

290

|

306

|

350

|

425

|

|

Machine net weight(kg)

|

2200

|

2700

|

3200

|

4100

|

7000

|

|

Machine dimension(m)

|

2.3*1.4*2.2

|

3*1.4*2.3

|

3*1.5*2.3

|

3*1.6*2.6

|

4.2*1.7*2.7

|

|

MODEL

|

FS-40 ODSO

|

FS-45 ODSO

|

FS-55 ODSO

|

FS-65 ODSO

|

FS-75 ODSO

|

|

Material

|

PE/PP

|

PE/PP

|

PE/PP

|

PE/PP

|

PE/PP

|

|

Screw diameter(m/m)

|

40

|

45

|

55

|

65

|

75

|

|

Screw L/D ratio(L/D)

|

24/1

|

24/1

|

24/1

|

24/1

|

24/1

|

|

Screw R.P.M speed(r.p.m.)

|

20-66

|

15-61

|

15-60

|

15-60

|

15-58

|

|

Inveter motor(HP)

|

5

|

7.5

|

10

|

15

|

40

|

|

Oil hydraulic drive motor(HP)

|

5

|

7.5

|

10

|

10

|

20/15

|

|

Optional air compressor(HP)

|

5

|

5

|

7.5

|

7.5

|

10

|

|

Air pressurer(kg/cm2)

|

4-6

|

4-6

|

4-6

|

5-7

|

5-7

|

|

Clamping force(Ton)

|

2.8

|

3.9

|

4.4

|

6.9

|

10

|

|

Oil tank capacity(Gallon)

|

38

|

55

|

60

|

80

|

120

|

|

Nunber of heaters(ZONE)

|

6

|

6

|

7

|

8

|

9

|

|

Heating capacity(KW)

|

7.5

|

10.25

|

13.6

|

17.5

|

25

|

|

Total installed power(KW)

|

15

|

21

|

30

|

35

|

48

|

|

Extruding capacity per hour(kg/hr)

|

15

|

24

|

36

|

55

|

75

|

|

Dry cycle per hour(time/hr)

|

1285

|

1030

|

880

|

720

|

650

|

|

Product capacity(c.c./L)

|

15-500

|

40-500

|

100-1250

|

280-1800

|

0.5L-2.5L

|

|

Product weight(g.)

|

4-25

|

5-40

|

10-100

|

20-170

|

40-170

|

|

Min./Max. diameter of product(m/m)

|

10-65

|

20-70

|

30-85

|

40-100

|

40-130

|

|

Extruding mouth outer diameter(m/m)

|

38

|

42

|

50

|

65

|

80

|

|

Mold center distance(m/m)

|

85

|

100

|

120

|

140

|

180

|

|

Clamping distance(m/m)

|

120-230

|

130-320

|

140-410

|

150-540

|

160-670

|

|

Length of mold capacity(m/m)

|

100-210

|

126-232

|

156-292

|

200-380

|

240-421

|

|

Width of mold capacity(m/m)

|

200

|

290

|

306

|

350

|

425

|

|

Machine net weight(kg)

|

2200

|

2700

|

3200

|

4100

|

7000

|

|

Machine dimension(m)

|

2.3*1.4*2.2

|

3*1.4*2.3

|

3*1.5*2.3

|

3*1.6*2.6

|

4.2*1.7*2.7

|

|

MODEL

|

FS-40 OTSO

|

FS-45 OTSO

|

FS-55 OTSO

|

FS-65 OTSO

|

FS-75 OTSO

|

|

Material

|

PE/PP

|

PE/PP

|

PE/PP

|

PE/PP

|

PE/PP

|

|

Screw diameter(m/m)

|

40

|

45

|

55

|

65

|

75

|

|

Screw L/D ratio(L/D)

|

24/1

|

24/1

|

24/1

|

24/1

|

24/1

|

|

Screw R.P.M speed(r.p.m.)

|

20-66

|

15-61

|

15-60

|

15-60

|

15-58

|

|

Inveter motor(HP)

|

5

|

7.5

|

10

|

15

|

25

|

|

Oil hydraulic drive motor(HP)

|

5

|

7.5

|

10

|

10

|

15

|

|

Optional air compressor(HP)

|

7.5

|

7.5

|

10

|

10

|

15

|

|

Air pressurer(kg/cm2)

|

4-6

|

4-6

|

5-7

|

5-7

|

5-7

|

|

Clamping force(Ton)

|

2.8

|

3.9

|

4.4

|

6.9

|

10

|

|

Oil tank capacity(Gallon)

|

38

|

55

|

60

|

80

|

120

|

|

Nunber of heaters(ZONE)

|

8.5

|

12

|

15

|

19.3

|

21.5

|

|

Heating capacity(KW)

|

7.5

|

10.25

|

13.6

|

17.5

|

25

|

|

Total installed power(KW)

|

16.5

|

23.5

|

32

|

39

|

52.5

|

|

Extruding capacity per hour(kg/hr)

|

15

|

24

|

36

|

55

|

75

|

|

Dry cycle per hour(time/hr)

|

1250

|

1000

|

850

|

720

|

650

|

|

Product capacity(c.c./L)

|

10-125

|

20-325

|

40-825

|

100-1000

|

180-4500

|

|

Product weight(g.)

|

3-10

|

5-25

|

10-50

|

10-90

|

15-145

|

|

Min./Max. diameter of product(m/m)

|

10-45

|

20-55

|

30-55

|

30-80

|

95

|

|

Extruding mouth outer diameter(m/m)

|

30

|

37

|

40

|

55

|

80

|

|

Mold center distance(m/m)

|

75+75

|

85+85

|

100+100

|

120+120

|

120+120

|

|

Clamping distance(m/m)

|

120-230

|

130-320

|

140-410

|

150-540

|

160-670

|

|

Length of mold capacity(m/m)

|

100-210

|

126-232

|

156-292

|

200-380

|

243-466

|

|

Width of mold capacity(m/m)

|

200

|

290

|

306

|

350

|

425

|

|

Machine net weight(kg)

|

2500

|

3100

|

3600

|

4600

|

7500

|

|

Machine dimension(m)

|

2.3*1.4*2.2

|

3*1.4*2.3

|

3*1.5*2.3

|

3*1.6*2.6

|

4.2*1.7*2.7

|

|

MODEL

|

FS-55 OFSO

|

FS-65 OFSO

|

FS-75 OFSO

|

FS-90 OFSO

|

|

Material

|

PE/PP

|

PE/PP

|

PE/PP

|

PE/PP

|

|

Screw diameter(m/m)

|

55

|

65

|

75

|

90

|

|

Screw L/D ratio(L/D)

|

24/1

|

24/1

|

24/1

|

28/1

|

|

Screw R.P.M speed(r.p.m.)

|

15-60

|

15-60

|

15-58

|

15-58

|

|

Inveter motor(HP)

|

15

|

20

|

30

|

50

|

|

Oil hydraulic drive motor(HP)

|

10

|

15

|

15

|

15

|

|

Optional air compressor(HP)

|

15

|

15

|

20

|

20

|

|

Air pressurer(kg/cm2)

|

6-8

|

6-8

|

6-8

|

6-8

|

|

Clamping force(Ton)

|

4.4

|

6.9

|

10

|

13

|

|

Oil tank capacity(Gallon)

|

60

|

80

|

120

|

250

|

|

Nunber of heaters(ZONE)

|

11

|

13

|

13

|

15

|

|

Heating capacity(KW)

|

16.5

|

20.8

|

25.7

|

30

|

|

Total installed power(KW)

|

37.5

|

48

|

61

|

80

|

|

Extruding capacity per hour(kg/hr)

|

36

|

55

|

75

|

100

|

|

Dry cycle per hour(time/hr)

|

750

|

750

|

650

|

650

|

|

Product capacity(c.c./L)

|

30-300

|

100-500

|

300-1000

|

500-2500

|

|

Product weight(g.)

|

10-25

|

10-40

|

15-90

|

40-170

|

|

Min./Max. diameter of product(m/m)

|

20-55

|

30-55

|

30-90

|

30-90

|

|

Extruding mouth outer diameter(m/m)

|

37

|

42

|

50

|

75

|

|

Mold center distance(m/m)

|

85+85+85

|

85+85+85

|

120+120+120

|

120+120+120

|

|

Clamping distance(m/m)

|

140-410

|

150-540

|

160-670

|

200-780

|

|

Length of mold capacity(m/m)

|

156-292

|

200-380

|

243-466

|

250-550

|

|

Width of mold capacity(m/m)

|

380

|

430

|

510

|

550

|

|

Machine net weight(kg)

|

3800

|

4800

|

7900

|

8900

|

|

Machine dimension(m)

|

3.1*1.8*2.3

|

3.2*1.9*2.6

|

4.3*2*2.7

|

5.2*3.1*3.5

|

|

MODEL

|

FS-45 OSDO

|

FS-55 OSDO

|

FS-65 OSDO

|

FS-75 OSDO

|

|

Material

|

PE/PP

|

PE/PP

|

PE/PP

|

PE/PP

|

|

Screw diameter(m/m)

|

45

|

55

|

65

|

75

|

|

Screw L/D ratio(L/D)

|

24/1

|

24/1

|

24/1

|

24/1

|

|

Screw R.P.M speed(r.p.m.)

|

15-61

|

15-60

|

15-60

|

15-58

|

|

Inveter motor(HP)

|

7.5

|

10

|

15

|

30

|

|

Oil hydraulic drive motor(HP)

|

7.5

|

10

|

10

|

15

|

|

Optional air compressor(HP)

|

10

|

15

|

15

|

20

|

|

Air pressurer(kg/cm2)

|

4-6

|

4-6

|

5-7

|

5-7

|

|

Clamping force(Ton)

|

3.9

|

4.4

|

6.9

|

10

|

|

Oil tank capacity(Gallon)

|

60

|

80

|

120

|

250

|

|

Nunber of heaters(ZONE)

|

4

|

4

|

5

|

5

|

|

Heating capacity(KW)

|

9.5

|

12.5

|

16.8

|

18

|

|

Total installed power(KW)

|

22

|

28

|

37

|

53

|

|

Extruding capacity per hour(kg/hr)

|

24

|

36

|

55

|

75

|

|

Dry cycle per hour(time/hr)

|

1030*2

|

880*2

|

720*2

|

650*2

|

|

Product capacity(c.c./L)

|

40-500

|

65-1250

|

150-2500

|

500-5000

|

|

Product weight(g.)

|

5-40

|

10-100

|

20-170

|

40-280

|

|

Min./Max. diameter of product(m/m)

|

10-75

|

20-100

|

30-140

|

50-280

|

|

Extruding mouth outer diameter(m/m)

|

56

|

80

|

150

|

200

|

|

Mold center distance(m/m)

|

*

|

*

|

*

|

*

|

|

Clamping distance(m/m)

|

120-320

|

140-410

|

150-540

|

160-670

|

|

Length of mold capacity(m/m)

|

126-232

|

156-292

|

200-380

|

240-640

|

|

Width of mold capacity(m/m)

|

250

|

280

|

380

|

420

|

|

Machine net weight(kg)

|

6400

|

6900

|

7400

|

8300

|

|

Machine dimension(m)

|

3*1.8*2.5

|

3.2*1.9*2.5

|

3.2*2*2.8

|

4.2*2.1*2.9

|

|

MODEL

|

FS-45 OSDO

|

FS-55 OSDO

|

FS-65 OSDO

|

FS-75 OSDO

|

|

Material

|

PE/PP

|

PE/PP

|

PE/PP

|

PE/PP

|

|

Screw diameter(m/m)

|

45

|

55

|

65

|

75

|

|

Screw L/D ratio(L/D)

|

24/1

|

24/1

|

24/1

|

24/1

|

|

Screw R.P.M speed(r.p.m.)

|

15-61

|

15-60

|

15-60

|

15-58

|

|

Inveter motor(HP)

|

10

|

10

|

15

|

30

|

|

Oil hydraulic drive motor(HP)

|

7.5

|

10

|

10

|

15

|

|

Optional air compressor(HP)

|

10

|

15

|

15

|

20

|

|

Air pressurer(kg/cm2)

|

4-6

|

4-6

|

5-7

|

5-7

|

|

Clamping force(Ton)

|

3.9

|

4.4

|

6.9

|

10

|

|

Oil tank capacity(Gallon)

|

60

|

80

|

120

|

160

|

|

Nunber of heaters(ZONE)

|

6

|

7

|

8

|

8

|

|

Heating capacity(KW)

|

10.25

|

13.6

|

17.5

|

19

|

|

Total installed power(KW)

|

26

|

30

|

38

|

54

|

|

Extruding capacity per hour(kg/hr)

|

24

|

36

|

55

|

75

|

|

Dry cycle per hour(time/hr)

|

1030*2

|

880*2

|

720*2

|

650*2

|

|

Product capacity(c.c./L)

|

30-200

|

40-500

|

100-1000

|

280-2000

|

|

Product weight(g.)

|

4-20

|

5-40

|

10-65

|

20-110

|

|

Min./Max. diameter of product(m/m)

|

10-65

|

20-70

|

30-85

|

40-110

|

|

Extruding mouth outer diameter(m/m)

|

42

|

50

|

65

|

80

|

|

Mold center distance(m/m)

|

100

|

120

|

140

|

160

|

|

Clamping distance(m/m)

|

130-320

|

140-410

|

150-540

|

160-670

|

|

Length of mold capacity(m/m)

|

126-232

|

156-292

|

200-380

|

243-466

|

|

Width of mold capacity(m/m)

|

250

|

280

|

380

|

420

|

|

Machine net weight(kg)

|

6500

|

7000

|

7500

|

8500

|

|

Machine dimension(m)

|

3*1.8*2.5

|

3.2*2*2.8

|

3.4*3*3

|

4.2*3.1*3.1

|

|

MODEL

|

FS-55 OTDO

|

FS-65 OTDO

|

FS-75 OTDO

|

|

Material

|

PE/PP

|

PE/PP

|

PE/PP

|

|

Screw diameter(m/m)

|

55

|

65

|

75

|

|

Screw L/D ratio(L/D)

|

24/1

|

24/1

|

24/1

|

|

Screw R.P.M speed(r.p.m.)

|

15-60

|

15-60

|

15-58

|

|

Inveter motor(HP)

|

10

|

15

|

30

|

|

Oil hydraulic drive motor(HP)

|

10

|

10

|

15

|

|

Optional air compressor(HP)

|

15

|

15

|

20

|

|

Air pressurer(kg/cm2)

|

4-6

|

5-7

|

5-7

|

|

Clamping force(Ton)

|

4.4

|

5.7

|

5.7

|

|

Oil tank capacity(Gallon)

|

80

|

120

|

160

|

|

Nunber of heaters(ZONE)

|

9

|

10

|

10

|

|

Heating capacity(KW)

|

15

|

19.3

|

21.5

|

|

Total installed power(KW)

|

32

|

40

|

56.5

|

|

Extruding capacity per hour(kg/hr)

|

36

|

55

|

75

|

|

Dry cycle per hour(time/hr)

|

850*2

|

720*2

|

650*2

|

|

Product capacity(c.c./L)

|

15-300

|

50-600

|

100-1000

|

|

Product weight(g.)

|

5-25

|

8-45

|

10-70

|

|

Min./Max. diameter of product(m/m)

|

10-55

|

20-70

|

30-90

|

|

Extruding mouth outer diameter(m/m)

|

40

|

55

|

80

|

|

Mold center distance(m/m)

|

85+85

|

100+100

|

120+120

|

|

Clamping distance(m/m)

|

140-410

|

150-540

|

160-670

|

|

Length of mold capacity(m/m)

|

156-292

|

200-380

|

243-466

|

|

Width of mold capacity(m/m)

|

300

|

380

|

420

|

|

Machine net weight(kg)

|

7100

|

7600

|

8700

|

|

Machine dimension(m)

|

3.4*2*2.8

|

3.6*3*3

|

4.4*3.1*3.1

|

|

MODEL

|

FS-55 OFDO

|

FS-65 OFDO

|

FS-75 OFDO

|

|

Material

|

PE/PP

|

PE/PP

|

PE/PP

|

|

Screw diameter(m/m)

|

55

|

65

|

75

|

|

Screw L/D ratio(L/D)

|

24/1

|

24/1

|

24/1

|

|

Screw R.P.M speed(r.p.m.)

|

15-60

|

15-60

|

15-58

|

|

Inveter motor(HP)

|

15

|

20

|

30

|

|

Oil hydraulic drive motor(HP)

|

10

|

10

|

15

|

|

Optional air compressor(HP)

|

15

|

15

|

20

|

|

Air pressurer(kg/cm2)

|

6-8

|

6-8

|

6-8

|

|

Clamping force(Ton)

|

4.4

|

6.9

|

13

|

|

Oil tank capacity(Gallon)

|

80

|

120

|

160

|

|

Nunber of heaters(ZONE)

|

11

|

13

|

13

|

|

Heating capacity(KW)

|

16.5

|

20.8

|

25.7

|

|

Total installed power(KW)

|

37.5

|

48

|

61

|

|

Extruding capacity per hour(kg/hr)

|

36

|

55

|

75

|

|

Dry cycle per hour(time/hr)

|

750*2

|

750*2

|

650*2

|

|

Product capacity(c.c./L)

|

50-250

|

100-400

|

200-600

|

|

Product weight(g.)

|

5-20

|

10-30

|

20-50

|

|

Min./Max. diameter of product(m/m)

|

20-55

|

20-55

|

20-70

|

|

Extruding mouth outer diameter(m/m)

|

37

|

42

|

50

|

|

Mold center distance(m/m)

|

85+85

|

85+85

|

120+120

|

|

Clamping distance(m/m)

|

140-410

|

150-410

|

160-670

|

|

Length of mold capacity(m/m)

|

156-292

|

200-380

|

243-466

|

|

Width of mold capacity(m/m)

|

410

|

460

|

520

|

|

Machine net weight(kg)

|

7200

|

7700

|

8900

|

|

Machine dimension(m)

|

3.4*2*3

|

3.6*3.2*3.2

|

4.4*3.3*3.3

|

mẫu sản phẩm

mẫu sản phẩm

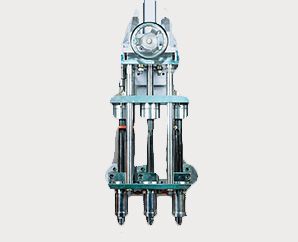

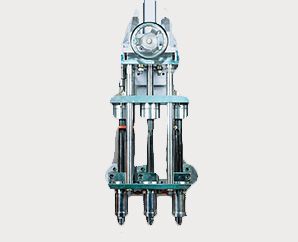

hệ thống thổi xuống

hệ thống phanh

ỨNG DỤNG

Hand washing bottle / cleaning supplies

Water bottle or specific container

Mask/Closed Wound Drainage Systems

Household/Cleaning product bottle

Outdoor supplies/Bird balls

Closed Wound Drainage Systems

Household/Cleaning product bottle